Special Purpose Machines

Certification : CE Certified

Weight : 100-1000kg

Voltage : 220V

Automation : Fully Automatic

...more

sheet moulding compound

Sheet molding compound (SMC) is a process as well as reinforced composite material. The composite is a �ready to mold� glass and other fibre reinforced polyester resin material mainly used in compression molding. The compound is produce in rolls and zigzag winding shapes, SMC compound is manufactured by uniform distribution of chopped strand glass or other fibres in required proportion by weight over moving carrier film having layer of resin compound from upper and lower doctor box.

...more

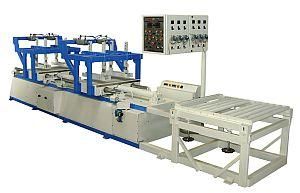

Sheet Molding Compound Machine

Sheet molding compound (SMC Machine) is a process as well as reinforced composite material. The composite is a “ready to mould” glass and other fibre reinforced polyester resin material mainly used in compression moulding. The compound is produce in rolls and zigzag winding shapes, SMC compound is manufactured by uniform distribution of chopped strand glass or other fibres in required proportion by weight over moving carrier film having layer of resin compound from upper and lower doctor box.Mix matrix is then impregnated by passing through upper and lower set of rollers with control pressure and after final impregnation compound sheet is collected at the winder either by roll winding or zig-zeg winding for further storage and use.Compound sheet can be produce with following variables, Compound sheet width and thickness Compound sheet unit area weight Percentage of glass / other reinforcement in compound sheet With different strand length as per product requirement Composite SMC has many important areas of applications as under,Automotive parts, high-strength electrical parts, Switchgear body, Meter Box, Junction Box, Panel Enclosure, Motors Shrouds, Generator Enclosures, Panel Tank Components, Railway Coach Components, Military & Aerospace, Transportation, Safety, Medical, Electrical, Oil & Gas, Alternative Energy, Marine, and various structural components.SMC Machine Features: Precision tubular machine structure with epoxy primer and PU paint. Precision machine components with required protective coating. Life lubricated gear reduction drives. PLC, HMI, AC Drives for machine operation and control.

...more

Section Cutter

The Company is Well Reckoned as One of the Key Manufacturers and Suppliers of High Quality Section Cutter. Pultrusion Machine Section Cutter is Installed Between the Pultrusion Machine & Roller Table. Use of Finest Quality Steel Like, Channel, Angle or Pipe Ensures the High Performance of Our Automatic Section Cutter. Pultrusion Machine Section Cutter Provided By Us is Ideal to Cut the Pultruded Profiles from the Pultrusion Machines At Predefined Lengths. We Offer Pultrusion Machine Section Cutter Within the Specified Time Frame At Reasonable Prices. fabricated Form Structural Steel Like, Channel, Angle or Pipe working On Principal of Flying Cut-off Saw electrodeposited Diamond Cut-off Disc of Ø 300 / 400 Mm operating By 1.5 Kw / 2.0 H.p Motor section Clamping, Cutter Troll Movement & Cut-off Blade Movement By Pneumatics auto / Manual Operating Mode Using Plc compressed Air Require: 2.0 – 3.0 Cfm At 3.5 – 5.0 Kg/cm² Pressure electric Requirement: 1.5 Kw.

...more

Section Conveyor Roller Table

Roving Guide Stand

Length : 2000mm

Width : 1000-1600mm

Height : 2100mm

Material : Structural Steel

Finishing : Coated

Color : White

...more

Resin Injection System

Length : 600mm

Width : 600mm

Height : 1000mm

Material : M.S. Sheet

Use : Pressure Resin Injection System type of Pultrusion Process / Mold

...more

Resin bath

Pultrusion Mold

Precision machined, mirror finished / polishing and hard chrome plated moldManufactured using suitable die steelNormally 800 mm or 1000 mm long

...more

Pultrusion Machinery

We are offering pultrusion machinery. This machine is suitable for producing g.r.p. (glass reinforced plastic) sections in different shapes & sizes like angle sections, ‘c’ channels, hollow rectangular and circular-tube sections, solid rods etc. Direct acting vertical hydraulic clamping is more preferable to work with thick wall flat and wider profiles rather than thin wall hollow profiles. Single platen vertical hydraulic clamping with wider area allows larger width profiles and single profile option or multiple cavity similar profiles within same clamping area. Double platen vertical hydraulic clamping allows different profiles width and height clamping in each puller as well as both platen can be engaged for one wider profile within specified limit of clamping area.

...more

Pultrusion Machine -pag-0002

We are Offering Composite Pultrusion Machine.

pultrusion machines

We are offering pultrusion machine. This machine is suitable for producing g.r.p. (glass reinforced plastic) sections in different shapes & sizes like angle sections, �c� channels, hollow rectangular and circular-tube sections, solid rods etc. We also manufacturing accessories for pultrusion machines like, automatic section cutter, mat slitter, creel (roving) stand, resin bath, pressure vessel for resin impregnation system.

