Worm Gears

Worm-and-gear sets are a simple and compact way to achieve a high torque, low speed gear ratio. For example, helical gears are normally limited to gear ratios of less than 10:1 while worm-and-gear sets vary from 10:1 to 500:1

...more

wire rod rolling mill

We manufacture and supply Wire Rod Rolling Mill Plant to produce high quality wire coils from 6 mm to 12 mm production capacity up to 200000 ton Per Year. The calculation varies according to the grade of material being rolled.

...more

wire rod mills

Wire Rod Mills We manufacture and supply Wire Rod Rolling Mill Plant to produce high quality wire coils from 6 mm to 12 mm production capacity up to 200000 ton Per Year. The calculation varies according to the grade of material being rolled.

...more

Universal Shearing Machine

An Alligator Shear, historically known as a Lever Shear, is a metal-cutting shear with a hinged jaw, powered by a flywheel or a hydraulic cylinder. The jaw size can range from 4 to 36 in (100 to 910 mm) long. They are generally used to cut steel members, such as rebar, pipe, angle iron or I-beams. With an automatic cutting cycle and complete with fork truck lifting pockets the new alligator shear weighs much less than the traditional shears and has a more material cutting capacity of upto70mm mild steel bar.

...more

TMT Quenching Box

We provide complete solutions for TMT Plant. for superior mechanical properties in strength, weld ability, ductility, and bendability, meeting International quality standards.. Our TMT plant supports Size ranges from 8mm to 40mm and speeds up to 25 meters per second.

...more

tmt box

We provide complete solutions for TMT Plant. for superior mechanical properties in strength, weld ability, ductility, and bendability, meeting International quality standards.. Our TMT plant supports Size ranges from 8mm to 40mm and speeds up to 25 meters per second.After the hot rolled bar leaves the finishing mill stand , It is rapidly quenched by a water spray system hardening the surface of the bar to an optimized depth optimized through formation of martensitic rim while the core remains hot and austenitic.

...more

Tail breaker

Tail breaker is installed after the flying shear & before the cooling bed to reduce the velocity of TMT bars. It runs through ac & dc variable drives. The rolls are separated through pneumatic cylinder. It consists of steel fabricated body, Pneumatic cylinder, top and bottom arms and rolls.

...more

Straightening Machine

Straightening Machines are use to straighten Section Like Iron angle, Channels, Beams, Flats, Hex, Square and any profile Sections like Z Section, F7 Section. Section Straightening MachinesDouble supported Straightening Machine. All Types of models are design on the basis of Section Size and accordingly we design centre distance of the Rolls in between..We have manufactured Machine for Iron Angle up to 250 x 250 x 35 mm and for I Beam up to 600 x 210 mm so far.The roller section straightening machine is most suitable for straightening of any rolled, drawn or extruded ferrous and non-ferrous in cold condition.. All straightening rolls (Top and Bottom) are mounted on cantilever type spindle. This arrangement is most suitable where quick change of rolls is required. Bottom rolls are driven by a distribution gear train. The directions of bottom rolls are clockwise/ anticlockwise depending upon of material. The top rolls for applying straightening pressure on material. These are having up-down and axial adjustment from front by hand wheels or optional motorized system.

...more

Sprocket Gears

Fabricated using high quality raw material and are designed with utmost precision and attention. Our sprockets help in avoiding early elongation of chain minimizing break downs and reducing the power consumption, resulting in high productivity.

Type : Simplex Sprockets, Duplex Sprockets, Triplex Sprockets.

...more

Speed Increaser

Speed Increaser improves machine productivity. They are generally installed in bar mill in between intermitted mill stands to increase output speed of the rolled product and offer greater rigidity and accuracy.

...more

Snap Shears

Snap Shears We supply excellent quality pneumatic snap shears that are known for their efficiency & durability. These are used for cutting the material while transfer or miss roll in intermediate mill, complete with cylinders and solenoid valves. These snap shears are suitable for various industries in their production processes with different sizes.

...more

Section Straightening Machine

The roller section straightening machine is most suitable for straightening of any rolled, drawn or extruded ferrous and non-ferrous in cold condition.. All straightening rolls (Top and Bottom) are mounted on cantilever type spindle. This arrangement is most suitable where quick change of rolls is required. Bottom rolls are driven by a distribution gear train. The directions of bottom rolls are clockwise anticlockwise depending upon of material. The top rolls for applying straightening pressure on material. These are having up-down and axial adjustment from front by hand wheels or optional motorized system.

...more

section mill

We manufacture machinery for producing structure steel like Angle, Beam, Channels, Flat, and Girders etc. of various size range from 25 mm to 600 mm structure production capacity up to half million ton.

