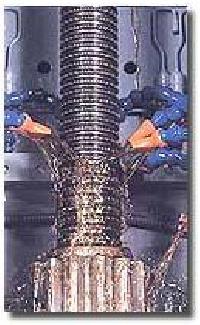

CNC Fettling Machine

Get Price Quote

1 Piece (MOQ)

These machines are suitable for fettling of Aluminum Die Cast, Cast Iron & steel casted components to remove the parting line & gate cutting application specially designed for mass production. These machines are having the facility to do multiple operations in single setup. The machine can be programmed as per customer fettling requirement. The machine having multiple servo axes to facilitate the fettling operation at different sizes & angles. These machines are having direct drive spindle unit with 180 deg. rotation. The machine is also having the combination of spindle units to hold the different tools. Features: Reduction in cycle time Higher Productivity Easy Programmable Minimize the flow of parts on shop floor Reduction in floor area. Applications: Aluminum die casted components C.I. Casted Components Cylinder Head Cylinder Block Crank Case Crank shaft Cam shaft Exhaust manifold Fuel pump body

garment finishing machine

7,000 Per Pair

Best Deals from Finishing Machine

surface broaching machine

900,000 Per Piece

v notch broaching machine

Get Price Quote

Chamfering Machine

Get Price Quote

Our manufactured Chamfering Machine is engineered using the high grade of raw materials and components with the help of our state of the art infrastructure and our technically skilled staff. We not only manufacture but also supply them to our valued patrons in a timely manner and at the most competitive market price.

surface broaching machine

800,000 Per Piece

Broaching Machines

Get Price Quote

We are offering broaching machines. In the age of global competition, there is more attention towards the automation by way of machining centres and multi-function turning centres. Broaching has the positive advantages like high productivity and repeatable product quality. Broaching machineproductivity improvement to ten times or even more is not uncommon, as the speed of metal removal by broaching is vastly greater. Roughing, semi finishing and finishing of the component is done just in one pass by broaching, and this pass is generally accomplished internal broaching machinein seconds. Thus broaching has proved to be a most simple, highly productive cost effective and practical machining operation. It requires lesser manpower, extending its use in wide fields of applications with exceptional savings on machine and tooling cost. Broaching is highly productive metal cutting process, in which the metal is removed by successive action of number of cutting teeth incorporated in the tool called broach. Broaching is a significantly superior process having certain positive advantages like: short cycle time with high accuracy. Complicated irregular shapes can be easily cut. Remarkably stable process accuracy. Superior finished faces. Extremely economical.

surface broaching machines

Get Price Quote

Used Tooth Chamfering Machine

251,000 Per Number

Broaching Machines

Get Price Quote

In the age of global competition, there is more attention towards the automation by way of machining centres and multi-function Turning centres. Broaching has the positive advantages like high productivity and repeatable product quality. Broaching machineProductivity improvement to ten times or even more is not uncommon, as the speed of metal removal by broaching is vastly greater. Roughing, Semi finishing and finishing of the component is done just in one pass by broaching, and this pass is generally accomplished Internal Broaching Machinein seconds. Thus Broaching has proved to be a most simple, highly productive cost effective and practical machining operation. It requires lesser manpower, extending its use in wide fields of applications with exceptional savings on machine and tooling cost.

Broaching Machine

600,000 Per Piece

Hydraulic Broaching Machine

Get Price Quote

In the age of global competition, there is more attention towards the automation by way of machining centres and multi-function Turning centres. Broaching has the positive advantages like high productivity and repeatable product quality. Productivity improvement to ten times or even more is not uncommon, as the speed of metal removal by broaching is vastly greater. Roughing, Semi finishing and finishing of the component is done just in one pass by broaching, and this pass is generally accomplished Internal Broaching Machinein seconds. Thus Broaching has proved to be a most simple, highly productive cost effective and practical machining operation. It requires lesser manpower, extending its use in wide fields of applications with exceptional savings on machine and tooling cost.

surface broaching machine

Get Price Quote

Broaching Machines

Get Price Quote

Broaching Machines, Press Brake Machines, Spline Milling Machine

Broaching Machine

Get Price Quote

Broaching is a machining method in which a series of cutting teeth each remove a portion of stock as the cutting tool (broach) moves past or through the work piece. Combining both roughing and finishing in one operation Broaching removes stock to precise tolerance faster than any other known metal cutting process. Broaching is highly productive Metal Cutting Process, in which the metal is removed by successive action of number of cutting teeth incorporated in the tool called Broach.The broaching process, similar to shaping with multiple teeth, is used to machine internal and external surfaces such as holes of circular, square, or irregular shapes,keyways and teeth of internal gears. A broach is a long multi-tooth cutting tool with successively deeper cuts.Broaching is a significantly superior process having certain positive advantages like: • Short Cycle Time with High Accuracy. • Complicated irregular shapes can be easily cut. • Remarkably Stable Process Accuracy. • Superior Finished Faces. • Extremely Economical. Types Of Broaching Machines: • Vertical Internal Pull Down Broaching Machine. • Push Type Broaching Machine. • Horizontal Broaching Machine. Range Of Manufacturing: • Capacity – 1ton to 30 ton. • Stroke – 450mm to 2000mm. • Cutting Speed – 5 to 10 m/min. • Return Speed – 15 to 30 m/min.

Glass edging machine

Get Price Quote

Super Finishing Machine

Get Price Quote

robotics automation, pencil making machine, Vertical Balancing Machine

Hurth ZK10

Get Price Quote

Hurth ZK10, gear grinding machine, gear shaver, CIMA CNC Hobbing Machine

Broaching Machines

Get Price Quote

Broaching Machines, Hydraulic Presses, Accumulators, powerpacks

Broaching Machine

Get Price Quote

Broaching Machine, machine refurbishment service, spm automation

Broaching Machine

Get Price Quote

Broaching Machine

Broaching Machine

Get Price Quote

Broaching Machine, WASHING MACHINE

Glass edging machine

Get Price Quote

Glass edging machine, glass bending machine