SS Handa Mixer Machine

55,000 Per Piece

1 Piece(s) (MOQ)

Turmeric Powder Packing Machine

350,000 Per Unit

Best Deals from Spice Processing Plant

Aluminium Dross Impact Pulverizer

600,000 Per Piece

1 Piece(s) (MOQ)

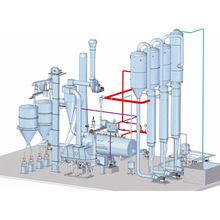

Vacuum Salt Refinery

Get Price Quote

The process involves dissolving of salt in water and making a saturated solution of salt. The saturated brine is pumped out to a brine clarifier, where the insoluble settles at the bottom of the clarifier and clear brine solution is taken to a brine tank. In the brine tank required chemicals are added to precipitate out magnesium and calcium salts present along with the salt. The brine is then filtered and taken to the final brine tank. From this tank saturated brine is fed to the continuous evaporation plant where Crystallization takes place and slurry is pumped out to a concentrate tank. This salt slurry is then pumped to a hydro-cyclone battery to get a slurry concentration up to 50-60%. This slurry is fed to a centrifuge, and from the centrifuge salt cakes with 4-5% moisture comes out. The salt with 4-5% moisture is fed to a fluid bed dryer through a screw conveyor where the iodization is completed.

Impact Pulverizer

Get Price Quote

Impact Pulverizer, Metal Disintegrators, Candy Packing Machine

Chilli Cleaning Machine

Get Price Quote

Chilli Cleaning Machine, seed coating machine, Screw Conveyor, Vibro Screen

Masala Processing Plant

Get Price Quote

Masala Processing Plant, Food Processing Plant Machinery

starch processing plant

Get Price Quote

starch processing plant, Milk powder plant, Evaporated Milk Plant

salt refinery plant

Get Price Quote

salt refinery plant, Engineering Equipments, Aroma Recovery System

Starch Glucose Plant

Get Price Quote

Starch Glucose Plant, Milk powder plant, Coconut Milk Processing Plant