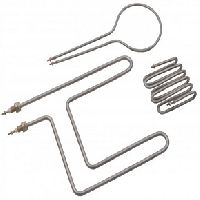

Tubular Heating Elements

We are one of the front line suppliers of a huge range of tubular heating elements. Ceramic Heater and Heat Proof mica Band Heaters. Especially designed and automotive models to meet the ever increasing demand for energy conservation and to improve operations efficiency of production unit and also capable of generating higher temperature for plant whatever the machinery required, available in different watts, volts, lengths, width, customized according to processing of heat for machinery in Industries. our range is also designed in perforated sheathing for the purpose of air-cooled application. Adding on, our gamut of mica, ceramic band heaters and nozzle heaters is covered with heating proofing pads to save energy and Heat loss.

...more

Tubular Heaters

Material: Stainless steel, Encloy, copper, Mild Steel, Wattage/Power: 100 – 6000 Watt. Operation Running Voltage: 24 volt, 220 volt, 230 volt, 240 volt, 415 volt Available: In .312″, 375″, 430″, 475″and.625″ element diameter. Temperature Up to 850° F /550° C. Tubular / manifold Heaters A designed helical coil of Nickel-Chromium alloy resistance wire with the ration of 80%-20% is welded to nickel-coated steel terminated cold pin. Once this coil assembly is stretched and centered in the element sheath, then the coil is filled with MgO (Magnesium Oxide) powder. Tubular heaters are the widely used heaters in many commercial, industrial and scientific applications. The Tubular heater can be formed in any shape and cast into elements. Once the coil is filled with MgO powder, it is then compacted to permanently stabilize the coil in the center of the tube. Tubular heaters are also called electric tubular heaters. Ultimately, a good quality of tubular heater provides excellent rapid heat transfer, dielectric strength between coil and sheath, durability with an industry resistance tolerance of -5%,+10% which reciprocate and translate to wattage resistance tolerance of -10%,+5%. Length tolerance of tubular heater is +/- 1% with available customized diameter of tolerance +/- 1%. Watt density of tubular heaters will govern internal resistance wire temperature and sheath and is calculated with the following formula: Watt Density (w/in2) = Element Wattage / (π × Element Dia. × Element Heated Length) Water heating coil or the electric heating coil is used in winters everywhere to heat the water for bathing and drinking. Following are the elements to construct tubular Heaters: Tubular sheath material selection: It is based on chemical composition of the gas or liquid being heated, process control and the characteristics of elements entering into solution. Incoloy® 840 for maximum sheath temperature: 1600°F / 871°C (Air Heating Application) Incoloy® 800 for maximum sheath temperature: 1600°F / 871°C (Air heating, immersion heating of portable water and liquid applications) 316 Stainless Steel for maximum sheath temperature: 1200°F / 649°C (improve corrosion resistance used in deionized water) 304 Stainless Steel for maximum sheath temperature: 1200°F / 649°C (Industrial, Medical, and Chemical Application) 321 Stainless Steel for maximum sheath temperature: 1200°F / 649°C (To prevent carbide precipitation in certain medium) Copper for maximum sheath temperature: 350°F / 177°C (used for clean heating water) Steel for maximum sheath temperature: 750°F / 399°C (used for high to low viscosity oils, asphalt, tar, wax, molten salt, heat transfer liquid media) Inconel ® 600 for maximum sheath temperature: 1800°F / 982°C Incoloy® 825 for maximum sheath temperature: 1100°F / 593°C Same like this, you need to define your sheath surface treatment material, termination style and option with mounting methods, bending formation and moisture seals in standard sizes and ratings. For orders and inquiries of the Tubular heater, one needs to specify the following requirement to manufacture company. As well as you should know about tubular heater manufacturers and heating coil manufacturers. Some of the eaters are called ring heaters, as they have round shape. Shape, dimensions Application purpose, medium Tube diameter, material, unheated tube length Installation and fastening elements Electrical connection Voltage, power rating Desired quantity Once you provide these requirements, ask for quote and order! If you have any question or any query. Please contact us if want to know about some more about our product. Product Details: Minimum Order Quantity: 6 PiecePower(Watts): As per requirement of applicationVoltage: As per requirement of applicationSize: As per requirement of application

...more

Tubular Band Heaters

220 Per Piece

Porcelain Heater

Porcelain Heaters are produced from best quality of raw material and extraordinary temperatures bearing insulators, the Porcelain Heaters provide is used in various industries. The Porcelain Heater is the combinations of the elements that are bare partly in air for better heating Transfer Process for the application, plant and machinery. Porcelain Heater is widely used in ovens, tanks wherever there draining cannot be possible to change the Electric heaters. The Porcelain Heaters offered by Antique Heating Elements are known for their extraordinary accuracy, performance and durability.

