Kiln Tyre

48,000 Per Piece

1 Piece (MOQ)

Gas Burner

Get Price Quote

1 Piece(s) (MOQ)

We are specialized in offering our clients a broad assortment of excellent quality Gas Burner. Oxilon Gas Burner is designed with high precision in compliance with international quality standards using optimum quality components.

Best Deals from Industrial Furnace

Muffle Furnace

Get Price Quote

We make available Muffle Furnaces which are acclaimed for their sturdy make. With strong industrial experience, we make sure that the packaging is done as per the stated norms, by this; the products that we deliver are absolutely safe from the getting damaged. Our company is one of the dependable providers of premium range of our product in Ghaziabad(India).

Pellet Burner Machine

Get Price Quote

1 Piece (MOQ)

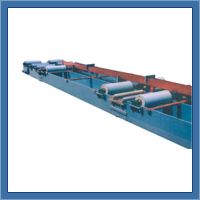

wire galvanizing plant

Get Price Quote

We hold expertise in manufacturing and supplying an exclusive range of Wire Galvanizing Plant. These products are fabricated using superior grade factor inputs, sourced from the reliable and certified vendors of the market. Our product range is extensively used for various industrial purposes and is widely appreciated by our clients due to its durable finish standards, high tensile strength and reliability. Our valuable clients can avail these products from us at the most affordable rates. The use of inverted vertical drawing machine is increasing day by day for drawing cold heading quality wire, high carbon wire, stainless steel wires & various kinds of alloy wires of thick sizes and specially for small quantity each sizes with bigger coil weights. The machine can increase the efficiency of work to a large extent as the drawing is done from coil to coil & drawn wires are directly wound on carries with are taken as it is for further in plant use or large coil despatches.In case of wires size over 20mm productivity can also be increased with inline type cutter pointing machine and horizontal arm type revolving pay of with push feeding system.

Biomass Pellet Burner

25,000 - 350,000 Per Set

2 Set(s) (MOQ)

monolithic burner blocks

Get Price Quote

With the assistance of our reliable transportation facilities, we have become capable of delivering the orders on time. The offered lot is precisely manufactured using superior grade material and in conformity with the industry standards.

Diesel Furnace

200,000 Per Piece

1 Piece(s) (MOQ)

40" diesel furnace ,all snack item frying auto temprature controller and good quality SS 304

Muffle Furnace

Get Price Quote

1 Piece (MOQ)

Wire Galvanising Plant

Get Price Quote

1 Container (MOQ)

Industrial LPG Gas Burner

Get Price Quote

Available in diffrent models, our Industrial LPG Gas Burner has output varying from 11 kw to 220 kw. Only after getting approval from the quality experts, we make use of the inputs sourced from the vendors. We make sure that our entire range is of excellent quality and faultless. Being a prominent name in this area of operations, we, as a Supplier, bring forth qualitative array of Industrial LPG Gas Burner.

Discharging Ejector

Get Price Quote

Discharging Ejector Is An Electro-Mechanical Device Which Is Used To Expel The Hot Material From The Re-Heating Furnace To The Rolling Mill. It Has A Mill Housing Type Structure With A Movable Frame And Can Do Both Front And Side Travel For Discharging Of Hot Material(Like Ingots, Billets)From Re-Heating Furnace. It Comes Complete With Heavy Stand, Rollers, Cooling System, Wheel For Cross Travel, Gear Box, Pushing Arrangements Etc. It Uses A Square Billet Of Approx.6 Meters(Or More)Length As The Device To Push The Hot Material Out Of The Re-Heating Furnace. It Is Manufactured Depending On The Size And Capacity Of The Re-Heating Furnace.

