Water Softener

Get Price Quote

100 Kilogram (MOQ)

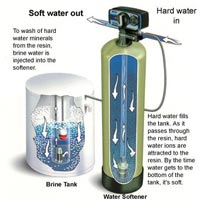

We are one of the most reliable Manufacturers and Suppliers of Water Softener in India. Water Softener uses resin based technology for the softening of water, as it is quite inexpensive. Water Softener also regenerates the common salt after the process. The installation of our Water Softener is quite easy, which is appreciated by a lot of our clients. The maintenance cost of our Water Softener is also very minimal. Process : To wash of hard water minerals from the resin, brine water is injected into the softener. Hard water fills the tank. As is passes through the resin, hard water ions are attracted to the resin. By the time water gets to the bottom of the tank, it's soft. Highlights : Durable Easy to operate Low maintenance Simple installation

Industrial Water Softener

20,000 Per Piece

Best Deals from Water Softening System

Water Softening Plant

Get Price Quote

We provide Water Softening Plant, which is used to soften water, by removing the minerals that cause the water to be hard. We are a famous Water Softening Plant Manufacturer and Supplier in India. Water softening is an important process, because the hardness of water in different applications is reduced during this process. When water is hard, it can clog pipes, damage boilers, heat exchangers, and many other devices. Water softening can prevent these negative effects.

Water Softener Plant

Get Price Quote

01 Piece(s) (MOQ)

We are a renowned water softener plant manufacturer and supplier, based in faridabad, haryana. Basically, hardness in water is due to the presence of ions, calcium and magnesium, which gets deposited in pipelines, boiler tubes, condenser jackets, circulation systems, heat exchangers, etc. Thus to avoid corrosion and malfunctioning of the equipment, we are offering a range of water softener plants. The water softener plant that we manufacture is primarily used to produce zero soft water. Our water softener plant is highly durable, reliable and affordable. features are designed both for counter current regeneration with up flow rate as well as co-current regeneration with down flow rate are suitable for residential, commercial and industrial use have highly acidic cat ion exchanger, which exchanges calcium and magnesium ions with sodium ions are designed for longer operating cycles, low regeneration cost applications homes hospitals hotels ice plants boilers and cooling water feed. process water for water feed. commercial & institutional water plants

Electronic Water Conditioner

36,999 - 37,000 Per

First time in India advance electronic water conditioner no plumbering charge storage tank electrolysis water up to 10000 liters automatic power setting automatic timer setting

Water Softening Plant

Get Price Quote

We offer a wide assortment of Softening Plants to our esteemed clients as per their various requirements of our clients. These plants are used to remove calcium, magnesium and other metal cations from hard water. Our proposed products are designed with utmost care and highly in demand all over the nation. Clients can avail these high quality products from us at very affordable prices.

Softener Plant

45,000 Per Piece

2 Piece (MOQ)

Water Softener Plant

Get Price Quote

We are a trusted Manufacturer, Exporter and Supplier of Water Softener Plant. Water softeners are specific ion exchangers equipment. Water Softener Plant is used to soften the water, by removing the minerals that cause the water to be hard. Minerals like calcium and magnesium present in the water in their carbonates and bi-carbonates form makes the water hard, which creates many problems when it is used in industrial as well as in other domestic purposes. We are accredited as one of the largest water softener plant manufacturers of India. More About Information for Water Softener Plant Water Softening Plant uses Ion Exchange process, which relies on the replacement of the Calcium, and Magnesium ions present in the water by an equivalent number of Sodium ions. This eliminates the unwanted characteristics of hard water because the sodium salts never forms scale in any of the machinery parts. The resins get charged by sodium chloride solution (common salt) which is the cost effective and easiest maintenance process. Pure Drops offers water-softening systems in various sizes for home, restaurant and many more industrial applications.

Industrial Water Softeners

Get Price Quote

We Design and Supply Industrial Water Softeners where calcium, magnesium ions are exchanged for sodium ions. These are manually and automatically operated and designed to suit the requirement of process water in industries such as textile mills, beverage manufacture, laundry and air conditioning plants, boiler feed etc.

