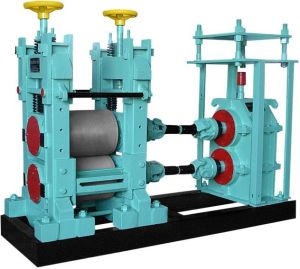

Straightening Machine

The Section Straightening Machines are used to Straighten Rolled Steel Sections like Angle, Channels, Rounds, Beams etc. Straightening Rolls are made according to section from Adamite material. The company has supplied these machines to various reputed concern. leading suppliers of straightening machines exporters, straightening machine manufacturer, section straightening machine suppliers, straightening flattening machine exporter. Straightening machine made up of steel fabricated M. S. plates of amply thickness with outer lining of same plates to strengthen the body will carry gears of En -19 steel to run the rolls. The machine will contain sufficient rolls of Adamite containing anti friction roller bearings.

...more

Reduction Gears

The Bodies of the reduction gears are accurately machined, totally enclosed, oil tight, having a sufficient lubrication system and are dust proof. The bodies are made from steel plates to cover the risk of any breakage. The reduction gears are made in single, double and multi stages with double halical, single helical and spur gears, as per order. The gears of the reduction gears are made from high quality steel. ( En-9, En-19, or En-24) as per customer requirements. Imported double roller (self aligned) bearings are used and the oil seals are provided outside the bearings to protect the oil leakage. The reduction gears are made of various size to meet the customer’s requirements. All parts are checked during and after manufacturing, and a full speed trial is carried out to verify smooth operations.

...more

Pinion Gears

The bodies of the Pinion Gear Box are accurately machined, totally enclosed, oil tight, having a sufficient lubrication system and dust proof. The bodies are made from steel plates to cover the risk of any breakage. The gears of Pinion gear boxes are made of En-9, En-19, or En-24, forged steel as per customer’s requirements. The gears are made in D.P. and module formula with single or double helical teeth. The Pinion gear boxes are made 3 hi or 2 hi as per order suitable for 6″ to 36″ PCD mills. Imported double roller (self aligned) bearings imported are used and the oil seals are provided outside the bearings to protect the oil leakage. All Parts are checked during and after manufacturing, and a full speed trial is carried out to verify smooth operation.

...more

Pinch Roll

Specification: * Pinching capacity 8 mm to 25 mm (HOT) * Size Range 150 mm to 400 mm PCD. Salient Features: * Available in steel fabricated body. * Gears from forged tested En-9 Steel.

...more

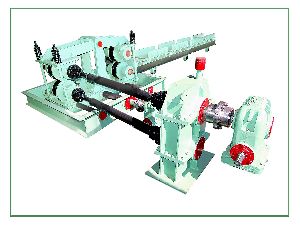

FURNACE CHARGING PUSHER

With the support of our proficient workforce, we are regarded as one of the most prominent manufacturers, suppliers and exporters of Furnace Charging Pusher Machine. In order to meet the rising needs of the clients, we are manufacturing extensive array of charging pusher machines for our diverse clients. Offered Furnace Charging Pusher Machine finds wide usage in rolling mills and other areas. These pusher machines are highly accredited in the market for its distinctive features such as high durability, high resistance and low maintenance.

...more

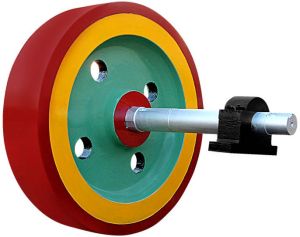

Fly Wheel

C.I. Casted / Steel Casted / Steel Fabricated Statically & Dynamically Balanced. WEIGHT 2 Ton – 17 Ton RPM 300 – 750 MOUNTING It should be Mounted on EN-8 forged steel shaft fitted withDouble Row Spherical Roller Bearing & Brackets & Pedestals.

...more

Billet Ejector

The heavy duty pushers are rolling mill duty, used for pushing the raw ingot into furnace. It will be installed in backside of furnace in rolling mill. The double stands ejectors will be installed in front side of furnace, eject hot ingot ready for rolling from the furnace

...moreBe first to Rate

Rate ThisOpening Hours