Rotary Smelting Furnace

Get Price Quote

We are a well-established name as Rotary Smelting Furnace Manufacturer and Supplier in Uttar Pradesh, India. We provide Rotary Furnace for Lead Smelting. The Lead Smelting Rotary Furnace is a mechanized furnace, Round Shell with both ends conical. Conical ends are open on both the sides. Rotary Furnace works in a batch process. Raw material is charged from one end along with certain chemical and additives like coke breeze, cast iron chips, soda ash etc. Rotary Smelting Furnace that we provide is designed by the experts using the latest production techniques. Rotary Smelting Furnace is heated with the help of Burner which uses oil or gas as a fuel. The Furnace is heated continuously and also kept rotating at very low speed of up to 1 to 1.5 RPM. Rotary Furnace rotates with the help of tyres around the furnace shell mounted on four roller wheels. These Roller wheels are fixed on a MS structure frame duly fitted in Bearing & Bearing Blocks. Wheels are driven first with the help of Electric motor coupled with Speed Reduction Gear Box & driving shafts, which rotates the furnace shell also. Furnace Shell is lined with CFK or HFK Insulation Bricks and High Alumina 70% refractory fire bricks. Both conical ends of the furnace are open. The front end of the furnace is used for the charging of raw material as well as heating with the movable burner. Burner is shifted aside at the time of charging raw material along with additives & then again moved at the mouth of the furnace for heating & melting of the scrap. Furnace is rotated for the proper mixing and reaction of the additives and as the Lead metal in molten state occurs, it is discharged into the moulds from the Taping Hole provided at centre of the furnace. After draining the Furnace of the first batch, production of next batch is undertaken and the Furnace is again charged with raw material. After three such batches, one batch of slag collected in Rotary Furnace is executed. Processing in the furnace is done at high temperatures and therefore it is operated continuously for long periods of time. It is used for production of large quantities and need skilful handling & maintenance. The smoke & gases are exhausted from the back conical end of the furnace attached with connecting duct to the Air Pollution Control System. We manufacture Rotary Furnace Plant for a production capacity of 2 metric tons to 25 metric tons of production per day. The Salient Features Of Our Rotary Furnace Plant With APC Are Low fuel consumptionLong refractory lining lifeReduced initial heating timeGives more number of batches per shiftRecovers maximum lead in the first operationSlag produced is lead free Note : Equipment can be scaled up for higher production capacities.

Pit Pot Type Annealing Furnace

Get Price Quote

We hold expertise in offering a wide assortment of Pit Pot Type Annealing Furnace to our clients. With the help of our experts, we offer our range in different specifications that meet the individual requirement of our clients.

Fluidized Bed Cleaning Furnaces

3,100,000 Per Onwards

induction heating furnace

100,000 Per Piece

Hot Dip Galvanized Wire Plant

Get Price Quote

Assomac group provides its customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups. By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for Galvanizing of High Carbon and Low Carbon Steel Wires. Assomac has become the pioneers in supply of turnkey projects for the wire industry; we will maintain this position trough reliable equipment and service to our customer's world wide. The plant consists of the following : Pay Off Stands: Revolving Turn Tables with brake tensioners for wire formers and spools, overhead coil opener type Pay Off, Pintal Type Pay Off for Spools and Basket Type Pay Off for Coils. Open Hearth Furnace or Lead Bath Furnace with electric heating or Natural gas/LDO/FO combustion systems with top cover and recuperator for energy conservation. Online Fumeless Pickling System with water curtains to prevent any acid fumes form exiting the pickling system. The wires travel straight with lower tension and react with invigorated acid traveling against the wire, followed by triple stage water wash system. Intermediate wiping system in between chambers to prevent excessive carry over of fluids from one chamber to another. Vertical Gland / Seal Less Pumps for zero down time as no seal change over and routine maintenance required. Stainless Steel SS-316 fabricated Flux Tank with flue gas heating and temperature control system for energy efficiency and coating consistency. Option of Dipping type or straight path type with flux pumping system. Flux Dryer before the entry to the galvanizing bath hot plate assembly is provided for quick drying of flux which has heating through flue gases of the zinc bath furnace as rising energy costs has made conservation a prime criteria in today's plants. Zinc Bath furnace consisting of Structural Steel Frame which is completely lined using several layers of ceramic refractory. Best quality refractories ensure reliability and durability. Zinc Tank made out of low carbon low silicon steel plate with side bended at 90 degree welded with specialized electrodes and duly ultrasonic tested for any internal cracks. Options for light / medium and heavy coating available. Zinc coated control through pad wiping, spring wiping for low & medium coating & vertical charcoal or nitrogen wiping for heavy coating can be provided. Finally wire is coiled on finishing Take ups where ASSOMAC offers several options depending on the industry use and coil weight requirements right from 25Kg. to 1000Kgs. Horizontal side winder take ups, Vertical drop coiler with or without pattern lay and strip take ups in our manufacturing programe.

Rolling Mill Reheating Furnace

Get Price Quote

We are engaged in offering well-designed Rolling Mill Reheating Furnace. The Rolling Mill Reheating Furnace is manufactured using technologically advanced machinery, ensuring high international standards. Strict adherence to optimum quality is maintained throughout the production of the Rolling Mill Reheating Furnace. The Rolling Mill Reheating Furnace can be availed at the market leading prices from us. Attributes Robust constructionLong service lifeHighly efficientConsistent performance

Rotary Melting Furnace

Get Price Quote

Strand Annealing Furnace

Get Price Quote

We offer Strand Annealing Furnace. For H.S. & H.C. Steel wires electro & hot deep Galvanising plants ranging from 5mm to 0.4mm sizes with latest pickling system & feum extraction system.

induction furnace spare parts

Get Price Quote

Nikum is one of the few manufacturers for Induction Furnace spares. With more than 500 furnace clients Nikum’s product and services have proven to be one of the most reliable and innovative in the market. Few of the products are mentioned below. For further details, download the product list.