...more

Pencil Heater

A leading pencil heaters manufacturer in Ghaziabad. Pencil heaters can be deliberated “Small heaters” that are meant to produce heat in various applications by their low density and high density. Cartridge heaters are principally used in molds and fit inside a cavity and helps heat solids by attainment of high temperature (by High Density Cartridge Heater or High Density Pencil Heater). Pencil heaters have the flexibility of being capable to fit thermocouple inside to help control temperature ofindustrial heaters more precisely. Various dimensions allow for it to be used in any opening and can be customized with any cold section. Lead wires range from the end to your control panels. Pencil heaterscartridge heaters are also used as a water heater element and in an extensive diversity of applications. Specific of these procedures include bag sealing application, hydraulic oil application, motor oil application, gearboxes, water heating application along with laboratory and food equipment. Sheaths can grasp extreme temperature as Pencil heaterscartridge heaters can be aimed with greater watt densities.

...more

Oven heating element

Finned heaters or Antique finned tubular heaters are type of electrical finned tubular heaters. which are used in diversity of heating applications. Whereas making and scheming of theheating element for oven, one desires to use the optimum material such as stainless steel, Incloy, mild steel, Inconel, titanium alloys or steel.

...more

Mica Heaters

Mica Heaters Mica heaters are the terrific choice when cost and performance succeed substrate flexibility. Mica is a firm substrate able to resist very high temperatures and is used for applications where heat is up to 500°F (260°C). These heaters can be designed in an extensive range of different sizes and watt densities and their high Watt densities are up to >100/in² (15.5W/cm²). Mica heaters are manufactured for operations where effective temperature is much higher, leakage is lower and material cost is also low in comparison to other flexible heater technology.Such as packaging equipment, food service equipment, air heaters etc. Mica Heaters can simply be designed to accommodate a multiple of components such as thermocouples, thermistors, thermostats, thermal fuses, RTDs, or specialty wiring joints. Mica heaters are also referred as Micathermic heaters, which is a type of space heater wherein heating element is covered with a thin sheet of mica. These heaters generate both radiant and convection heat, these are generally thinner in comparison to other types of heaters.Applications of Mica Heaters Rubber vulcanizing machine Tank heating Extrusion machine Semiconductor processing Plastic Processing Blown film dies Heating of nozzles of injection molding machine Air heaters Enclosure systems Mica Heaters offers comprise class mica heating element that delivers superior heating efficiency with adjustable thermostat backing so as to provide optimum functional support. Further, Mica heaters are manufactured with IP23 power switches and inbuilt thermal cut-off preference for safe and secure jobs. Flexibility is its most important feature and they can be mounted on a wall or could be used in standing option which increases efficiency and economical working solutions that meet specific heating requirements. Moreover, these heaters can manage maximum covered temperature of 900°F with customized power, voltage and size options, which is most convenient and suitable for plastic industry. Plate Heater are used nowadays for several applications like as extruder barrels, hot plates. All these heaters like electric space heaters, band heater or electric heater have their own importance for the various products but some time they act as same in some fields. Some of them are heating elements as well. Terminations of Mica Heaters Mica heaters are available with many types of electrical terminations. The termination styles are selected according to amperage, diameter, electrical safety, voltage and cost. Three main termination styles are: Lead Wire Terminals- In lead wire terminals High-temperature wire is internally connected to the band heater. These terminals has maximum amperage up to 20 Amps European Plugs – European plugs are safe and simple to use and are generally used where the electrical termination has to be detached regularly. Screw Terminal- Stainless steel screw terminals are generally suggested when high amperages (up to 30 amps) are implicated and the temperature restriction is 840°F. Feel free to ask your query whatever it is about the product. You can contact us also if want to know more about the product. Product Details: Minimum Order Quantity: 6 PiecePower(Watts): As per requirement of applicationVoltage: As per requirement of applicationSize: As per requirement of application Specification:- Brass tubular sheath (available in stainless steel for corrosive materials such as PVC). Power standard density: max brass 5 W/cm² or 25 watt/sq. inch. Tear-resistant connection of power cable of Teflon wire or glass wire according to wattage required for application Diameter is available from 25 mm up to 1500 mm. Height is available from 25 mm up to 800mm. With mounted Thermocouple “K type” or “J type” is available. Inner sleeve is made of Steeliness steel, mild steel, Copper, brass. Features:- Versatile. Compact structure. Efficient and Reliable.

