Wire Rod Rolling Mill Plant

Voltage : 380V, 440V

Automation Grade : Automatic

Structure Rolling Mill Plant

Type : Rolling Mill Plant

Weight : 1000-2000kg

Voltage : 380V

Automatic Grade : Automatic

Driven Type : Electric

...more

Steel Forgings

We are one of the prominent Manufacturers, Exporters & Suppliers of Steel Forgings in Mandi Gobindgarh. Offering a wide range of Steel Forgings such as Couplings, Forged Shafts, Gear Blanks, Pinion Gears, Reduction Gears and Rolling Mill Rolls, the company caters to a worldwide demand for these products. The Steel Forgings are manufactured using the best grade steel and other raw materials. Highlights Of Steel Forgings : Corrosion resistantFacilities for normalizing, annealing & heat treatmentSingle piece of 50 Kg to 6 tonsLength up to 8 meters (10 meters on special request.)

...more

Slitter Steel Rolling Mill Plant

Type : Rolling Mill Plant

Weight : 1000-2000kg

Voltage : 380V

Automatic Grade : Automatic

Driven Type : Electric

...more

Single Beam Eot Cranes

We have emerged as a major Manufacturer, Exporter & Supplier of Single Beam EOT Cranes in Mandi Gobindgarh. The Hoist Single Beam EOT Cranes are widely known for the ample space that they provide in the various material handling applications. Compact and highly efficient, the Single Beam EOT Cranes work admirably in the small spaces as well and can minimize the costs of building modification. The Single Beam EOT Cranes have a simple girder and can be individually fitted to the spaces that are available. Features Of Single Beam EOT Cranes : Favorable dimensions result in optimal hook positionUse of various fixing arrangementsCan be designed to fit the available spaceCustomized forms availableCompact dimensionsLight weightEasy to operate and maintainModular design with direct fits between components

...more

single beam eot crane

Hoist provide space for materials handling even when production units or warehouses are comparatively small and low. To minimize the capital costs for modifications to bulidings to provide extra space, we utilize the minimum of space for our crane systems. Using various fixing arrangements the single girder Hoist cranes can be fitted individually to the existing space available. Favorable dimensions result in the optimal highest hook position. Using a comprehensive range of fixing arrangements the Hoist cranes can be designed to fit the available space. All we need for the planning stage of the crane system are the clear dimensions of the building. We will then design the Hoist crane individually for you. Design: Compact dimensions, low weight, easy to operate and easy to maintain, modular design with direct fits between components.

...more

Rolling Mill Rotary Shear

Driven Type : Electric

Automation Grade : Fully Automatic with Pneumatic Controls

Type : Fixed and Swiveling Type

Features : Capable to Cut Hot Ends During Rolling, High Quality Circular Blades with Angular Edge

...more

Rolling Mill Rolls

Material : Metal

Shape : Round

Thickness : 15-20mm

Application : Industrial Use

Color : Shiny SIlver

Feature : Heat Resistance, Robust Construction

...more

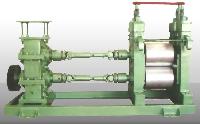

Rolling Mill Plant

Leveraging on the support of competent workforce, we are able to manufacture, supply and export optimum quality Rolling Mill Plant. Our experts always keep an eye on the evolving trends of the market and further, by making use of best grade raw material, manufacture the offered rolling mill plants accordingly. In addition to this, they keep in mind the specifications ordered by patrons while manufacturing these rolling mill plants. Attributes: Trouble free operation Easy to maintaining Resistance against wear

...more

Rolling Mill Pinch Roll

Material : Available in steel fabricated body.

Feature : Long Life, Optimum Performance

Rolling Mill Gears

product details : tested material dp system in teeth cutting 10 dp to 1.5 dp desired helix angle & module system

Material : Metal

Shape : Round

Thickness : 50-75mm

Application : Mill Use

...more

Rolling Mill Gear Coupling

Speciality : High Strength

Material : Metal

Color : Grey

Finishing : Polished

Head Shape : Round

Corrosion Resistance : Yes

...more

Rolling Mill Flywheel

mounting: it should be mounted on en-8 forged steel shaft fitted with double row spherical roller bearing & brackets & pedestals.

Application : Industrial

Color : Grey

Type : C.I. Casted / Steel Casted/ Steel Fabricated Statically & Dynamically Balanced.