Wire Galvanising Plant

Get Price Quote

S M INDUSTRIES group provides its customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups. By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for Galvanizing of High Carbon and Low Carbon Steel Wires. S M INDUSTRIES has become the pioneers in supply of turnkey projects for the wire industry; we will maintain this position trough reliable equipment and service to our customers worldwide. Technical Specification Online Fumeless Pickling System with water curtains to prevent any acid fumes form exiting the pickling system. Zinc Bath furnace consisting of Structural Steel Frame which is completely lined using several layers of ceramic refractory.

wire galvanizing plant

Get Price Quote

East Land Industries is known to be a leading Steel Wire Galvanizing Plant manufacturer. These plants are facilitated with latest pickling system and fume extraction system and are also available in various sizes ranging from 5mm to 0.4mm. Our range of machines is ideal for MS & HC Steel wires, electro and hot, and dip wire galvanizing plants. We provides our customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups.

Industrial Gas Burner

15,000 Per unit

Galvanized Wire Plant

Get Price Quote

Meenakshi Wire Products provides its customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups. By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for Galvanizing of High Carbon and Low Carbon Steel Wires. MWP has become the pioneers in supply of turnkey projects for the wire industry; we will maintain this position trough reliable equipment and service to ourcustomer's world wide. The plant consists of the following : Pay Off Stands: Revolving Turn Tables with brake tensioners for wire formers and spools, overhead Coil Opener type Payoff, Pintal Type Pay Off for Spools and Basket Type Pay Off for Coils. Open Hearth Furnace or Lead Bath Furnace with electric heating or Natural gas/LDO/FO combustion systems with top cover and recuparator for energy conservation. Online Fumeless Pickling System with water curtains to prevent any acid fumes form exiting the pickling system. The wires travel straight with lower tension and react with invigorated acid traveling against the wire, followed by triple stage water wash system. Intermediate wiping system in between chambers to prevent excessive carry over of fluids from one chamber to another. Vertical Gland / Seal Less Pumps for zero down time as no seal change over and routine maintence required. Stainless steel 316 fabricated Flux Tank with flue gas heating and temperature control system for energy efficiency and coating consistency. Option of Dipping type or straight path type with flux pumping system. Flux Dryer before the entry to the galvanizing bath hot plate assembly is provided for quick drying of flux which has heating through flue gases of the zinc bath furnace as rising energy costs has made conservation a prime criterion in today's plants. Zinc Bath furnace consisting of Structural Steel Frame. Which is completely lined using several layers of ceramic refractory. Best quality refractories ensure reliability and durability. Zinc Tank made out of low carbon low silicon steel plate with side bended at 90 degree welded with specialized electrodes and duly ultrasonic tested for any internal cracks. Options for Light/medium and heavy coating available. Finally wire is coiled on finishing Take ups where ASSOMAC offers several options depending on the industry use and coil weight requirements right from 25Kg. to 1000Kgs. Horizontal side winder take ups, Vertical dropcoiler with or without pattern lay and strip take ups in our manufacturing program.

Hot melt coating machine

Get Price Quote

fluidized bed furnaces

Get Price Quote

Fluidized bed combustion (FBC) is a combustion technology used to burn solid fuels. A bed of solid particles is said to be fluidized when the pressurized fluid (liquid or gas) is passed through the medium and causes the solid particles to behave like a fluid under certain conditions. Fluidization causes the transformation of the state of solid particles from static to dynamic.

Rotary Kiln Tyre

200,000 Per Set

1 Set (MOQ)

Gas Heavy Oil Burners

Get Price Quote

Gas Heavy Oil Burners / ENNE / EMME Series Offering progressive high/low or fully modulating operation this technically advanced series of Dual Fuel burners give firing rates from 630 to 5000 kW, with high maintainable efficiencies, using either fuel. supplied as progressive two stage. burners as standard, full modulation may be achieved, with a turn down ratio of 4:1 by the Addition of a sophisticated modulating control system. In this mode, these burners have been found particularly suitable for use on commercial and industrial installation where the load factor is subject to wide variations over a short time span. On oil side, correct automizing temperature is provided from the special modular plate type pre-heater. All units are equipped with a "Double Motor" feature which allows for the total shut down of the oil burner circuitry during operation on gas.

Discharging Ejector

Get Price Quote

Discharging Ejector is an electro-mechanical device which is used to expel the hot material from the re-heating furnace to the rolling mill. It has a mill housing type structure with a movable frame and can do both front and side travel for discharging of hot material (like ingots ,billets)from re-heating furnace .It comes complete with heavy stands, rollers, cooling system, wheels for cross travel, gear box, pushing arrangements etc. It uses a square billet of approx.6 meters (or more) length as the device to push the hot material out of the re-heating furnace. It is manufactured depending on the size and capacity of the re-heating furnace.