Kent Water Softener

65,000 Per Piece

5 Piece (MOQ)

Water Treatment Post Conditioning System

4,000 Per Piece

Water Softening System

Get Price Quote

Our Softeners help in taking out the hardness of water and comprise high performance resins for higher transfer rate. Automatic, semi-automatic and manual operated softeners Demineralisers are designed to suit concerning raw water and water results. The reverse osmosis plant ensures water with more quality to effectively meet up the norms of WHO and BIS, and utilized in the process water industries, Thus the calcium and magnesium ions responsible for the hardness in the water are replaced by the less harmful and acceptable sodium ion thereby making the water soft. As there is an exchange of cations with a preference for the sodium ion, a cation exchange resin in the sodium form is used in the process.

Water Softener

Get Price Quote

Our Water Softener removes or renders inactive and isolate minerals, such as Calcium, Magnesium fro Hard Water. Water containing dissolved calcium and magnesium in amount greater than 120mg. /1 is considered hard, this water destroys the detergent property of soaps. On heating & cooling, it forms scales which corrode. Our Water Softener is made using premium quality of raw materials and is widely demanded in the global markets. We also offer to design it as per the required technical specifications. Moreover, these are easy to install. Saves you from ill effects of hard water like Damage to water related appliances like water heater, pipes, dishwasher, and washing machineGraying and fading out of clothingItchy Scalp, dry skin, dry hairHard water spots on dishware and glassware We ULTRA’S SKF have developed a service-oriental infrastructure of specialization with present maintenance support level as follows : Response Time : 06 Hours on an averageDown Time : 24 Hours at maximum on averageStand by support : In case longer breakdownsAMC : Competitive Why to use Water Softeners? Hard water can and will destroy you water using appliances like your water heater, pipes, dishwasher, and washing machine. Hard water will also make your clothing look grey and faded out. Dry skin and dry hair is very common with hard water and can become quite itchy. You will also see hard water spots all over your dishware and glassware, which can be very annoying and bothersome. How Does a Water Softener Work? A water softener uses a medium that serves to exchange "ions" of calcium and magnesium with sodium and potassium. This occurs in four steps : To do the ion replacement, the water in the house runs through a resin bed of small plastic beads or zeolite. The beads are covered with sodium (salt) or potassium ions. As the water flows past the ions, they swap places with the calcium and magnesium ions. Eventually, the beads contain nothing but calcium and magnesium, and after 15/20 days softening stops. It is then time to regenerate the beads or zeoliteTo regenerate, the beads need to regain their sodium or potassium ions by being flooded with a salty, brine solution that is rich in sodium or potassiumOnce completed, the calcium and magnesium, dirt and sediments are flushed from the beads and into the drain in a process called backwashThe final phase rinses the mineral tank with fresh water and loads the brine tank so it's ready for the next cycle for another 15/20 days Water Softener Quick Sizing Chart This chart will help you to choose a water softener size that is right for your needs. You will need to know the number of people in your household and the grains of hardness per gallon in your water. If you need a quick and easy hardness testing kit, go to our Water Test Kit page. Number of People123456780-1024k24k24k32k32k32k40k40k11-2024k24k32k32k40k40k40k48k21-3032k32k40k40k48k48k48k64k31-4040k40k48k48k48k64k64k80k41-5064k64k80k80k80k96k96k110k51-7564k80k80k96k96k110k110k110k76-10080k80k96k96k110k110k110k110k This reference guide is based on every 4th night regeneration. *Additional person compensates for water using appliances. Formula for sizing softeners Capacity = No. of People x Hardness x 70 Gallons x Days Between Regeneration Ex: A family has 4 people with 33 grains per gallon hardness with no iron. 4 + 1(for appliances) x 33 Grains/Gal. x 70 Gallons x 4 Days = 46,200 Grains. In this example, 46,200 grains of capacity is needed on average every 4 days. Because no iron is present, the low salt setting can be used. Select the softener that will provide more than 46,200 grains at the low salt setting. A water softener will remove clear water iron (iron in solution). When removing iron with a softener, compensate the hardness by a factor of 5 grains per gallon for every part per million of iron. Ex: A family has 3 people with 22 grains per gallon hardness and 3 parts per million iron. 3 + 1(for appliances) x 37 Grains/Gal. x 70 Gallons x 2 Days = 20,720 Grains. In this example, 20,720 grains of capacity is needed on average every 2 days. With iron present, the softener should regenerate every other night and use the medium salt setting. Select the softener that will provide more than 21,000 grains at the medium salt setting The Process of Deionization or Ion-exchange In the context of water purification, ion-exchange is a rapid and reversible process in which impurity ions present in the water are replaced by ions released by an ion-exchange resin. The impurity ions are taken up by the resin, which must be periodically regenerated to restore it to the original ionic form. (An ion is an atom or group of atoms with an electric charge. Positively-charged ions are called cations and are usually metals; negatively-charged ions are called anions and are usually non-metals). The following ions are widely found in raw waters : CationsAnionsCalcium (Ca2+)Chloride (Cl-)Magnesium (Mg2+) Bicarbonate (HCO3-)Sodium (Na+)Nitrate (NO3-)Potassium (K+)Carbonate (CO32-)Iron (Fe2+)Sulfate (SO42-) Ion Exchange Resins There are two basic types of resin - cation-exchange and anion-exchange resins. Cation exchange resins will release Hydrogen (H+) ions or other positively charged ions in exchange for impurity cations present in the water. Anion exchange resins will release hydroxyl (OH-) ions or other negatively charged ions in exchange for impurity anions present in the water. The application of ion-exchange to water treatment and purification There are three ways in which ion-exchange technology can be used in water treatment and purification: first, cation-exchange resins alone can be employed to soften water by base exchange; secondly, anion-exchange resins alone can be used for organic scavenging or nitrate removal; and thirdly, combinations of cation-exchange and anion-exchange resins can be used to remove virtually all the ionic impurities present in the feedwater, a process known as deionization. Water deionizers purification process results in water of exceptionally high quality. Deionization For many laboratory and industrial applications, high-purity water which is essentially free from ionic contaminants is required. Water of this quality can be produced by deionization.The two most common types of deionization are: 5. Two-bed deionization6. Mixed-bed deionization Two-bed deionization The two-bed deionizer consists of two vessels - one containing a cation-exchange resin in the hydrogen (H+) form and the other containing an anion resin in the hydroxyl (OH-) form. Water flows through the cation column, whereupon all the cations are exchanged for hydrogen ions.To keep the water electrically balanced, for every monovalent cation, e.g. Na+, one hydrogen ion is exchanged and for every divalent cation, e.g. Ca2+, or Mg2+, two hydrogen ions are exchanged. The same principle applies when considering anion-exchange. The decationised water then flows through the anion column. This time, all the negatively charged ions are exchanged for hydroxide ions which then combine with the hydrogen ions to form water (H2O). Mixed-bed deionization In mixed-bed deionizers the cation-exchange and anion-exchange resins are intimately mixed and contained in a single pressure vessel. The thorough mixture of cation-exchangers and anion-exchangers in a single column makes a mixed-bed deionizer equivalent to a lengthy series of two-bed plants. As a result, the water quality obtained from a mixed-bed deionizer is appreciably higher than that produced by a two-bed plant. Although more efficient in purifying the incoming feedwater, mixed-bed plants are more sensitive to impurities in the water supply and involve a more complicated regeneration process. Mixed-bed deionizers are normally used to ‘polish' the water to higher levels of purity after it has been initially treated by either a two-bed deionizer or a reverse osmosis unit. Electrodeionization EDI Electrodeionization Systems remove ions from aqueous streams, typically in conjunction with reverse osmosis (RO) and other purification devices. Our high-quality deionization modules continually produce ultrapure water up to 18.2MW/cm. EDI may be run continuously or intermittently STAGE 5 & 6 - DEIONIZATION Fundamentals of Deionization by Ion Exchange Deionization is a method used most often by laboratories to produce purified water on demand. All naturally-occurring water contains dissolved mineral salts. In solution, salts separate into positively-charged cations and negatively-charged anions. Deionization can reduce the amounts of these ions to very low levels through the process of ion exchange. Cations are removed by cation exchange resin. It replaces sodium, calcium, magnesium, and other cations with hydrogen ions (H+). This exchange produces acids which must be removed or neutralized by anion exchange resin. Two general types of anion resin are used for deionization: weak base resin and strong base resin. Weak base resin adsorbs strong acids, while strong base resin exchanges chloride, sulfate and alkaline anions for hydroxide ions (OH-). The hydrogen ions from the cation exchange process combine with the hydroxide ions from the anion exchange process to form water (HOH or H2O). Because the deionization process is so effective, the water quality is usually measured by the water's resistance to electric current (in OHM-cm). Deionized water quality depends on a variety of factors, including raw water composition, ion exchange types and quantities, and the number of resin tanks in the system. Two-bed deionizers use separate tanks, one containing cation resin, the other containing anion resin. A two-bed weak vase deionizer typically produces water with electrical resistance of about 50 kOHM-cm. A two-bed strong base deionizer typically produces water with electrical resistance of about 200 kOHM-cm. In a mixed bed deionizer, cation and anion resins are thoroughly mixed in a single tank. The mixed resins act like a series of alternating cation and anion exchange tanks to produce very high quality water. A mixed-bed deionizer typically produces water with greater than 10 megOHM-cm resistance which is equivalent to less than 0.05 mg/L of sodium chloride. The resins need regeneration when they no longer produce the desired water quality. In the case of a two-bed deionizer, the cation tank is backwashed for 5 to 10 minutes, then washed with a solution of acid. Then the anion tank is backwashed and washed with a solution of caustic. After rinsing the residual chemicals from each tank, water flows through both tanks to drain until the water reaches the desired quality. In a mixed-bed deionizer, the resins have to be separated before regeneration. After regeneration and rinsing, they have to be remixed, using air, before returning to service. Although the process is fairly simple in concept, its application is complicated by different variables.