Weight : 2 Ton- 17 Ton

...more

Rolling Mill Bearing

In metalworking, rolling is a metal forming process in which metal stock is passed through a pair of rolls. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is termed as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is termed as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process and cold rolling processes the most tonnage out of all cold working processes. AFW has been providing complete solutions for the design, manufacture, and supervision of erection and commissioning of Rebar, Wire rod, and section rolling mills for more then 60 years. Our team of highly qualified and experienced design engineers are instrumental in providing value added solutions for the hot rolling mill industry.

...more

Reduction Gears

Material : Metal

Application : Industrial Use

Weight : 20-30kg

Color : Silver

Finishing : Polished

...more

Reduction Gear Boxes

We are a well-known manufacturer, exporter & supplier of reduction gearbox in mandi gobindgarh. The reduction gearbox, offered by us, can be availed in various sizes and it conforms to the industrial norms. The reduction gearbox is fabricated using the best grade raw materials and the use of the latest techniques in manufacturing makes the gearbox highly efficient. features of reduction gearbox : accurately machined, totally enclosed and oil tight bodiessufficient lubrication systemdust proofbodies made from steel plates to cover risk of breakagereduction gears made in single, double and multi stages with double helical, single helical and spur gearsgears made from high quality steel (en-9, en-19, or en-24) as per customer requirementsimported double roller (self aligned) bearings usedoil seals provided outside the bearings to protect from oil leakagefull speed trial is carried out to verify smooth operations

...more

Reduction Gear Box

Product Details : The Bodies of the reduction gears are accurately machined, totally enclosed, oil tight, having a sufficient lubrication system and are dust proof. The bodies are made from steel plates to cover the risk of any breakage. The reduction gears are made in single, double and multi stages with double helical, single helical and spur gears, as per order. The gears of the reduction gears are made from high quality steel. ( EN-9, EN-19, or EN-24 ) as per customer requirement. Imported double roller (self aligned) bearings are used and the oil seals are provided outside the bearing to protect the oil leakage. The reduction gears are made of various sizes to meet the customer's requirements.

Application : Industrial

Specialities : Rust Proof

Material : aSteel

Color : Grey

Finishing : Polished

...more

Reduction Cum Pinion Gearbox

Usage : Industrial

Specialities : Rust Proof, High Performance

Voltage : 380V

Finishing : Powder Coated

Driven Type : Electric

Corrosion Resistance : Yes

...more

Plate Shearing Machine

Weight : 100-1000kg

Voltage : 220V

Rated Power : 3-6kw, 6-9kw

Automatic Grade : Automatic

Driven Type : Elecric

...more

Plate Hot Rolling Mill Plant

Application : Industrial

Voltage : 380V

Power : 9-12kw

Driven Type : Electric

Automation Grade : Automatic

...more

Pinion Gears

Material : Metal

Shape : Round

Application : Industrial

Color : Silver

Finishing : Polished

...more

Pinch Rolls

The company has established itself as a leading Manufacturer, Exporter & Supplier of Pinch Rolls in Mandi Gobindgarh. The Pinch Rolls are available in numerous sizes and are fabricated using the superior quality materials. The Pinch Rolls come with a varied pinching capacity. The company offers the best Pinch Rolls to the clients. Highlights Of Pinch Rolls : Pinching Capacity : 8 mm to 25 mm (HOT)Size Range : 150 mm to 400 PCDAvailable in steel fabricated bodyGears from forged tested EN-9 Steel

...more

Mill Stands

4HI MILL STANDS Providing you the best range of 4hi rolling mill stand with effective & timely delivery.

Brand Name : AVTAR

Country of Origin : India

...more

Housingless Stand

Our Company manufactures housingless stands of the horizontal and vertical types. Compared to traditional design such stands have increased stiffness. It allows to increase quality of rolled product. As a result of installation of two lines of vertical stands 320 after a linear mill rolled product The connection and disconnection of the spindles and all the fluid utilities are fully automatic and therefore the stands can be interchanged very quickly. Different versions including horizontal, vertical, convertible and drop-in joker are in operation, allowing rapid adaptation to the variety of the rolled products needed to fulfil stringent market demands. Line flexibility allows rolling with low-temperature, high-alloy, wide forming passes, etc. Technical Specification : Steel Fabricated, Steel Casted and graded C.I Casting Housing. Centre roll fix, Fibre type stands Gun metal Cottar type Stands. Bearing type stands for higher speeds. Ranging from 150 mm PCD to 900 MM PCD. Salient Features : Simple and compact design ensures quick roll changing. Independent screw up/down mechanism on drive and non-drive ends. Minimum Maintenance.

...moreOpening Hours