Woven Fabric / Label / Laces

Woven Fabric / Label / Laces has traditionally been an accessory for the main garment and are the creators of brand value of the garment. Thus it constitutes an important role in Garment manufacturing and is used by both the Garment Exporters as well Domestic Garment manufacturers. GOPALA, has a state of art imported Plant for manufacturing Labels. The Jacquard Looms are imported from Switzerland with supporting CAD studio and pattern creating & weave software supplied by the Plant Manufacturer itself. The Company has further machines for value added functions like Cut & Fold, Filled Label machine, Ultrasonic Laser cutting machine which help the Company to cater to the add on requirement of Garment manufacturers. We can match 1800 different shades of yarn. LABEL SPECIFICATIONS woven from 100% polyester filaments Slitted edges on looms Ultrasonic edges – off loom cutting Taffeta and Satin labels Width ranging from 10 mm to 200 mm Upto 12 different weft colours incl. ground colour. Stiff /soft finished labels PRODUCT FORMATS Continuous tape in Roll Form. Cut Seal. Cut Fold in End fold, Centerfold and Mitre fold. Filled / Stuffed labels Die-cut / Laser cut labels Ready-to –stick labels (backside double adhesive tape)

...more

wall putty bags

These bags are durable, presentable and easy to handle. We manufacture BOPP laminated bags for packing of minimum 5 kg to maximum 50 kg units. India’s leading brands preferred and have changed to this kind of bags. Excellent Clarity Low Electrostatic Charge Waterproof Reverse Printing

...more

PP Woven Sacks

Woven Sacks are the best and the most cost effective packaging solution for Industries like Cement, fertilizer, sugar, Chemicals, foodgrains etc. There are various types of bags made out of PP/ HDPE and with or without lamination. Apart from it there are Jumbo bags which are used to pack bulk quanitities. Off late Woven fabric which is the first stage of Woven sacks, is a preferred medium for bale wrapping and rain protection in the form of Tarpaulin.Today majority of woven sacks manufacturers are into different products from the above and GOPALA manufactures bags for cement, sugar, food grain and rice packaging. Originally the company specialized in Cement packaging and this has helped the Company get associated with the best of the Cement manufacturers in the Country with some of the Companies sourcing their packaging requirement from the Company for the last 15 years and more. The Company is presently manufacturing woven sacks for : CHARACTERISTICS OF BOPP (BIAXIALLY ORIENTED POLYPROPYLENE) High Tensile Strength Excellent Clarity Low Electrostatic Charge Waterproof Gujarat Ambuja Cements Limited Ultratech Cements Ltd. – (erstwhile Cement Division of L & T) JK Lakshmi Cement Ltd. ACC Limited Sanghi Industries Ltd. – Cement Divison Shree Cement Limited Birla Corp Limited Other than Cement, the company supplies to the following sugar companies and state governments for food grain Triveni Engineering and Industries Limited Balrampur Chini Mills Bajaj Hindustan Adani Wilmar State Government of Punjab State Government of Madhya Pradesh The Company has recently entered the export market and already has two major buyers in the middle east and USA Kanak Exports, USA Sun Packaging, Oman The Company has the best insfrastructure in terms of Factory Building and Plant & Machinery. At its Santej works the Company has four Tape extrusion plants which are supplemented with 170 Circular Weaving Looms and other Quality Control Equipments. The Abu Road and Santej works houses the Finishing division with Automatic Cutting & Printing Machines and Stitching Machines.

...more

pp valve bag

The brick-shaped PP woven sack, produced without adhesives by heat welding of the coating on the fabric, was developed with automated filling and handling processes in mind. The sack can be produced either as a one-layer block bottom valve bag or as an open mouth bag with a block bottom. It surpasses all comparable products as far as resistance to breakage is concerned, is versatile and also eco-friendly and economical.

...more

pp cement bag

Woven Sacks are the best and the most cost effective packaging solution for Industries like Cement, fertilizer, sugar, Chemicals, foodgrains etc. There are various types of bags made out of PP HDPE and with or without lamination. Apart from it there are Jumbo bags which are used to pack bulk quanitities. Off late Woven fabric which is the first stage of Woven sacks, is a preferred medium for bale wrapping and rain protection in the form of Tarpaulin.

...more

Polypropylene Woven Sack

Woven Sacks are the best and the most cost effective packaging solution for Industries like Cement, fertilizer, sugar, Chemicals, foodgrains etc. There are various types of bags made out of PP HDPE and with or without lamination. Apart from it there are Jumbo bags which are used to pack bulk quanitities. Off late Woven fabric which is the first stage of Woven sacks, is a preferred medium for bale wrapping and rain protection in the form of Tarpaulin.

