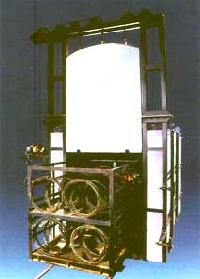

Shaker Hearth Heat Treatment Furnace

Get Price Quote

Shaker Hearth Heat Treatment Furnace in fact called Reciprocating and Rotary Agitation write Furnaces while responding shaker movement bestows idleness to the work plate display in the hearth of the heater with uniform warming to the principle workload general case profundity warm is accomplished. The Furnace are by and large utilized for the light weight parts that are to be carburized to case profundity of 0.3 mm. Shaker hearth heaters utilize a plate for the vehicle of Work pieces from a bay zone to a release zone, and such plate are ordinarily upheld inside the heater upon metal or headstrong slides or upon rollers or notwithstanding holding tight arms. Such kinds of backings are liable to very fast Wear and their restoration requires expulsion from the Furnace. Primary Process of the Furnace: Austempering : increment quality, sturdiness, and diminish mutilation. Solidifying: increment the hardness of a metal for better protection. Remarkable Features: Pleasantly Welded and Painted Mild Steel Structure with appropriately strengthened with reasonable size of edge and channel. Shaking Tray is made out of Stainless Steel 310 review which can manage top of the line operational stun. Heater is given the programmed control board for the operation. Steady temperature in heater because of subdivision of heater in to warming drenching zones. Segment Processed: High Carbon clasp. Hand devices, spanners, bearing, chain, locks, vehicle parts and so on. Solidifying of little utensils parts. Austempering of auto-segments. Solidifying of protection Alloys. Extra Information: Thing Code: HTF-7 Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer) Port of Dispatch: Nhava Sheva, Kandla Port Generation Capacity: 4-8 every year Conveyance Time: 30 days Bundling Details: High Quality Plastic Wrap Wooden Box with Fumigation

Shaker Hearth Heat Treatment Furnace

Get Price Quote

Shaker Hearth Heat Treatment Furnace in fact called Reciprocating and Rotary Agitation write Furnaces while responding shaker movement bestows idleness to the work plate display in the hearth of the heater with uniform warming to the principle workload general case profundity warm is accomplished. The Furnace are by and large utilized for the light weight parts that are to be carburized to case profundity of 0.3 mm. Shaker hearth heaters utilize a plate for the vehicle of Work pieces from a bay zone to a release zone, and such plate are ordinarily upheld inside the heater upon metal or headstrong slides or upon rollers or notwithstanding holding tight arms. Such kinds of backings are liable to very fast Wear and their restoration requires expulsion from the Furnace. Primary Process of the Furnace: Austempering : increment quality, sturdiness, and diminish mutilation. Solidifying: increment the hardness of a metal for better protection. Remarkable Features: Pleasantly Welded and Painted Mild Steel Structure with appropriately strengthened with reasonable size of edge and channel. Shaking Tray is made out of Stainless Steel 310 review which can manage top of the line operational stun. Heater is given the programmed control board for the operation. Steady temperature in heater because of subdivision of heater in to warming drenching zones. Segment Processed: High Carbon clasp. Hand devices, spanners, bearing, chain, locks, vehicle parts and so on. Solidifying of little utensils parts. Austempering of auto-segments. Solidifying of protection Alloys. Extra Information: Thing Code: HTF-7 Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer) Port of Dispatch: Nhava Sheva, Kandla Port Generation Capacity: 4-8 every year Conveyance Time: 30 days Bundling Details: High Quality Plastic Wrap Wooden Box with Fumigation

Best Deals from Shaker Hearth Furnaces

Shaker Hearth Furnaces

Get Price Quote

Process Capabilities: Hardening Austempering For bright heat treatment of steel parts, Shaker Hearth Furnace is most efficient and versatile unit for incorporation into continuous production line. Due to high temperature uniformity & thermal efficiency consistent results are assured. Available in different capacities & specifications, depending upon component. Salient Features: Furnace made out of rigid & durable structure to sustain operational shocks. The shaker plate made of heat resistant austenitic steel is designed to handle a wide range of components. The components progresses in a series of adjustable short steps ensuring consistent results. The only atmosphere escape is at the entry vestibule which reduces gas consumption. The shaker plate stays inside the furnace in the form of hot plate resulting higher thermal efficiency, as compared to conveyor furnaces. Uniform temperature due to sub-divisions of furnace in to heating & soaking zones. Component Processed: High tensile fasteners Hand tools, circlips, bearing, chain, locks, auto parts etc Hardening of small delicate parts Austempering of auto-components