...more

K Type Thermocouple

Temperature measuring point : Pick shell / insulation / dew point. Thread : 4/1, 5/16, M8, M6, M12. Temperature range : -50°C~950°C. K Type Thermocouple is the most common type of thermocouple. It is reliable, inexpensive, and accurate and its temperature range is wide. It is mostly used in nuclear applications due to the relative radiation hardness. The maximum temperature (continuous) is nearly 1,100°C. These types of thermocouples are used widely in the industry. They have very good resistance to oxidation and high thermopower. They provide us with correct temperature monitoring in the range between -200°C and 1370°C (-328°F to 2498°F). They consist of nickel-5% aluminum and silicon (-) wire vs. nickel-10% chromium (+) wire. One should use this kind of thermocouple in oxidizing or inert atmospheres. The heating element like electric heaters is the best source to heat it up. They are mostly used at temperatures over 540°C (1004°F) because of the higher oxidation resistance as compared to J, T or E types of thermocouples. The range of K Type Thermocouple : Extension wire – Between 32° F and 392° F (0°C to 200°C) Thermocouple grade wire – Between 454° F and 2,300° F (–270°C to 1260°C) Accuracy (which will be greater) :Special Limits of Error – +/- 1.1C or 0.4% Standard – +/- 2.2C or +/- .75% Names of Elements : For describing the positive element of this type of thermocouple (KP), following names can be used: ThermoKanthal-KPs, HAI-KP1, Tophel+, Nickel-chrome, Chromel2, and T-13. The negative element of this type of thermocouple (KN), is described by these names: ThermoKanthal-KNs, HAI-KN1, T-2s, Nial+, Nickel-silicon, and Alumel2. Cautions to Take: Some conditions should be avoided while using this type of K thermocouple. It should not be used in vacuum applications because of the vaporization of chromium in the positive element. Also, it is not supposed to be used in the sulphurous environment as both of the elements will corrode rapidly and eventually the negative element will fail mechanically because of being brittle. One should also avoid reducing atmospheres. The green-rot phenomenon can be caused due to low oxygen levels. In this phenomenon, chromium in elements will start oxidizing which cause very large negative drifts in calibration. Take a look here as well, actually, If you are a wholesaler then you can have direct contact to thermocouple manufacturers near your area for bulk order. Type K Thermocouples are specified at the time when metallurgy was not as advanced as it is nowadays. As a result, the characteristics can vary extensively between samples. Nickel which is the constituent metal of K type thermocouple is magnetic. Thermocouples made with magnetic material have a characteristic that they are subjected to a deviation in output whenever the Curie point is reached by the material. This happens with thermocouple type k at nearly 185 °C. Hope you like the content and him information given by us. If still have any query about the product or anything then don’t forget to contact us. FEATURE:- Premium Quality. Affordable Reliable Product Details: Minimum Order Quantity: 6 PiecePower(Watts): As per requirement of applicationVoltage: As per requirement of applicationSize: As per requirement of application

