Vibro Feeder

FEATURES OF MAXWELL VIBRO FEEDER Compact, roughed and stress relieved frame. Trouble free operations due to reliable vibro motors equipped with it. Wear Protection due to liner system. High Adaptability due to customized solutions. Easy adjustment of vibrating to provide regulated feed for medium to small lump sizes.

...more

Vibrating Grizzly Feeder

MGF stands for Mechanical Grizzly Feeder, where as VGF stands for Vibro Grizzly Feeder. Mechanical Grizzly Feeder uses eccentric shaft mechanism for vibration, hence conventional system which is highly acknowledge by customers. VGF stands for Vibratory Grizzly Feeder which are equipped with twin self vibratory motor that generates Vibration. VGF type feeders are equipped with vibratory motors. VGF is robust to use. Both type of feeder provides best feeding option for high intake primary and Super primary Jaw Crusher.

...more

Vertical Shaft Impactor

APPLICATION VERSATILITY Jaw Crushers applies compressive force onto material to be crush that may produces flakiness to the material. Flakiness is not permissible after certain extent because it reduces the strength of the material. Maxwell VSI intakes the screen aterial of specified size into the rotor where it is accelerated to high speed. The Material gets high velocity into the rotor and then it discharge from fixed rotor openings and collide with the rocked outer periphery resulting into crushing. Maxwell VSI crushers offers multi-port rotor designs that provide large application range and crushing technology for rock-on-rock reduction. Maxwell VSI can operate on high rotor speed which provides high crushing ratio. Such high crushing ratio enable Maxwell VSI to produce crush send as well. HIGH ADAPTABILITY The design of this machine is ye, users friendly. The maintenance of this machine is very easy. Any unskilled person with average brilliancy can maintain this machine. All parts are very ergonomically designed which avoids any miss fitment. TROUBLE FREE WORKING Single Point, Centralized greasing system ensures trouble free working. Easy to inspect rotor parts enables operator to ensure the maintenance schedule. HIGH PERFORMANCE, LOW COST Maxwell VSI offers efficient rock on rock reduction that is cost effective due to low wear. All wear parts are made of higher wear resistible steel and easily replaceable that reduces downtime and ultimately reduces operating cost. The optimized design results in low cost spares as compare to other manufacturers.

...more

Vertical Shaft Impact Crusher

Jaw Crushers applies compressive force onto material to be crush that may produces flakiness to the material. Flakiness is not permissible after certain extent because it reduces the strength of the material. Maxwell VSI intakes the screen aterial of specified size into the rotor where it is accelerated to high speed. The Material gets high velocity into the rotor and then it discharge from fixed rotor openings and collide with the rocked outer periphery resulting into crushing. Maxwell VSI crushers offers multi-port rotor designs that provide large application range and crushing technology for rock-on-rock reduction. Maxwell VSI can operate on high rotor speed which provides high crushing ratio. Such high crushing ratio enable Maxwell VSI to produce crush send as well.

...more

Single Toggle Jaw Crusher

DYNAMIC DESIGN The Dynamic design of New single toggle jaw crusher promises efficient engineered product with massive crushing energy. The Design ensured the adaptability of Maxwell Single Toggle Jaw Crusher with stationary, Portable and Mobile Quarring and Mining applications, well suited for contractors due to high portability. MINIMUM DOWNTIME The technological advancement and incorporation of latest trends provides ease of use that reduces downtime. Maxwell Single Toggle Jaw Crusher comes with hydraulic CSS (Closed Size Setting) adjustment for secondary Jaw Crushers and Tapered Wedge adjustment for primary jaw crushers. Lubrication circuit ensures easy and reliable lubrication through centralized greasing. RELIABLE PERFORMANCE The continuous development of Maxwell Jaw Crushers offers highest possible fatigue strength and excellent reliability due to rigid body frame, high-quality cast steel components and premium spherical roller bearings. No matter What you crush — from hard and abrasive rock to various recycling materials — you'll get the prime solution with the Maxwell jaw crushers. HIGH ADAPTABILITY With wide range of sizes and models available, Customers are having ample alternatives to choose from which gives best returns to their investment.

...more

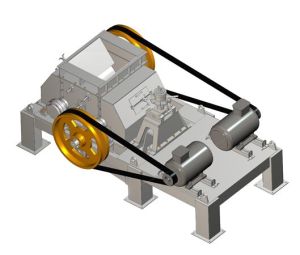

Roll Crusher

ROBUST DESIGN The design of Smooth Double Roller Crusher is robust to cater the customer need. It has the reliable and easy CSS Setting through square threaded Jack System. Roll fitting is through tapered casted hub ring. Heavy-duty bearing pedestal with ease of operation. MINIMUM DOWNTIME The Maxwell Smooth Double Roller Crusher has very easy and accurate CSS setting through Square threaded Jack without insertion of Sims or any additional part usage. The Roll change is easy as it is locked with tapered locking hub ring. RELIABLE PERFORMANCE The fully machined roll and tapered licking system delivers troubled free performance. Reliable material usage of shaft and proven performance of bearing gives consistent performance. The specially designed volute spring eliminated any crushing shocks with unified crushing size.