...more

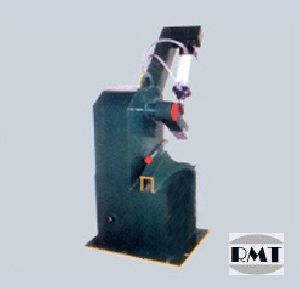

Scrap Shearing Machine

Scrap Shearing machines are used for cutting re-roll able scrape plates, rails, beams, channels, rounds, angles, squares, etc. in cold condition and the machines are usually heavy duty. RMT manufactures scrap shearing machines with capacity of 18 mm to maximum of 75 mm (cold metal).

...more

Rotary Shears

Used for automatic cutting of split hot ends (front and rear). We offer fix and swivel base type of Rotary Shearing Machines. It could be further customized on clients requirement.

...more

Rotary Shearing Machines

Used for automatic cutting of split hot ends (front and rear). We offer fix and swivel base type of Rotary Shearing Machines. It could be further customized on clients requirement specification

...more

Rolling Mill Plant

Roughing mill with horizontal-vertical stands of housingless or cantilever(Conventional) design,Finishing mill with housingless convertible horizontal-vertical stands and quick-change equipment,Finishing facilities with cold shear, bundle forming equipment and wire tying machines.

...more

Roller Guide Box

Roller guide boxes are employed in a continuous rolling operation at input side. Simple design allows easy installation with smooth operation in different rolling conditions. It is made out of non magnetic Stainless Steel. It has low power consumption.

...more

Reduction Gear Boxes

Reduction Gear Box is used to reduce an input speed to a slower output speed and more output torque. It is a wheel work consisting of a connected set of rotating gears by which power is transmitted or motion or torque is changed. We manufacture single stage, double stage or multistage gear boxes. Qualities Gear boxes designed as per ASTM/DIN/ Indian standards. Designed to dampen vibrations. Work efficiently at peak loads. Single, double & multi stage. Desired gear ratio. Gears in DP system and module. Forced, Splash & Spray Lubrication. Fabrication Steel fabricated body and housing. Double oil seals. Spherical Roller Bearing. Heat dissipation window. Fully machined Shaft. Hardened & grinded gear for smooth run(forged EN-9, EN-19, EN-24 steel). Size range of 150mm PCD up to 750mm PCD. Speed of 50 RPM to 1500 RPM. All Shafts of material forged class-IV. Branded Heavy Duty Antifriction Spherical Roller Bearings are installed after thorough calculation. Double Oil Seals complete with Internal & External Pipeline for lubrication of Gears & Bearings is provided. Inspection window at various levels is provided for proper viewing of gears inside the gear box. Flow indicator, temperature indicator and proper interlocking with mill is done. Vent Pipes are provided for release of heat and oil from inside the Gear Box. 72 Hour Non-stop trial of gear box is done on various speeds before dispatch. Vibration, voice and lapping levels are thoroughly checked on trial before dispatch.

...more

Rebar Mills

Used for producing rebars from ingots or billets with size of finished rebar varying from 8 mm to 32 mm . Annual production upto 300,000(three thousand metric ton per year) can be achieved using slit rolling technology.

...more

Pinion Gear Box

We are offering pinion gear box. specifications steel fabricated body and accurately machined, totally enclosed, oil tight, having a sufficient lubrication system and dust proof. Gears made of en-9, en-19 or en-24 according to the requirement. The gears are made in d.p. And module formula with single or double helical teeth. 3 hi or 2 hi as per order suitable for 6� to 20� pcd mills.

...more

Pinion Gears

Steel Fabricated body and accurately machined, totally enclosed, oil tight, having a sufficient lubrication system and dust proof. Gears made of En-9, En-19 or En-24 according to the requirement. The gears are made in D.P. and module formula with single or double helical teeth. 3 hi or 2 hi as per order suitable for 6″ to 20″ PCD mills. Imported double roller (self aligned) bearings are used and the oil seals are provided with the bearings to protect the oil leakage. Pinion Gear box is tested at full capacity to ensure smooth operation before delivering the product to the customer.

...more

Pinch Roll

PINCH ROLLS comprise of Two rolls used to accelerate the speed of the hot produce in the rolling mill plant. This machine is mostly used in bar mill.

...more

Mechanical Pusher

Pushers are used in continuous type furnace. We design, manufacture and supply hydraulically operated, mechanically operated (screw type) and pneumatically operated pushers in steel rolling mill where the continuous type furnace are being used.

...moreBe first to Rate

Rate ThisOpening Hours