Pulveriser Hammer Type Machine

90,000 Per piece

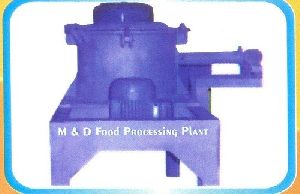

Impact Pulverizer

250,000 Per Piece

Our company’s name figures in the list of reliable Manufacturers, Suppliers and Exporters of Impact Pulverizer from Haryana. The Impact Pulverizer we make available are manufactured using advanced technology and quality-tested components. Our Impact Pulverizer is suitable and convenient to pulverize the material up to 100 -250 mesh. Owing to our brilliant logistics network, we are capable of delivering bulk orders of the Impact Pulverizer. Features: Hammer and Liners are available in different shapes and construction like MS, Hi Mn Steel hardened alloy steel, stainless steel etc., to suit the material Most suitable and convenient range to pulverize the material up to 100 -250 mesh Robustly constructed machine for crushing different spice, chemicals, Ayurvedic Herbs, Agro Products Used without cyclone and dust collector for bigger output particle size and for fine material, a cyclone with dust collector is used Different type of material for liners and hammer as per client product for better result and best life of wear & tear Applications : Fertilizers Dyestuffs Chemical products Insecticides & pesticides Mineral Pigments colours Metal separation Spices Refractory Ceramics Dolomite Lime stone Coal Alluminium Dross

Best Deals from Spices Processing Machinery

Spices Masala Grinding Machine

900,000 - 3,500,000 Per Set

01 Set(s) (MOQ)

ACM Spice Grinding machines that works best to maintain flavor aroma and color of any Spice, as these two characteristics are the Strength any spice. Ourmachines are designed and manufactured adeptly under the supervision of technically adept expects tomaintain spice's basic essentials, i.e; the real flavor of spices even after grinding.Usually, volatile substances of any spice, whether it's oil or soluble organic solvents evaporates at atemperature above 30 DegreeC. But, it's not an issue with our ACM spice grinding machines. Aroma and color ofspices are maintained even at a temperature above 60 DegreeC and can be maintained up to 80 DegreeC. Our spicegrinding machines can easily grind materials in different sizes in one go.We provide machinery that is available in different sizes and capacities as well to meet every changingperquisites of our customer's belonging to this industry.Some Salient Features of Our ACM Spice Grinding Machinery are asfollows1. Our quality ACM spice grinding machines demands low power consumptions.2. Our machines are eco-friendly and thus provide better working conditions.3. They are best pickup options for grinding at even low temperature.4. With our machines, there's 0% loss and 100% recovery of material's weight5. Both, end products and impurities are collected separately with the help of discharge tubes.6. Our grinding machines have inbuilt cleaning system to maintain standards of performance.7. All machinery meets basic safety parameters and maintains industrial norms in the best possibleways.8. All components of our ACM Spice Grinding Machines gone through a quality test to maintain basicstandards. RequestCallback Additional Information Item CodeACM Pay Mode TermsL/C (Letter of Credit) Production Capacity50 TO 1000 KG PER HOUR. Delivery Time45-60 DAYS Packaging DetailsEXPORT WOODEN BOX

Automatic Chilli Cleaning Machine

4 Per Piece

1 Piece(s) (MOQ)

impact pulverizer machine

Get Price Quote

This machine is manufactured by a team of our adroit professionals using quality assured components at highly advanced premises. The offered machine is used for grinding of different types of materials such as spices, grains and pulses.

ACM Spice Grinding Machine

Get Price Quote

Industrial acm grinding machine works in a way that the characteristic flavor aroma and color of spices are same due to steam volatile essential or volatile oils and organic solvent soluble oleoresins, which is the strength of the spices. These volatile substances start evaporating at a temperature above 30°c. In ordinary hammer mill or beater type pulverizer is used in which temperature of the product goes up to 60 to 80°c, which affects quality and flavor of spices. In addition to this additional cooling is required before packaging of the final products. Sifter international acm spice grinding machinery has got solution to this problem in our acm series or micro pulverizer and perfect technology for grinding of spices. It will produce the exact desired finished size while preserving aroma and volatile oil qualities. Machine is available in various capacities. Specialty of this machine is that it can grind the material in your desired mesh size in a single grinding. Complete grinding unit can be put on plc system without any trained technician.

spices processing machinery

Get Price Quote

Using this spices processing line you get the spices powder as product by processing the different types of whole spices. This is fully automatic line, just feed the spices like turmeric, cumin, coriander, etc. in hopper and the whole process is done automatically.The crusher contains two rotary blades that rotates in opposite directions, the spices are fed between the blades and cut into small pieces.Pin Mill reduces the average sized material to fine powder and maintains the quality of material. It uses air cooling to maintain the temperature of the final product . There are two rotating disks with pinsknifes, the substance that is to be grinded, is fed into the space between disks and through the grinding motion of the disks the material is converted into powder.

Masala Making Machine

Get Price Quote

Pulverizer Hammer

750 Per Piece

starch processing plant

Get Price Quote

Impact Type Pulverizer

Get Price Quote

This Impact Type Pulverizer has been constructed in a way to make it strong and deliver more. It has been designed in a way to finely grind soft as well as semi hard materials without an effort. This machine can be used in various fields and industries. It provides exceptional delivery with utmost efficiency. This Impact Type Pulverizer is manufactured with latest technology and is available with a number of specifications as per the requirements of the clients. Post the manufacturing process, every level is scrutinized and tested deftly. No parameter in the manufacturing process is compromised, be it quality or the components used; and all the components used are of the best quality. This Impact Type Pulverizer comes with supreme designs and the resistance to wear and tear is unparalleled. This is the reason why this machine has huge requirement and high appeal. Following this huge demand, we are producing these Impact Type Pulverizers in bulk, making sure each and every batch is complete in itself in terms of quality, strength, efficiency and manageability. This Pulverizer can be used for a number of applications, be it in agriculture or other industries. It doesn’t cause any blockage when it is in operation mode. The entire process is completely environment friendly and no dust will be found even post the operation. With a long service life, this Impact Type Pulverizer will help the industry in a miraculous way. Available at completely affordable prices, this pulverizer gives a fine result and the operation performed is so easy that any unskillful labor could do the required work. Features Most favorable price Excellent specifications Superlative technology used Compact design Good performance

Chilli Cleaning Machine

Get Price Quote

Chilli Cleaning Machine, seed coating machine, Vibro Screen, Plan Sifter

hammer mill pulverizer

Get Price Quote

hammer mill pulverizer, Ribbon Blender Mixer machine, Hot Air Oven

Impact Pulverizer

Get Price Quote

Impact Pulverizer, Packaging Machines, Wrapping Machines

Impact Pulverizer

Get Price Quote

Impact Pulverizer, Metal Disintegrators, Candy Packing Machine

Masala Making Machine

Get Price Quote

Masala Making Machine

Get Price Quote

Air Classifiers, Guar Gum Powder machinery, Gloriosa Superba Seeds

Industrial Spice Grinding Machine

Get Price Quote

Industrial Spice Grinding Machine, Hammer Mill Shredder

Chilly

Get Price Quote

Cumin Seed, Spices

starch processing plant

Get Price Quote

starch processing plant, Milk powder plant, Evaporated Milk Plant