Softener Plant

Get Price Quote

We are offering Softener Plant. Softener plant remove the hardness from the water.

Magnetic Water Conditioners

Get Price Quote

We carry out the quality examinations only under the vigil supervision of the quality auditors. Owing to our excellent in-house amenities in Gaya(India), we deliver huge assortment of products to the customers.

Water Softners

Get Price Quote

The Water Softeners are used for softening the hard water into soft water. The Industrial Water Softeners offered by us are highly improved in terms of quality and performance. The Water Softening Plant can treat toughest hard water and make it suitable for usage. Besides a renowned Manufacturer, we are among the leading Suppliers of Water Softeners in India. What makes water "hard"? Groundwater dissolves rocks and minerals releasing calcium and magnesium ions that cause water to be hard. These dissolved ions give hard water its characteristics. Problems caused by hard water Hard water interferes with all types of cleaning tasks. Cleaning problems arise when the cleaning agents do not fully remove dirt and grime. Over time, clothes washed in hard water may look dingy and feel harsh and scratchy. White clothing continually washed in hard water will gradually show a grayish tinge. Dishes and glassware washed in dishwashers using hard water may be spotted when dry. Hard water causes films on glass shower doors, walls and bathtubs. Hair washed in hard water may feel sticky and look dull. Regular soaps combine with dissolved calcium and magnesium to form soap curds or soap scum. Soap scum is difficult to remove from sinks and appliances. Household appliance performance may be affected by hard water use. When heated, calcium carbonate and magnesium carbonate are removed from the water and produce a scale buildup in the hot water heater. A large scale buildup slows the heating process and requires more energy to heat water. Water heaters with large accumulations of mineral buildup will have shorter life spans. Scale deposits also corrode and plug plumbing fixtures and accumulate in other appliances affecting their performance. Water testing Before buying any water treatment equipment, you should know what impurities are found in the water supply. Types and amounts of impurities in your water can be determined by a certified laboratory. The results of the water test will help determine if softening is needed. The water testing may reveal if other water treatment is required. If you obtain water from a private water supply, water testing is your responsibility. Water testing should be done on a regular basis. If a problem is suspected, test more often. Community water supplies are monitored and treated to protect users from health threatening water impurities. Ask your supplier for a copy of the latest water test results. Hard water is considered a nuisance water problem. Hardness removal is not a necessity to protect your health. Water softening is popular because most people prefer softened water for bathing, cleaning and washing. Types of water softening equipment available Water softeners are classified in five different categories: Manual : There are several types of manual softeners. The operator opens and closes valves to control the frequency, rate and time length of backflushing or recharging. Semi-Automatic : The operator initiates only the recharging cycle. A button is pushed when the softener needs recharging and the unit will control and complete the recharging process. Automatic : The automatic softener usually is equipped with a timer that automatically initiates the recharging cycle and every step in the process. The operator needs only to set the timer and add salt when needed. It is the most popular type of softener used.