...more

HIGH DENSITY PENCIL HEATERS

High Density Pencil Heaters High Density Pencil Heaters are proven to be the low cost solution for most of heating applications. They are suitable for many assorted applications. They are produced in a manner so that its future applications and execution encroach other cartridge radiators. High Density Heaters are manufactured with high quality materials so that they can operate in any extreme condition also. Main areas of use of these heaters are tools heating in foundry technology, packaging-machines, medical devices, plastics-plants, Automobile industry, paper Industries Machinery, Plastics processing Machinery etc. If talk some more about it then Cartridge heaters manufacturers mainly show the grade of heater available in the market nowadays. Bolt heaters are also used for preheat process and holding heated bolts. Key Features: High radiance magnesium oxide fill choose for the biggest kick to the bucket electrical quality. Very compacted, warm conductivity for the most extreme hotness exchange. Safety wire of chromium-nickel for the extreme warmer life, equitably wound for hotness conveyance. Stainless Steel 304 sheath for safe oxidation in many situations. Nicolay and Stainless Steel 316 are accessible likewise. Lead wires of these heaters are of high temperatures Like Teflon Wire and Glass Wire. Can be accessed with inbuilt thermocouple of J Type Thermocouple and K Type Thermocouple. In our Company, We Are Manufacturer the High Density Cartridge Heater With power/Wattage is between 100 and 4000 watts. So, they are appropriate for most of the industry applications for fast delivery of Electric Heaters Heating Process. Benefits of High Density Pencil Heaters Smaller Bolt heaters can be used without sacrificing of life anticipation because of high density Wattage. In this way, we can save cost and Energy (long-term and up-front). Maximum support is provided through swaged construction for the resistance wire to eliminate the effects of shock, vibration and Electric Heaters Heating loss. High density transfer characteristics that allow improved life anticipation as compared to other style, size and type of Electric heaters. Special features and termination styles permit customization to any application. The extensive line of controlling devices and accessories provide us with complete solution for industrial heating problems by Industrial Electric Heaters. Applications up to 8200C (15000F). Typical Application of these Heaters Plastic Molding Heating Gases and Liquids Plastic Extruders Dies and Molds Food Processing Packaging Equipment Shoe Machinery Medical Equipment Hot Stamping Glue Guns Hot Runner Molds Custom or Standard DesignsHigh Density Pencil Heaters are designed and manufactured in such a way to meet our requirements by industrial Heaters Manufacturers. They are designed in a complete range of physical dimensions, lead terminations and standard electric Heaters ratings. Cartridge heater which is a tube shaped like structure and used for heating element in the heating process. Electric Heaters are also a best choice for heating process. You can find a variety of High Density Pencil Heaters in our company. These industrial Electric heaters can be customized for special applications to suit any individual needs for Electric Heating process, for example, individual connections and special power/Wattage, Voltage distribution for easy installation. Hope you will like the technical Information of high Density cartridge Heaters, so please post and share your query by contacting us. Features: Available within Built in ‘J’ Type Thermocouple or ‘K’ type Thermocouple. Rugged & Durable Construction of Electric Heaters. Available as per process required For Customized Heating. Product Details: Minimum Order Quantity: 6 PiecePower(Watts): As per requirement of applicationVoltage: As per requirement of applicationSize: As per requirement of application Temperature: Maximum sheath temperature 800oC. Material: Nickel Chrome Resistance Wire, Stainless Steel Tube Temperature: Temperatures to 1400oF (760°C) on Incloy sheath, >temperatures to 1000oF (540oC) on optional stainless steel sheath.

...more

High Density Cartridge Heaters

High Density Pencil Heaters are confirmed to be the small cost solution for most of the warming applications. High density cartridge heater appropriate for many multifarious applications. Cartridge heater shaped in a way so that its upcoming applications and effecting encroach other cartridge radiators.High Density Heaters are manufactured with high class materials so that they can function in any extreme condition also. Main areas of use of high density cartridge heater are tools heating in foundry technology, packaging-machines, medical devices, plastics-plants, Automobile industry; paper Industries Machinery, Plastics processing Machinery etc.If talk some more about it then high density cartridge heater manufacturers mainly show the grade of heater available in the market nowadays.

...more

glass heaters

Glass Heaters: Chrome Nickel Steel With Power Saving Designed for Higher Temperature Available with Heating Proof Pads and Plates Standard Quality Nichrome wire for Uniform Temperature Maximum Amperage Carrying Capacity Easy to Configure and Install

