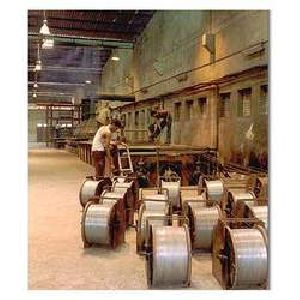

Hot Dip Wire Galvanizing Plant

Get Price Quote

We are engaged in manufacturing and supplying wide range of Hot Dip Galvanizing Plant to our clients. These products are manufactured using high quality basic material, procured from the trusted vendors of the market. Professionals of our team have manufactured these products in complete compliance with international standards of quality. These are widely demanded by our clients for their sturdy construction, excellent durability and reliable performance. Clients can avail these at affordable prices.

Pit Pot Type Annealing Furnace

Get Price Quote

We hold expertise in offering a wide assortment of Pit Pot Type Annealing Furnace to our clients. With the help of our experts, we offer our range in different specifications that meet the individual requirement of our clients.

Best Deals from Industrial Furnace

Industrial Gas Burner

30,000 Per Set

Heavy Oil Burner

Get Price Quote

Two Stage Operation / Press 30·45·60·100 N Series This series of fuel oil burners comprises of four models with firing rates from 168 to 1120 kW and has been specifically developed to serve moderately pressurized or negative draft applications. Offering low fire start or two stage operation, the burners are designed for use with fuel oil upto 3.5°E but the 60N and 1 OON models can be adapted for use with heavier grades- upto a maximum of 65°E at 5CfC

Lead Refining Kettle

Get Price Quote

Based in Uttar Pradesh, we are emerging as one of the leading Manufacturers and Suppliers of Lead Refining Kettle that has been in wide demand due to its exceptional features. The Lead Refining Kettle range that we deal in includes Lead Melting Pot & Alloy Pot and Lead Discharging Pump. Manufactured with utmost precision, these Lead Refining Kettles, Pumps and Pots are made of the best quality raw material to produce the best quality outputs. An extended overview of Lead Refining Kettles has been provided below : Secondary Lead Recycled from used Lead Acid Batteries consists of & many impurities like (S, Cu, Ni, As, Sb, Bi, Ag, Au, etc.) The removal of all these impurities from Crud Lead is called Lead Refining. Lead is refined with a minimum purity of 99.97% for the further utilization. CGIT provide Lead Refining Kettle Furnaces of various capacities ranging from 5 tons to 50 tons per batch. The emission and smoke / Gases exhausted from the kettle are passed through a hygienic hood, further connected to the wet scrubber, chimney and suction blower through pipe ducts. Lead Refining process is done by melting Crud Lead Ingots in a Refining Kettle duly heated by either LPG Burner or Furnace Oil Burner. The temperature is raised approximately up to 327ºC to 650ºC. The chemical reactions are then made by the adding of specific reagents into the molten Lead at proper temperatures. These chemical reagents help to remove the impurities present in the crud lead. Generally Copper (Cu) is the first element which is removed in the form of Copper Sulphide by adding Sulphur. The temperature is raised up to 450ºC and required amount of Sulphur is added in the Kettle which removes all most all of the Copper. Once again some amount of Sulphur is added to remove the remaining Copper if required until no more reaction takes place. The second step is taken to remove Tin (Sn) in the form of Tin Chloride by adding Chlorine or Ammonium Chloride at a temperature of 500ºC. Thereafter temperature is again raised up to 550ºC to remove Arsenic (As) and Antimony (Sb) by oxidation process or adding a mixture of Sodium Nitrate & Sodium Hydroxide. After removing all the impurities from molten Lead the final Lead Sample is examined to discharge it either manual Ingot Casting or on automatic Lead Ingot Castor Machine with a capacity of 10 to 20 metric tons / hour.

Burnout furnace

Get Price Quote

Rolling Mill Reheating Furnace

Get Price Quote

We are engaged in offering well-designed Rolling Mill Reheating Furnace. The Rolling Mill Reheating Furnace is manufactured using technologically advanced machinery, ensuring high international standards. Strict adherence to optimum quality is maintained throughout the production of the Rolling Mill Reheating Furnace. The Rolling Mill Reheating Furnace can be availed at the market leading prices from us. Attributes Robust constructionLong service lifeHighly efficientConsistent performance

Discharging Ejector

Get Price Quote

Discharging Ejector Is An Electro-Mechanical Device Which Is Used To Expel The Hot Material From The Re-Heating Furnace To The Rolling Mill. It Has A Mill Housing Type Structure With A Movable Frame And Can Do Both Front And Side Travel For Discharging Of Hot Material(Like Ingots, Billets)From Re-Heating Furnace. It Comes Complete With Heavy Stand, Rollers, Cooling System, Wheel For Cross Travel, Gear Box, Pushing Arrangements Etc. It Uses A Square Billet Of Approx.6 Meters(Or More)Length As The Device To Push The Hot Material Out Of The Re-Heating Furnace. It Is Manufactured Depending On The Size And Capacity Of The Re-Heating Furnace.

