TEJAS-R DIRECT REACTIVE TEXTILE PRINTER

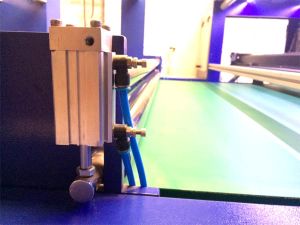

TEJAS Series is most highly rated product series in the country and worldwide. It comes with 4, Japanese Micro Piezo print Epson DX 5 heads- with 8 color option which is one of the best printing solutions for textile printing. You can fabricate Cotton, Polyester and blends. With the industrial belt system, we have configured it with the best engineering technology available now. HDMI operation gives you the ONE TOUCH operating to maximize your production. Its automatic washing unit, with 2 sponge rolls and 1 brush rolls, make this machine GEM of the textile printers. Technical Advancement:- 4, Japanese Micro Piezo print Epson DX 5 heads 8 color option which is one of the best printing solutions Automatic washing unit, with 2 sponge rolls and 1 brush rolls HDMI Operating:- High quality graphics for realistic representations. High complex feeds available in effortless appearance with applications movement Feeding Unit:- 90 Kg bearable point to support roll to roll printing. Helps to reduce human interface. Specification:- Model HGS-DIR-4PS (TEJAS - R) Printing Technology Epson DX5 Micro Piezo, Drop on demand Print Head No. No. Resolution Height 2 720 dpi, 1080 dpi, 360dpi Adustable Ink Reactive, Acid, Disperse, Pigment (With 8 colors) Printing Width 1800mm

...more

HURRICANE DIRECT REACTIVE TEXTILE PRINTER

DIGITAL TEXTILE PRINTER Hurricane is our new product going to launch worldwide. High production, low consumables and repairing cost, high standard printing and most economical in its class. The HGS-DIR-8 PS “Hurricane” Printer is designed for high speed textile printing, sampling and mass production printing. Starfire 1024 10 PL:- Single-color operation at 400 dots-per-inch from 1024 independent channels. Average life 2.6 month. Removablereplaceable coated metal nozzle plate. 10 PL nozzles. Continuous ink recirculation at the nozzle. Conveyor belt system:- Conveyor belt compatibility with any configured printer with speed up to 400 Sqr.Hr. 3 phase Printing individual process. Position HMI Controlling:- 1 (10” Omron) & 2 (7 ” Omron ) HMI Placed at Feeding, Printing & Heating Units. High quality graphics for realistic representations of machinery and processes. Technical Advancement:- Separate unit of Take –up & Feeding. Auto belt drying Unit in down side to keep belt dry always. Pneumatic controlled washing unit with 3 Sponge rolls and brush roll. Software Printing Quality:- Compatibility with World Most Advanced Software “Neostampa & RIP Master” 720 DPI | 1080 DPI | 900 DPI| 360 DPI. Specification:- Model HGS-DIR-HURRICAN Printing Technology Starfire 1024, 6pl, Drop on Demand Print Head No. No. Resolution Height 8 Single color Operation upto 400dpi Auto Adustable Ink Reactive, Acid, Disperse, Pigment (With 8 colors) Printing Width 1828mm

...more

digital textile printing

fabric dying

Fabric Processing

Textile School

Fabric Shop

Interior Fabric Printing

Fashion Fabric Printing

Bulk Fabric Printing

textile printing

Be first to Rate

Rate ThisOpening Hours