Filter Press

Get Price Quote

1 Piece(s) (MOQ)

We are the most trusted Filter Press Manufacturer, supplying a wide range of Dewatering Filter Press. Dewatering Filter Press is one of the most efficient sources to separate liquid and solids by pressure filtration for the solution filtration, sludge volume reduction, or any other. Dewatering Filter Press provides a simple, reliable method of high compaction pressure to compress and dewater solids into cakes of 25 - 60% total concentration, producing clearer filtrate solutions than systems, which remove only free water. For supplying the durable Dewatering Filter Press, we have been chosen as the prime Industrial Filter Press Supplier in India. Available sizes (in mm) 300 x 300 450 x 450 610 x 610 765 x 765 915 x 915 1000 x 1000 1200 x 1200 Technical data required Type of Frame Type Plate Shifting Type Delivery Washing Closing Devises Construction Material of Filter Element Types of Filter Press Working Pressure Plates Drainage Surface Filter Media Used Typical Applications Process Filtration Pharmaceuticals and Chemicals Clarification of Processed Fluids Municipal Sludge Dewatering Reduction of Waste Solids Precious Metal Recovery Biological Filtration Food Processing Saline Filtration

Hydraulic Filter Press

Get Price Quote

Best Deals from Cast Iron Filter Press

Filter Press Machine

Get Price Quote

5 Piece (MOQ)

filter press panels

Get Price Quote

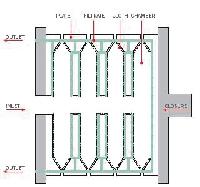

Filter press panels were introduced at the roll of the century and have been in the order of for many years. A filter press contains a sequence of plates with a filtering surface on both sides. The plates are enclosed with a Filter press panels cloth. Numerous of these plates are pushed mutually to form chambers with adequate Filtration area for the application. Slurry is forced into the chamber. The press cloth allows the filtrate to go by through, watering the filter cake which gets formed on the press cloth. The cake is discharged by pulling the plates apart. This cycle then repeats itself. Filter presses are among the most multipurpose of all liquid/solid separation unit operations. They become accustomed easily to variations in feed concentrations, constituent part size and other substantial properties, delivering very dry cake and high solids capture with low chemical conditioning expenses. Features Amrit Filtration Equipment’s manufactures all styles of press cloths including drape-over, CGR, and cloths with connecting sleeves (butterfly types). We provide head, tail, and intermediate press cloths in various medias and designs including plain cloths, and center and corner feed holes. We also offer covering cloths in many different styles and configurations. Available in cotton, polyester, polypropylene, nylon Drape-over & Butterfly Thermal cut panels Velcro fastening for easy fixing Unique neck fabrication Metal & plastic eyelids for holes Benefits with Amrit Excellent cake release Good particle retention Easy installation Custom made for every application Long life at an economic price

Automatic Filter Press

32,000 Per Piece

1 Piece(s) (MOQ)

We are supported by a team of quality auditors who make sure the product compliance in tune with the set quality standards. Our products are subjected to the payment terms & conditions of our company. Patrons are provided with the terms & conditions, and can make purchases with a payment method best suited for them.

Oil Filter Press

Get Price Quote

Being a notable enterprise of this industry, we are offering a wide range of high quality Oil Filter Press. Suitable for clearing and filtering the different plant crude-oil, provided filter press is manufactured using high grade material in line with the set quality standards. We offer this filter press in numerous specifications and can be customized too as per the needs of our clients.Features: High oil filtering rate Noise less performance Low electricity consumption

Filter Press

Get Price Quote

We offer Filter Press for various applications in cast iron filter press, recess filter press, membrane filter press, wooden filter press and PP filter press. Fabricated using quality material, the product is durable, reliable and highly efficient. The range is checked on stringent quality parameters to ensure good filtration efficiency, temperature resistance and longer service life. The filter press is applicable in areas like pesticides, food and beverages, pharmaceuticals, agro chemical plants and ceramic industries.

Membrane Filter Press Plates

Get Price Quote

Filter Press-02

Get Price Quote

We offer Filter Press

Sparkler Filter Press

Get Price Quote

The filter cartridge assembly inside the shell consists of several vertically arranged disc type filter plates with perforated supporting screens, filter media & interlocking cups. The entire assembly complete with pump & piping connection is mounted on a suitable S.S. Trolley. The impure liquid to be filtered is fed to the filter shell by pump. It arrives on top of each plate through opening on the sides of plates. As liquid pressure increases, the filter media (Paperfabric) holds back the impurities & allows the crystal clear filtrate to pass through the central channel (formed by interlocking cups) which takes the filtrate to the outlet of filter. This filter most commonly used to obtain clear liquid. However if required, the cake formed between the plates can be obtained. Filtration is continued until its rate becomes very slow due to increased cake resistance.

Sparkler Filter Press

Get Price Quote

It is a sparkler type and consist of S.S. Shell & Top cover using bolts to give pressure tight enclosure. The filter cartridge assembly inside the shell consists of several vertically arranged disc type filter plates with perforated supporting screens, filter media & interlocking cups. The entire assembly complete with pump & piping connection is mounted on a suitable S.S. Trolley. The impure liquid to be filtered is fed to the filter shell by pump. It arrives on top of each plate through opening on the sides of plates. As liquid pressure increases, the filter media (Paperfabric) holds back the impurities & allows the crystal clear filtrate to pass through the central channel (formed by interlocking cups) which takes the filtrate to the outlet of filter. This filter most commonly used to obtain clear liquid. However if required, the cake formed between the plates can be obtained. Filtration is continued until its rate becomes very slow due to increased cake resistance.

Filter Press Machine

48,000 Per Piece

oil filter presses

Get Price Quote

Oil Mill Spares Parts

Filter Press

Get Price Quote

Oil Filter Press

Get Price Quote

Oil Expeller Spares, expeller parts, Oil Filters

Belt Filter Press

Get Price Quote

It is widely used in the sludge dewatering of city waste water treatment plants, textile dyeing, electroplating, papermaking, leather, brewing, food processing, coal washing, the petroleum chemical.

Oil Filter Press

Get Price Quote

For Oil, Sugar, Chemical & Water Treatment Plants1. All the plates, frames & stands are casted from heavy duty close grained castiron.2. The faces of the plates and frames are accurately machined and ground to avoid any leakage.3. The plates and frame rest on heavy type steel plates. The frame is very rigid and durable and can stand very high pressure.4. The tightening screw is made from solid steel and has course pitch square threads for quick opening and closing of press.5. Heavy type plunger pumps in various sizes fitted with gun metal valves are provided for twofold purpose, filteration as well as delivery.

Filter Press

Get Price Quote

dust collection bag, Saff Media, Fine Bubble Disc Diffuser

Filter Press for Sludge Dewatering

Get Price Quote

Filter Press for Sludge Dewatering, Decanter Centrifuges

Filter Press

Get Price Quote

hydraulic wax press, sugar mill machinery parts

Filter Press

Get Price Quote

Filter Press

Get Price Quote

Dosing Pump, Screw Press

Cast Iron Recessed Filter Press

Get Price Quote

Cast Iron Recessed Filter Press

Filter Plate

Get Price Quote

Oil Filter Press

Get Price Quote

sponge iron plant, Intermediate Mill Stand, Rolling Mill Stands

Filter Press

Get Price Quote

Filter Press

Get Price Quote

Membrane Diffusers, Gears, Engineering Equipment, auxiliaries