Oil Filter Press

280,000 Per Piece

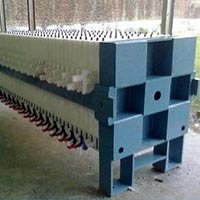

Manual Filter Press

Get Price Quote

1 Piece (MOQ)

We own a well-structured warehouse with the help of which we are capable of delivering a flawless range of products. So, you can stay rest assured with us for damage-free products. We are one of the leading names engaged in supplying an extensive array of Manual Filter Press. Advantages of Manual Filter Press : Maintenance Free Cost saving Easy to Operate.

Best Deals from Cast Iron Filter Press

Zero Holp Up Filter Press

Get Price Quote

The Cartridge assembly consists of plates, perforated screens, spacers and fitter media. Interlocking spacers internally form single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquids spreads out equally on each plate fitted with filter media. Solids remain on filter media and clear. filtrate flows through precisely made holes on sides of plates and collects in the shell, which then comes out through the outlet. In this process, solids are evenly distributed on each plate. The cake is then cleaned from the filter material and used again for filtration process. -> Single pass filtration with no solid bypass ' -> Full batch recovery, no separate scavenging system needed. -> Proper sealing which allows the filtration of volatile, toxic and inflammable products. Plate pack arrangement ensures : Any type of filtering media singularly or in combination, can be used to achieve required micron efficiency. Easy removal and cleaning of the Cartridge Assembly. Closed System ensures : Filtration of toxic, hazardous, explosive materials. Efficiently cleaned and sterilized. Central feeding ensures : No solid inside the vessel, complete recovery of liquids. Cake solids can be maximum dried with N2 Complete cake retains over the plate. Uniform filter-aid bed can be formed. Reduces the cost of expensive solvents.

Waste Water Filter Press

Get Price Quote

We are one of the leading organization engaged in providing excellent quality Waste Water Filter Press, which are manufactured by using high grade material. These Waste Water Filter Press are widely appreciated by our clients which are situated all round the nation. We are also offering Ceramic Filter Press.

Zero Hold Up Filter Press

Get Price Quote

The Cartridge assembly consists of plates, perforated screens, spacers and fitter media. Interlocking spacers internally form single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquids spreads out equally on each plate fitted with filter media. Solids remain on filter media and clear. filtrate flows through precisely made holes on sides of plates and collects in the shell, which then comes out through the outlet. In this process, solids are evenly distributed on each plate. The cake is then cleaned from the filter material and used again for filtration process. Single pass filtration with no solid bypass Full batch recovery, no separate scavenging system needed. Proper sealing which allows the filtration of volatile, toxic and inflammable products. Plate pack arrangement ensures :Any type of filtering media singularly or in combination, can be used to achieve required micron efficiency. Easy removal and cleaning of the Cartridge Assembly. Closed System ensures :Filtration of toxic, hazardous, explosive materials. Efficiently cleaned and sterilized. Central feeding ensures :No solid inside the vessel, complete recovery of liquids. Cake solids can be maximum dried with N2 Complete cake retains over the plate. Uniform filter-aid bed can be formed. Reduces the cost of expensive solvents.

Membrane Filter Holder

Get Price Quote

We are offering a complete range of equipment for Membrane filtration, both for laboratory & production scale operations. Stainless Filter Holder for 90 mm & 293 mm membranes. Stainless Steel Pressure Vessels. 5 lts, 20 lts., & 100 lts. Sterility Testing Units. Single- 3 place- 6 place. Pressure Regular with Air Filters.

Fully Automatic Filter Press

Get Price Quote

An automatic filter press has the same concept as the manual filter and frame filter, except that the whole process is fully automated. It consists of larger plates with mechanical “plate shifters”.The function of the plate shifter is to move the plates and allow rapid discharge of the filter cakes accumulated in between the plates. It also contains a diaphragm compressor in the filter plates which aids in optimizing the operating condition by further drying the filter cakes.

Zero Hold Up Filter Press

Get Price Quote

The J K Industries is a one of the well known manufacturer and supplier of filter presses. The zero hold up filter press machine is made using high quality stainless steel and has a well structure design. Some of the main parts of this machine are filter plates, perforated screens and spacers and filter media. The working process of zero hold up filter press machine is same as sparkler filter press. The main difference is it works exactly the opposite direction of flow of liquids to the flow in standard filter. Therefore, it is also called reverse flow zero hold up filter press. One can use N number of plates as per their diameter. This filter press machine is mainly used for thin liquids.

Semi Automatic Filter Press

Get Price Quote

Semi Automatic Filter Press, hydraulic closing filter press

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press, Sparkler Filter, Chemical Machinery

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press, Liquid Manufacturing Plant