induction heating furnace

100,000 Per Piece

Melting Furnace-Copper

Get Price Quote

MELTING FURNACES, STORAGE TANKS, ROLLOR CONVEYORS, SCREW CONVEYORS, BURNERS, SPINNER MACHINES,GAS MANIFOLDS,OVAN SLATT CONVEYORS, BELT CONVEYORS, LPG RING BURNERS, BURNER MANIFOLDS, RUBBERISED ROLLS, BLOWERS, ID FANS, OVAN CONVEYORS, CHAINS, SLATTES, CHAIN (HD), IMPLELLORS, CHIMNEYS,VESSELS, REACTORS,EJETATORS, MIXER, MIXING VESSELS ETC.MOC: STAINLESS STEEL, MILD STEEL, COOPER, ETC.

Hot Dip Galvanized Wire Plant

Get Price Quote

Assomac group provides its customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups. By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for Galvanizing of High Carbon and Low Carbon Steel Wires. Assomac has become the pioneers in supply of turnkey projects for the wire industry; we will maintain this position trough reliable equipment and service to our customer's world wide. The plant consists of the following : Pay Off Stands: Revolving Turn Tables with brake tensioners for wire formers and spools, overhead coil opener type Pay Off, Pintal Type Pay Off for Spools and Basket Type Pay Off for Coils. Open Hearth Furnace or Lead Bath Furnace with electric heating or Natural gas/LDO/FO combustion systems with top cover and recuperator for energy conservation. Online Fumeless Pickling System with water curtains to prevent any acid fumes form exiting the pickling system. The wires travel straight with lower tension and react with invigorated acid traveling against the wire, followed by triple stage water wash system. Intermediate wiping system in between chambers to prevent excessive carry over of fluids from one chamber to another. Vertical Gland / Seal Less Pumps for zero down time as no seal change over and routine maintenance required. Stainless Steel SS-316 fabricated Flux Tank with flue gas heating and temperature control system for energy efficiency and coating consistency. Option of Dipping type or straight path type with flux pumping system. Flux Dryer before the entry to the galvanizing bath hot plate assembly is provided for quick drying of flux which has heating through flue gases of the zinc bath furnace as rising energy costs has made conservation a prime criteria in today's plants. Zinc Bath furnace consisting of Structural Steel Frame which is completely lined using several layers of ceramic refractory. Best quality refractories ensure reliability and durability. Zinc Tank made out of low carbon low silicon steel plate with side bended at 90 degree welded with specialized electrodes and duly ultrasonic tested for any internal cracks. Options for light / medium and heavy coating available. Zinc coated control through pad wiping, spring wiping for low & medium coating & vertical charcoal or nitrogen wiping for heavy coating can be provided. Finally wire is coiled on finishing Take ups where ASSOMAC offers several options depending on the industry use and coil weight requirements right from 25Kg. to 1000Kgs. Horizontal side winder take ups, Vertical drop coiler with or without pattern lay and strip take ups in our manufacturing programe.

wire galvanizing plant

Get Price Quote

wire galvanizing plant, wire drawing plant, MIG Wire Plant

Industrial Furnace

Get Price Quote

Industrial Furnace, MS TANK VERTICAL, Fabrication Services

galvanising plant

Get Price Quote

We feel enough pleasure and pride to introduce ourselves as the leading growers, dealers and exporters of galvanising plant in India.

Galvanizing Plant

Get Price Quote

Galvanizing Plant, Furnaces, power cable machinery, Wire Drawing Machines

Hot Dip Galvanizing Plant

Get Price Quote

Hot Dip Galvanizing Plant, Industrial Chemicals, Water Treatment Chemicals

Galvanized Wire Plants

Get Price Quote

Galvanized Wire Plants, Binding Wire System, Wet Wire Drawing Machine

rotary furnaces

Get Price Quote

rotary furnaces, industrial fan, Air Compressor Tank, Axial Flow Fan

Forging Furnace

Get Price Quote

Forging Furnace, Forged Flanges, Forged Rings, forged rounds, Forged Shaft

wire galvanizing plant

Get Price Quote

wire galvanizing plant, Strand Annealing Furnace, Vertical Drop Coiler

Hot Dip Galvanizing Plant

Get Price Quote

Hot Dip Galvanizing Plant, Graphite Block Heat Exchanger, Frp Lining Tanks

Tyres For Kilns Ball Mill

Get Price Quote

Tyres For Kilns Ball Mill, Hydro Turbine Rotor Shaft, non standard forgings

Pit Pot Type Annealing Furnace

Get Price Quote

Pit Pot Type Annealing Furnace, Strand Annealing Furnace

Billet Reheating Furnace

Get Price Quote

Billet Reheating Furnace, Mill Stand, hot saw, Grip Tilter