...more

furnace heaters

Furnace heaters Furnace Heater or electric furnace heater are very enclosed device which is used for high-temperature heating, is derived from a Greek word Fornax which ultimately means oven. There is much difference of heater such as electric heater, industrial chemical heater etc. Out of these types of heater, furnace heater is used for power generation, garbage disposal and applicable in oil and gas industry. Quartz heater are also available in the market, which are very useful in the winter season. There are 2 types of furnace heater i.e. Natural gas or Propane gas wall furnace heater which could be used with a cabinet-mounted thermostat. Furnace heater or electric heater can be installed within the wall or surface mounted on the exterior wall which varies horizontally through the wall. There are many models available online based on heat capacity, material and their temperature ranges. A furnace heater works by blowing heated air through the ducts which deliver the warm air to rooms throughout the house via air registers or grills. This heating system is known as forced air distribution system or ducted warm air system which is powered by the electricity, natural gas or fuel. Furnace heaters are the very useful appliance for the peoples who live in cold region. Normally, a home furnace is divided into 3 parts i.e. Burners, heat exchanger, vent and draft inducer. It is a forced air heating system which is used when the indoor air temperature is less than the temperature settled on the thermostat. The required size and heating capacity of furnace heater depends upon the room size. If the size of your room is large, then you need to add the heating capacity of your furnace heater so that you could feel the warmth of the home. While using furnace heater, condensing furnaces are designed to reclaim escaping heat well below than 140F where water vapor in the exhaust gasses into water. If you are looking for the good quality of furnace heaters, then it is the primary source to identify it. What to check before purchasing any furnace heater or a boiler? Efficiency of a Fossil-fuel furnace or Combustion Efficiency Required and Given heating capacity Large grills or an electric fan situated in furnace heater Furnace size: Firstly determine the total area of your home and type of insulation used to determine furnace size. If the size is small, it will take more time and energy consumption to distribute heat in the whole area. free standing or recessed in the wall Finally, if you have any question regarding furnace heater, don’t hesitate and let us know in a comment box. Even, you could add your phone number to get the prompt reply from our support team. Hope that all the information will be liked by you about the product and if still have any query the please contact us. Product Details: Minimum Order Quantity: 6 PiecePower(Watts): As per requirement of applicationVoltage: As per requirement of applicationSize: As per requirement of application

...more

Finned Heaters

Finned heaters or finned tubular heaters are the electrical finned heating elements used in a variety of heat applications. While constructing and designing the tubular heaters, one needs to use the finest material such as stainless steel, Incoloy, Inconel, titanium alloys or steel. This material is decided based on the application of the material such as steel for alkaline cleaning solutions, incoloy for degreasing & cleaning solution, stainless steel for food processing equipment etc. These heaters can be of any size and shape based on your requirement. High-quality MgO (Magnesium Oxide) is also used for efficient heat transfer from resistive coil to your medium either it is air, liquid or solid. Specification of Finned Heaters: Superior internal electrical insulation and heat conductivity Available in a broad variety of sheath materials (corrosive or noncorrosive), heating element watt density, diameters, and ratings whereas standard diameters are 0.260 inches, 0.315 inches, 0.375 inches, 0.430 inches, 0.475 and 0.625 inches. Maximum Sheath Temperature range: 455°C (850°F) Durable Easy to maintain Precise and easy control of heat output Application of Air finned Tubular Heater: Drying Heat Treating Load banks Curing Annealing Features of Tubular heater: Versatile: ideal for comfort and industrial process air application Fins: permit quick heat transfer to the air Easy Installation: Tubular heater can be designed in such a way that it could fit as round or rectangular ducts in the appliance. Tubular air heaters are used for the heating of air (stoves), for ventilation and air conditioning devices, pipelines and annealing. Before purchasing tubular air heater, specify your use with the following details: Now a days many examples can be seen in the market for household works like electric heater which are easy to carry as well as they are small heater, as well as oven heaters or we can say electric oven heating element. All these type of gadgets are used in heating and known as heating element. The requirement of Tubular Heater: Watt density of heating element Sheath material with temperature, the degree of aeration, air velocity, the ambient temperature of the product. Custom bends Once you finalized the following things, you could ask for a quote and if it meets your need – Order It! If you want to ask something, or you have any query then please contact us to know about the product. Product Details: Minimum Order Quantity: 6 PiecePower(Watts): As per requirement of applicationVoltage: As per requirement of applicationSize: As per requirement of application Wattage/power:1500 watt to 30000 KW. Ambient Temperature: up to 400°C. Material: carbon steel with nickel plated. Operation Running Voltage: 220 volt, 240 volt, 480 volt, 600 Volt.