Industrial Water Softener

Get Price Quote

Industrial Water Softener, RO Water Purifier, Water Softener

domestic water softener

Get Price Quote

domestic water softener, RO System For Pharmacy, Fire Hose Reel

Water Conditioning System

Get Price Quote

Water Conditioning System, Steam Bath System, chiller system, Water Boiler

Water Softening Plant

Get Price Quote

Leveraging on our innovative technology and modern machineries, we strive to retain the top status in the industry. We as a Manufacturer and Supplier of Water Softening Plant serve water treatment needs. We make Water Softening Plant available in a range of capacity variations as per the customers’ requirement. Water Softener Plant works based on Softeners which discard all the impurities and purify the water. The plant is also equipped with a special membrane separator to de-concentrate a number of mechanically or chemically emulsified solutions.Highlights : Equipped with advanced machines Easy to install Low maintenance needs Suitable for cleaning all types of emulsified solutions

Softener Water Plants

Get Price Quote

We are an eminent and leading trader of Softener Water Plants

Water Softener Plant

Get Price Quote

The company is a credible Manufacturer and Supplier of highly efficient Water Softener Plant. Our Water Softener Plant is enabled with the high capacity water softeners that are highly effective in removing impurities from water. The purifiers in our Water Softener Plant are also provided with a special membrane separator, which is suitably affixed to de-concentrate a wide variety of chemical or physical impurities. Clients can avail our Water Softener Plant at much discounted market prices. Highlights Easy to installSuitable for cleaning all types of emulsified solutionsEquipped with advanced componentsLess maintenance

Water Softener Plant

Get Price Quote

We are a well-known Manufacturer and Supplier of high capacity Water Softener Plant. These Water Softener Plants are available as per the customized requirements of the clients in mid size and high capacity variants as well. The Water Softener Plant is equipped with the high capacity water softeners which work effectively by removing the other impurities present in the water. We manufacture superior grade Water Softeners and Purifiers which effectively discard all the impurities and make the water pure. Further, the purifiers at our Water Softener Plant are also provided with a special membrane separator which is suitably affixed to de-concentrate a wide variety of chemically or mechanically emulsified solutions. Highlights : Equipped with advanced machinesEasy to installLow maintenance needsSuitable for cleaning all types of emulsified solutions

Water Softening Plant

Get Price Quote

Water Softening Plant, Water Filtration Plant, Water Purification Plant

Water Softener

Get Price Quote

Water Softener, water filtration, Shower Filter, ro purifier system

water softner plant

Get Price Quote

water softner plant, Water Cooler, membrane, Air Conditioning Services

Water Softener

Get Price Quote

Water Softener, Domestic RO Purifier, domestic water softener

Water Softening Plant

Get Price Quote

Water Softening Plant, Boiler Water Treatment Chemicals

Water Softener

Get Price Quote

Water Softener

aquarium

Get Price Quote

aquarium, Marine Aquarium, saltwater aquarium, reef aquarium