wire galvanizing plant

We are offering wire galvanizing plant. High hardened adjustable rolls. Shearing attachment (optional). Hand operated pointers are also available.

...more

Wire Drawing Machine

Machine is designed to operate continously. First block is provided oto type for wire accumulation,allwoing forthe removal of any rod,snarl or changeover of coils at feeding end. Vfn system on oto block keeps uniform tension of wire passing over with on jerks. Each block is equipped with pressure regulating valves and gauges for accurate control of air pressure on sensor arm. Separate maiflods are provided for water to drums and dies with regulating valve on each block.

...more

wet wire drawing machines

We are offering wet wire drawing machines description multi hold sub – merged type wet drawing machine designed for all ferrous & non – ferrous metals in the range of 911131519172125 dies or as per customer requirements with variable drives & speed.

...more

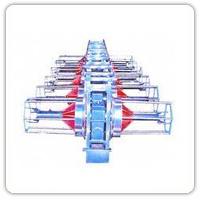

Tubular Strander

we offer tubular strander. we have an assortment of high productive skip stranders, that are widely used in manufacturing wires and conductor. these skip stranders have bobbin hold on bearing pintle, that provides smooth running. diameter compensating mechanical device keeps constant tension all along the process within the entire adjustable tension range. our range provides high speed process and is available in various specifications.

...more

Strand Annealing Furnace

We offer Strand Annealing Furnace. For H.S. & H.C. Steel wires electro & hot deep Galvanising plants ranging from 5mm to 0.4mm sizes with latest pickling system & feum extraction system.

...more

spooling machines

Vertical and horizontal Spooling Machines and a comprehensive range of coil winding machines that are used for layer winding of solenoids and bobbins. The range includes different types of machines having diversified specifications for winding speed, layer length, layer height, winding tension, pitch setting, coil weight etc. Collapsible bobbins for wire This bobbin is used to aid the coiling and packing of wire and strand. After winding the bobbin is dismantled for removal of the coil and packing. The bobbin is then easily reassembled with bolts to be reused. Removable parts allow for use with coils of varying width.B.B Block spooler Our organization specializes in offering a compact range of BB Block that is fabricated with calliper type pneumatically operated disc that helps to stop the machine once the breakage occurs. Qualified team members make sure to use qualitative raw material that is obtained from the credited vendors of the market. In addition to this, these blocks are available with us in diverse customized options as per their needs and demands.Some features are: Effective usage Low maintenance Resistance against corrosion Easy to install

...more

Skip Strander

we offer Skip Strander. We have an assortment of high productive skip stranders, that are widely used in manufacturing wires and conductor. These skip stranders have bobbin hold on bearing pintle, that provides smooth running. Diameter compensating mechanical device keeps constant tension all along the process within the entire adjustable tension range. Our range provides high speed process and is available in various specifications.

...more

OTO Wire Drawing

Each block is driven through heavy duty worm and wheel reduction gear box fabricated from steel plates. Drawing blocks are made of graded CL and metalized and ground on drawing portion to HR c 58 for good wear resistance. Block are designed for cooling by circulation of water internally and by air externally to attain good draw ability of wire. Dies are direct Water Cooled Dies boxes can be supplied with rotation die and lubricant stirrer. Die holders can be supplied to adopt pressure dies also

...more

Mechanical Descaler Machine

We offer mechanical descaler machine. Designed for descaling of m.s. & h.c. Wire rods with brushing installation to be installed in tendom with wire drawing machine for rod ranging from 5.5 to 10mm to avoid pickling treatment of wire rod & pollution free equipment.