...more

E Type Thermocouple

E Type Thermocouple Thermocouples work as a temperature sensors for control and measurement. They are also used for converting a temperature gradient into electricity. There are two legs made of two different metals wires. These two legs/wires are bonded through welding, and at one end. This joint may be termed as a junction. This junction is the point where temperature finally gets read. Once you have measured something and there is a slight change, you will yourself feel change of voltage. Different characteristics are possessed by different types of Thermocouples. Here we will discuss the features and limitations of E Type Thermocouple. Everyone knows that if you are making any thermocouple product then heating element is very necessary, as I recommend to use electric heatersin such cases if want proper heat on the same time. E Type Thermocouple : E Type Thermocouple has potent to catch the signals with better and higher accuracy. Range of E Type Thermocouple : Extension wire – 32°F to 392°F which is equal to 0°C to 200°C Thermocouple grade wire – -454°F to 1600°F which is equal to -270°C to 870°C Accuracy (which will be greater) : Special limits of error – +/-1.0°C or 0.4% Standard – +/- 1.7°C or +/- 0.5 % Limitations : The sensitivity of thermocouple is comparatively small as compared to other types. This is so based on the reading of tens of microvolsts which are measured in ‘Celsius’. For better and clearer reading, you would need an offset amplifier, to read usable readings. You will surely need circuits or tables to measure things in better and efficient way. They have lower thermal mass. It may not read temperatures beyond 2300°C. The wires are well insulated and work efficiently. They are not insulated at the junction. If additional contacts are made or other objects are brought in between, it may affect the reading it finally gives. Benefits and Uses: Though there are multiple limitations with E-type thermocouple, yet they are worth use. The most commonly used sources, where such thermocouples are installed are:- Ovens Water Heaters Test equipments Many other industrial uses If want to give the order in bulk, so direct contact to the thermocouple manufacturers. Conclusion : While thinking of investing on thermocouples, for commercial uses, be easy as they are inexpensive and are interchangeable. They come with standard connectors. They are capacitated to measure wide temperature ranges. They are indeed very different than the other devices, used for measuring temperatures. They need not have an external or additional stimulant. Yes, temperatures may not be read accurately and readings are indeed compromised. But this limitation is based on the difference of one degree Celsius only. In spite of too much of criticism, thermocouple and its variants are still used. Apart from this, If you have any query regarding product, don’t feel shy to contact us in such cases. Product Details: Minimum Order Quantity: 6 PiecePower(Watts): As per requirement of applicationVoltage: As per requirement of applicationSize: As per requirement of application Features: High Temperature Resistant. Long Life. Cost Effective.

...more

Ceramic Heater Plate

Ceramic Band Heaters offers secondary heating for tanks, Right Around the peripheral of a drum or pipe,they warmth the surface of the vessel to make continuous, unvarying heat transfer. This technique is safe for usage of heating the volatile substances which are dangerous to heat via direct technique. Ceramic heaters are energy effective and offer elasticity for use in numerous applications. Designed for appropriate contact heating on cylindrical surfaces, electric ceramic heaters are fabricated by using excellent M.S. and stainless steel sheathing and brass. Furthermore, our range is also designed in perforated sheathing for the purpose of air-cooled application. Adding on, our gamut of mica, ceramic band heaters and nozzle heaters is covered with heat proofing pads to save energy. Wall heater is used for continuous heating solutions;ceramic heater element is frequentlystable on the walls and isextrainfluential than handy heaters. Ceramic heater plates are available in entirescopes & dimensionsdependent upon the size of room with the ceramic element in the middle.Compact Heaters are faultless for small homes and can be effortlesslytransported from one to another room owing to light weight and lessermass.