...more

Laminated Pp Bag

These bags are durable, presentable and easy to handle. We manufacture BOPP laminated bags for packing of minimum 5 kg to maximum 50 kg units. India’s leading brands preferred and have changed to this kind of bags.

...more

BOPP Packaging Bags

These bags are durable, presentable and easy to handle. We manufacture BOPP laminated bags for packing of minimum 5 kg to maximum 50 kg units. India’s leading brands preferred and have changed to this kind of bags.BOPP Laminated PP Woven Bags with Gussets, (Centre Gusset or Off Centre Gusset) BOPP Laminated PP Woven Bags with Liner, (Inside liner – loose or bottom stitched)

...more

bopp laminated woven bags

Multi Color Printed Bopp Laminated PP Woven Bags increase Brand Value with its excellent printing, beautiful designs, attractive display and aesthetic appearance. These bags are durable, presentable and easy to handle. We manufacture BOPP laminated bags for packing of minimum 5 kg to maximum 50 kg units. India’s leading brands preferred and have changed to this kind of bags.

...more

BOPP Laminated PP Woven Sacks

Multi Color Printed Bopp Laminated PP Woven Bags increase Brand Value with its excellent printing, beautiful designs, attractive display and aesthetic appearance. These bags are durable, presentable and easy to handle. We manufacture BOPP laminated bags for packing of minimum 5 kg to maximum 50 kg units. India’s leading brands preferred and have changed to this kind of bags. CHARACTERISTICS OF BOPP (BIAXIALLY ORIENTED POLYPROPYLENE) High Tensile Strength Excellent Clarity Low Electrostatic Charge Waterproof Reverse Printing Good Performance for High Speed Printing Corona Treatment on both the sides TYPES BOPP Laminated PP Woven Bags – Single Side,(only one side Printed Bopp and / or other side Flexographic Printing) BOPP Laminated PP Woven Bags – Both Sides,(Both Side Printed Bopp) BOPP Laminated PP Woven Bags with Gussets,(Centre Gusset or Off Centre Gusset) BOPP Laminated PP Woven Bags with Liner,(Inside liner – loose or bottom stitched) BOPP Laminated PP Woven Bags with Perforations,(Perforation on the Sides for aeration) BOPP Laminated PP Woven Bags with Handles and D-cuts,(For easy lifting and mobility) BOPP Laminated PP Woven Bags with Window,(Transparent window either on the sides or front / back for visibility of inside packed product) BOPP Laminated PP Woven Bags with Top Hemming,(Allows opening easily) BOPP Laminated PP Woven Valve Bags.(Facility for on line Packing) APPLICATIONS (FOR PACKING OF) Chakki Atta Rice Fertilizers & Chemicals Seeds Grains & Pulses Tea & Coffee Foods & Spices Animal Feed White Cement & Wall Putty Outer Packing Product Promotions.

...more

Block Bottom Valve Bag

sack concept for cement – in use worldwide, patented internationally, and produced exclusively on Starlinger or Windmoller & Holscher machines. The brick-shaped PP woven sack, produced without adhesives by heat welding of the coating on the fabric, was developed with automated filling and handling processes in mind. The sack can be produced either as a one-layer block bottom valve bag or as an open mouth bag with a block bottom. It surpasses all comparable products as far as resistance to breakage is concerned, is versatile and also eco-friendly and economical.

...more

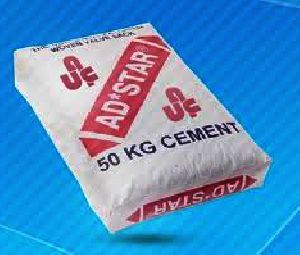

AD*Star Bags

AD*STAR® is a well-known sack concept for cement – in use worldwide, patented internationally, and produced exclusively on Starlinger or Windmoller & Holscher machines. The brick-shaped PP woven sack, produced without adhesives by heat welding of the coating on the fabric, was developed with automated filling and handling processes in mind. The sack can be produced either as a one-layer block bottom valve bag or as an open mouth bag with a block bottom. It surpasses all comparable products as far as resistance to breakage is concerned, is versatile and also eco-friendly and economical. PP fabric is laminated on a PP extruder and printed. This is then loaded onto the AD*Star conversion line. At the end of the production process, the tubular fabric becomes a sack. And it is the conversion line that gives the sack its final, individual form, cutting it to length, sewing it, and adding the desired closure type – or forming a brick-shaped AD*STAR® sack in a special adhesive-free heat welding process. Today, the Indian market has a lack of suppliers for this bag and an increasing demand for superior packaging across all sectors

...moreBe first to Rate

Rate ThisOpening Hours