...more

Flipper Payoff

Flipper PayoffTo feed the wire rod automatically in the machine without keeping man.Rotating payoff For non-stop operation of drawing machine. Designed for entanglement free feeding of wire rod to the machine, even at higher speed. Hydraulically operated tilting boom enables easy loading of wire rod. Option of former rotating system, to be synchronized with entry speed of wire drawing machine. Vertical column payoffThis unit comprises of two tilting coil holders and an overhead steel column with an integrated rod snarl protection system. The coil holders are hydraulically operated and lower to the horizontal position for coil loading. The coil holders then pivot through 90º to a vertical position for payoff. The vertical steel column within which is mounted a top pulley carriage and a bottom pulley carriage that is free to move vertically. The top carriage is moved down to its low position for threading up at floor level. For run position the carriage is moved and locked at the top. The bottom carriage is held in its lowest position by weights. In the event of a snarl the carriage is pulley upwards by the increase in wire tension and a limit sensor is activated thereby stopping the line.Motorized Horizontal PayoffMotorized smooth uncoiling of wire in synchronization with the Wire drawing machine operation.Accurately machined & supported with thrust bearings for robust support.Wire cage with wear resistant replaceable liners.S.R. PayoffWe offer wide array of S.R. Payoff, which are precisely designed and engineered with latest technologies. We ensure to deliver flawless range of products which are in compliance with the global standards. Our products are available in different shapes and dimensions and can be customized as per the requirement. S.R. Payoff machines are highly durable and authentic. Clients can avail this exclusive range in affordable rates. Features:Sturdy construction Robust design Durable Bobbin PayoffWe are one of the leading manufacturers and exporters of various engineering machines and equipments including Bobbin Payoff machines, which are made by using superior quality components and latest technologies. These Payoff machines are highly durable and long lasting, which make them widely demanded and praised among the customers. We ensure the customers with standard quality machines that are resistive to adverse conditions. Features: Resistant to rust Tensile strength highly durable Bronzing PayoffOur automatic pay off machines’ extensive range includes standard quality Bronzing payoff machines. These machineries are procured from our most trustworthy and authorized vendors in market. We are ensuring our esteemed customers by giving them easy to operate and dynamic functionality products. All these machines are made by superior quality components and effective material.Features: Easy to operate Automatic functionsDynamic operations TILTING PAYOFFWe supply a wide range of turn table payoff for wire coils from 25kg to 2500kg. Coils weights which are offered in powered and non-powered forms. The units are available for different drum diameter and loading capacities as well as adjustable friction brakes. We also undertake the designing and construction of custom payoffs.

...more

Dry Wire Drawing Machine

Machine is designed to operate continuously. First block is provided OTO type for wire accumulation, allowing forth removal of any rod, snarl or changeover of coils at feeding end. VFN system on OTO block keeps uniform tension of wire passing over with on jerks. Each block is equipped with pressure regulating valves and gauges for accurate control of air pressure on sensor arm. Separate manifolds are provided for water to drums and dies with regulating valve on each block.BLOCK AND COOLING SYSTEM: Drawing drums are forged alloy steel, fully hardened and ground. Surface hardness: 58-60 HRC. Drums are internally water cooled with narrow gap system. Complete wetting of wall by highly turbulent motion of water, higher cooling effect with increasing drawing speeds. Drums are externally cooled by air from a single common blower through duct forming part of machine frame.DIE BOXES: Dies are direct water cooled from a separate manifold. Dies are loaded from top for quick fixing. Motorized rotating die holders can be provided; extra long to adopt standard pressure dies. Die boxes are equipped with motorized lubricant stirrer. Rotating die holders have single motor for stirrer and holder. Die boxes are adjustable in horizontal and vertical plane for cast and helix adjustment of wire. Die boxes are suitable for dry lubricants, large enough to store sufficient quantity of lubricant.SPEED CONTROL: Speed regulation of each block is achieved through self cantering sensor arm on which the wire is guided.SAFETY GUARD: Well balanced sheet metal guards, with transparent sheet/wire mesh to see through condition of machine, are provided. Guards are electrically interlocked not to allow running of machine with open guards. Sound proof guard for low noise level with suction of burnt powder can be provided.TRANSMISSION: Motion transmission from motor to block shaft is achieved directly by V belt and pulleys or through helical gear arrangement.INTELLIGENT CONTROLS: Specially designed A.C. Three Phase Inverter Duty/Servo Motors L&T Supernova/Siemens 1ph7 constant torque up to base speed and constant power above base speed. Digital A.C. Three Phase Vector Flux Inverter Drives ABB ACS 800/Siemens Kinemics provide the system with fastest communication through provirus. All blocks are working with a range of encoder feedback, thermal protection, and flux vector controlled. The logic control is attained automatically by PLC system (Siemens) automatically calculating reduction rate and monitoring all related dates.Utmost control flexibility allows any drafting programme and drum skipping. HMI displays all function data making it easier for the operator to take control of the machine during production. Displays and memorizes the fault for easy diagnosis. Can be interfaced with remote computer to collect all information. Cubicles are sheet steel enclosures with IP54 protection, duly power coated and with exhaust. Electric control system provides a smooth acceleration from zero to pre-selected value. Normal stop is attained with ramp down control within 15 to 30 second. Emergency stop/quick stop is attained within 6 to 8 seconds. This can be achieved without a broken wire.

...more

dead block coiler

Available in the range 300mm to 900mm for heavy coils with pattern lay arrangement & continues run of the machinery viewing 95% efficiency of Wire Drawing Machines.

...more

Bull Block Machines

Vertical - horizontal & gravity bull blocks with multi speed & variable drives Suitable for ferrous - non ferrous wire ranging from 6mm to 25mm inlets & models of 750mm /900/1000/1200mm dia coils.

...more

Furnaces

Rolling Machines

Be first to Rate

Rate ThisOpening Hours