...more

CASTED NOZZLE HEATERS

Casted heaters/ Cast in Heaters The cast in aluminium heaters consists of the cast in elements which is embedded into single or multiple brasses, aluminium alloy, copper-nickel, iron-type material. Cast in heaters can be equipped with the sheath to ensure heating of pressurized gas and cooling by circulating water. Electric heaterare used for heating element, as well to maintain the shape of product. Casted heaters or casted aluminium heaters consist of following parts: Tube: protects resistance wire, shock protection and resistance to corrosion. Terminal connection: allow electrical connection of heating element and depend on current rating. Edge insulation: provide dielectric insulation The Seal: provide insulation against external moisture Output Rods: It is non-heating (CN) part of which section depends on current applied and diameter. Length is defined by the process. The Wire (Joule Effect): Nickel Chromium Alloy (80/20) Insulation: Compressed magnesium oxide to ensure good dielectric insulation and rapid heat transfer. Fastening device Application of Cast Heaters: Semiconductor processing Plastic processing cast in heaters packaging machinery Foodservice Paper processing medical equipment textile manufacturing heat transfer press Based on the application, cast in heaters/Cast heaters are further categorized into following sections: Cast in Heaters for Semi-conductor Processing: A line of the cast in aluminium and bronze alloys heater is manufactured to meet the requirement of semiconductor processing industry. Black platen heaters, bake/chill pedestal heaters, platen heaters, cast in hot chunk heaters, high-temperature platen heater and standard pedestal heaters. Cast in heaters for Plastic processing: Plastic processing application of cast heaters include Air Cooled Cast-in Barrel Heaters, Liquid Cooled Cast in Barrel Heaters, Air Cooled Cast In Heaters with Shrouds, L-Shaped Square Cast In Barrel Heaters, Vent Cut Out Cast in Heater, Heat-Only Cast-In Heaters, Hollow Cast Nozzle Heaters, Cast-in Cooling Jackets which provides effective heating and cooling for plastic extrusion barrel, sheath and corrosion protection. Cast in Platen Heaters: These platen heaters are used in heat transferring press, foodservice equipment, commercial pre-heaters, and die heaters. This platen heater consists of tubular heating elements and manufactured of aluminium or bronze alloys to provide maximum efficiency and temperature uniformity on working surface of the casting. Specification of Cast in Heaters: The temperature of the cast in heaters in Aluminium, brass, and copper-nickel can’t be more than 400°C (Max Wt.: 400 kg), 600°C and 650°C (Max Wt. 300 Kg) respectively. Finally, if you are looking to purchase cast in heaters, give your specification such as the seal type protective enclosure or ATEX, on request machining, insulation on request following temperature and ask for the quote. If all the things meet with your need, order cast in heaters. For any query regarding product, contact us without any shyness. FEATURES: –Complete foundry capabilities assure precise and uniform placement of the element in the casting. Our manufacturing plant assures quality management control from product design throughproduction and servicing. We produce castings with low porosity for better heat transfer. The system also minimizes internal voids and defects by precisely controlling molten metal temperature and feed rate. Optional cast-in tubing provides faster cooling or can be used to heat liquids or gases that run through it, functioning as a circulation heater. High thermal conductivity of aluminum provides extremely uniform surface temperatures to avoid damaging hot or cold spots when operating the heaters Product Details: Minimum Order Quantity: 6 PiecePower(Watts): As per requirement of applicationVoltage: As per requirement of applicationSize: As per requirement of application Specification: Liquid cooled or air cooled specification. Cast in material: Aluminum, Bronze or Iron. Largest possible diameter with maximum length steel sheath tubular heater to maintain good heater life.