...more

Pultrusion Die

Pultrusion Mould manufactured from selective alloy steel with precision machining, grinding, polishing and hard chrome plating in useful surfaces followed by accurate assembly and inspection for assured productive performance and easy handling,We can supply complex pultrusion dies as well as hollow pultrusion dies with mandrills and performers.

Material : Steel

Application : Decorative Building

...more

Preform Guide Stand

Length : 1000mm

Width : 1000mm

Height : 300mm

Material : Structural Steel

Finishing : Coated

...more

pultrusion machinery (Reciprocating Hydraulic, Pneumatic Actuating Mechanical Gripper Type)

This machine is suitable for producing G.R.P. (Glass Reinforced Plastic) Sections in different shapes & sizes like Angle sections, ‘C’ Channels, Hollow Rectangular and Circular-Tube Sections, Solid Rods etc., Due to its specific angular lever clamping mechanism in dynamic action this is more preferable for working with thin wall hollow profiles compare to direct acting hydraulic clamping, As well as more flexible for easy production adjustment while using multiple profiles with different height

Type : Pneumatic Gripper

Thickness : 0-10 Mm

Finishing : Polished

Width : 1000mm

Bore Size : 20mm, 25mm

Temperature : 30-60 Deg C

...more

Mat Slitter

We Provide Superior Quality Mat Slitter that is Manufactured from the Premium Structural Steel Like, Channel, Angle or Pipe. Glass Mat Slitter Offered By Us is Perfect for the Mat Roll Up to Ø 400 Mm X 1600 Mm. Precisely Designed, Our Glass Mat Slitter is of High Performance and Low Maintenance. We Offer Glass Mat Slitter At Competitive Prices At a Very Brisk Pace. We are Well Reckoned as One of the Distinguished Roll Mat Slitter Manufacturers and Exporters Based in India. fabricated Form Structural Steel Like, Channel, Angle or Pipe slitting Width / Blade Position Adjustment By Manual mat Roll Mounting Spindle Movement By Suitable Geared Reduction Drive & Inverter Drive for Achieving required Spindle Speed electric Requirement: 0.75 Kw.

...more

Mat Roll Stand

hydraulic clamping pultrusion machine

This machine is suitable for producing G.R.P. (Glass Reinforced Plastic) Sections in different shapes & sizes like Angle sections, ‘C’ Channels, Hollow Rectangular and Circular-Tube Sections, Solid Rods etc.Direct acting vertical hydraulic clamping is more preferable to work with thick wall flat and wider profiles rather than thin wall hollow profiles.Single platen vertical hydraulic clamping with wider area allows larger width profiles and single profile option or multiple cavity similar profiles within same clamping area.Double platen vertical hydraulic clamping allows different profiles width and height clamping in each puller as well as both platen can be engaged for one wider profile within specified limit of clamping area.

...more

Pultrusion Machine

We offer pultrusion machine.

Fibreglass Pultrusion

This machine is suitable for producing G.R.P. (Glass Reinforced Plastic) Sections in different shapes & sizes like Angle sections, ‘C’ Channels, Hollow Rectangular and Circular-Tube Sections, Solid Rods etc.

Type : Pultrusion Machine

Material : Mild Steel

Application : Industrial

...more

Glass Mat Slitter

Suitable for Mat Roll up to Ø 400 mm X 1600 mm Length Slitting width / Blade position adjustment by manual Mat Roll mounting spindle movement by suitable geared reduction drive & inverter drive for achieving required spindle speed Electric requirement: 0.75 kW. Fabricated form structural steel like, channel, angle or pipe

...more

Frp Pultrusion Machine

technical specifications:- pulling capacity 1000 kgf to 4000 kgf. Pulling speed 0.02 metermin. To 4.0 metermin. Die clamping bed 800mm [w] x 1000mm [l] puller width 100mm - 300mm gripping by puller pads. Pulling action by mechanical geared power transmission clamping force by pneumatics cylinders heating zone 4 nos. Electrical power required 2.0 to 3.5 kw. Heating requirement (depending up on size of mould) compressed air required approx- 4-5 cfm, & 5 -6 kgcm² pressure. Accessories glass roving (creel) stands, roving guides, perform guides, resin impregnation bath, resin pressure injection system, glass mat roll feeding station, automatic section cutter, section conveying roller table, glass mat slitter & pultrusion mold, approximately overall dimensions length width height 2500 – 3000mm 600 – 1100mm 2100m

Type : Pultrusion Machine

Material : Mild Steel

Application : Industrial

...more

Creel Stand / Glass Roving Stand

Fabricated form structural steel like, channel, angle or pipe and sheet metal Supplied in one, two or three modules each having capacity of storing about 100 creels Each individual roving are guided through ceramic guide bushes Approximate overall dimension:

Height : 2200mm

...more

creel stand

Finishing : Coated

Material : Structural Steel

Height : 2200mm

...moreOpening Hours