...more

Horizontal Shaft Impactor

FEATURES OF MAXWELL HORIZONTAL SHAFT IMPACTOR Higher Capacity with simple structure. Easy handling of rotar blade replacement High Effciency and energy conservation. Easy adjustment of breakers blades. Full body protection through efficient and cost effective liners.

...more

Grizzly Feeder

APPLICATION AND USER PREFERRED OPTION TO CHOOSE BETWEEN MECHANICAL OR ELECTRICAL VIBRATOR MGF stands for Mechanical Grizzly Feeder, where as VGF stands for Vibro Grizzly Feeder. Mechanical Grizzly Feeder uses eccentric shaft mechanism for vibration, hence conventional system which is highly acknowledge by customers. VGF stands for Vibratory Grizzly Feeder which are equipped with twin self vibratory motor that generates Vibration. VGF type feeders are equipped with vibratory motors. VGF is robust to use. Both type of feeder provides best feeding option for high intake primary and Super primary Jaw Crusher. DOUBLE DECK CONSTRUCTION TO CATER EXCELLENT FEEDING AND SCALPING AT 2 DECKS Grizzly Bar separates unwanted fines and material smaller than the output size of primary crushers. Unwanted fines are further separated by second deck that improves overall productivity and finished material quality. Material Smaller than the out size of the Primary Crusher is by pass to the discharge conveyor and mixed with the out put from primary crushers. RIGID CONSTRUCTION TO CATER HEAVY DUTY APPLICATION Our Grizzly feeders have rigid structure to withstand all impact stress and accommodate large sized lumps that are fed into the primary crushers. We provide high abrasion liners to protect the body of the feeder. COMPACT AND MODULAR DESIGN FOR HIGH ADAPTABILITY Both type of feeder have the same outer specifications with optimum design to easily fit into the skid or track mounted stations. MASSIVE VIBRATING FORCE WITH ADJUSTABILITY MGF and VGF type of feeder are both having massive vibrating amplitude. Both type of feeder have adjustment to achieve desired vibration amplitude. Massive Vibration force also helps resolve the interlocking of large lumps in hopper.

...more

Double Toggle Jaw Crusher

EFFICIENT DESIGN Highly efficient design delivers maximum performance as compared to other competitive manufacturers. We have proven our self in the hardest stone which earned customer satisfaction. Optimized design offers low cost spares. BEST KINEMATICS Optimized Crusher cavity, effective nip angle, kinematics and operating parameters fully guarantee the excellent productivity for which MAXWELL double toggle jaws are known and valued. Cavity area is in accordance with the intake material s.e. Nip angle, which is critical for productivity and trouble free operation is maintained M each of the model. PROVEN MATERIAL TECHNOLOGY Proven material technology and finest quality component shield excellent design and provide durability. Body frame comprises of high quality steel plates and casted blocks creating a frame structure full of strength. Specialized manganese steel provides protection to all other mother parts in cavity area. Shaft, Toggle, pitman, toggle pin and other parts is made of high quality steel alloys providing seamless functionality without the fear of fault or breakage. Massive rigid eccentric shaft of special steel is carried in self-aligned spherical roller bearing of ample capacity which ensure smooth running. EASY OF USE Easy mechanism to adjust css setting using setting flats. Exclusive functionality of reducing the intake size M larger size jaw crushers to further decrease css setting to maintain adequate nip angle. Swing Jaw assembly is totally bolted with the body frame for easy maintenance HIGH ADAPTABILITY Wide range of sizes and models available to choose from for Primary and Secondary crushing need.

Max. Feed Size : 300 mm

...more

Cone Crusher

PROVEN DESIGN Maxwell S type Cone Crusher is world renowned and Pioneer technology in the world. Due to proven and optimized design , it provides high efficiency, strong crushing force, high yield and low operation cost. HIGH EFFICIENCY Effective Cavity design according to the crushing principles and the fast spinning crushing head delivers high efficiency at low power consumption. ROBUST CONSTRUCTION Rugged body frame made of special cast and heat-treated steel capable of withstanding strong impact during the operations. TROUBLE FREE OPERATIONS Maxwell S type Cone crusher are equipped with Hydraulic System for CSS Adjustment. Easy removal of clogged material inside the crushing chamber by hydraulic lifting system. Fan Cooled External oil circulation system provides stable oil supply to the machine. Oil Circulation system can be interlocked with main motor for additional safety. The spring loaded release system protects the machine against the uncrushable material. OPTION OF CRUSHING CAVITY FOR DIFFERENT USER REQUIRED Maxwell SF type cone is equipped with short head cone for fine crushing. Maxwell SF type cone is equipped with standard head cone for coarse crushing.

...more

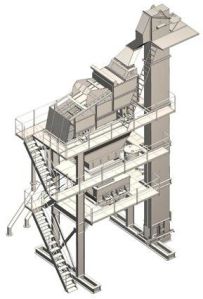

batch mix plant

Be first to Rate

Rate ThisOpening Hours