...more

Cartridge Heaters

Cartridge heaters Cartridge heaters are the heavy duty tube-shaped Heating Elements which is used in heating industry process based on its intended application and requirement of specific watt density. Based on various properties of cartridge heater, it is divided into 6 categories out of which low-density cartridge heater is one of the product used for low density and limited temperature range of 400°C. Let’s check out the explanation of Low Density Cartridge Heater below: Cartridge heater are also called pencil heaters, electric heaters and bolt Heater. Electric heaters are used for heating element. Low Density Cartridge Heater: Low density cartridge heaters are made of helical wound nickel chrome resistance wire evenly stretched and placed in ceramic insulators. Remaining space of ceramic insulator is filled with high-grade magnesium oxide powder. This assembled element is inserted into Stainless steel 304/316/321, Brass tube. Normally, a Low-density cartridge heater is used in hot stamping, food processing machinery, medical equipment, Packaging Machinery, Rubber Manufacturing Process Machinery, Automobile Industries and mold & dies industry. Specification of Low Density Cartridge Heater: Max Operating Temperature: 400°C for SS 304 and 250°C for brass From diameter 8mm to 45mm and length 50mm to 3000mm Max surface load 4 watt/cm2 Nickel Chrome Resistance Wire Power 200W – 500W Application of Low Density Cartridge Heater: Hot Stamping Moulds & Dies Plastic Process Machinery Food Processing Machinery Medical and Packing Equipment Heating gases and liquids Labelling Machines Many more… Utilization of high-grade raw materials and modern machines is required to provide the best combination of resistance to heat oxidation and physical strength. If High purity magnesium oxide (Mgo) and specially selected grain size powder are used to fill the space then cartridge offers higher thermal conductivity, strength and long operating life of Cartridge Heaters. If you want to design or purchasing a Customised Low-Density Cartridge Heater, just tell us your requirement based on the application either you want cartridge heater for stamping or Electric Heaters for labelling machines, pencil heaters for blister Machines and get the quote. If you are going to buy such products from cartridge heaters manufacturers, then you should have provide the Wattage , voltage, diameter, length of Low density cartridge Heaters. Applications :- Plastic Processing Machinery. Moulds & Dies. Hot Stamping. Food Processing Machinery. Packing Equipment. Heating Gases & Liquids. Medical Equipment. Product Details: Minimum Order Quantity: 6 PiecePower(Watts): As per requirement of applicationVoltage: As per requirement of applicationSize: As per requirement of application Nickel Chrome Resistance Wire. Maximum Operating Temperature 250°C for Brass & 400°C for SS 304. Maximum Surface load 4 watts / cm2. Available From Dia. 8 mm to 45 mm & length 50 mm to 3000 mm.

...more

BTH Heaters

BTH Heaters BTH supplementary electric heaters are manufactured to conform the IPX4 rating and should be fitted only by the qualified electrician. BTH heaters are mostly used in the bathroom. According to I.E.E wiring regulations, the Electric heater must be earthed and connected to a cable outlet in the bathroom. This cable outlet should not be buried into walls and easy to accessible because it needs maintenance from time to time. It can be used for an industrial purpose such as oil and gas industry. Note: BTH Heaters shouldn’t be installed into the hot water domestic supply. Instruction to read before using BTH heaters: It is always recommended to install a return valve and return valve should be open whenever the supplement heaters are in use and radiator heats up, the volume of BTH heaters expand by 4%. Always remember to turn off the element before draining down a central heating system because if you don’t turn off the heater and the system is empty, the heater will overheat and blow its nonrepairable fuse. Always set a timer ON or OFF while using the central heating system and BTH heater simultaneously. Don’t use the central heating system and BTH heaters at the same time. If you do so, it will impact the working life of the supplementary heater. Types of BTH Heater: BTH Heater is available in BTH 300, BTH 400 and BTH 500 edition according to the National Standard for Gas-Fired Water Heaters. The requirement of BTH heater depends upon equivalent length, the number of appliances connected and the supply of gas line size and concentric termination. There is different-2 requirement of BTH for the vent or gas pressure with the type of gas either natural or propane gas. Features of BTH Heater: High efficiency Easy to install and operate Perfect finishing BTH Heaters are used where the outlet process temperature doesn’t exceed 87˚C. Application of BTH Heater: Hydrate Prevention To prevent freezing of expansion value in natural gas To enhance separation of efficiency Heating of crude oil to establish and maintain the temperature above the paraffin pour point. BTH heater is available into many models. Just check out the model which could full fill your requirement and then order it! Finally, if you have any question regarding BTH Heater, Thermocouples or any other related stuff, don’t hesitate. Just let us know your problem, question or suggestion and we will get back to you in no time. APPLICATION :- Air heating. Hotplates & Food processing machines. Ovens & Dryers. Air Ducts. Plastic Processing Machineries. Engineering Industry. Packaging Machinery. Shoe Making Machineries. Foundry Equipments. Radiant Surface Heating. Hot Runner Mould Systems. Product Details: Minimum Order Quantity: 6 PiecePower(Watts): As per requirement of applicationVoltage: As per requirement of applicationSize: As per requirement of application Water heating pipe. Pipe diameter are 6.6mm, 8.0mm and 10.0mm if a special diameter, the need for alternative. The surface load of the heating pipe is 9.8W/cm2. Voltage & Power: 110V-240V, 200W-20000W.

...moreBe first to Rate

Rate ThisOpening Hours