Z Purlin Roll Forming Machine

We are the prominent manufacturer, supplier, and exporter of purlin roll forming machine that is made by using the finest quality components. Our z purlin roll forming machine is stringently checked to ensure the high performance and long service life. This z purlin roll forming machine is widely used as the supporter of roofs and walls in large-scale and mid-scale construction, such as factories, warehouses, garages, exhibition centers, cinemas, theatres, gardens, and so on. consists of de-coiler leveling device punching system roll forming system post-cutting equipment hydraulic station electric controlling system run out table for product technical specifications suitable material : cold-rolled steel strip and heat-treated galvanized steel strip thickness of raw material : 1.5-3.0mm (235-345mpa) size of c purlin : 100-300mm adjustable (special size available) forming speed : about 10-12m/min power requirement : main motor power: 15 kw (depend on final design) hydraulic station power : 5.5kw (depend on final design) de-coiler drive : 5hp, leveler-3hp (total power- depend on final design))controlling system : plc & converter size of machine installation : about 15mx2.1mx1.4m.

...more

Steel Sheet Curving Machine

We are engaged in the manufacturing, supplying, and exporting of steel sheet curving machine that is assembled using the premium quality components. Our steel sheet curving machine is widely appreciated in the market due to its scientific design and robust construction. For manufacturing steel sheet curving machine, we strictly use the advanced technology, which make roof building precise and the quality get guarantee. The steel sheet curving machine, offered by us, is widely used in many industries for multiple purposes. Moreover, our clients can avail it at the market leading prices from us. highlights light weight good rigidity flexible well anti-seismic capability it adopt the reasonable load-carrying style, safety margin and can bear large wind load and brisance diversified design styles well adaptable scientific design

...more

Slitting Line Machine

We are considered as an authentic Manufacturer, Supplier, and Exporter of Slitting Line Machine known for high performance. Our Slitting Line Machine is not only for the Steel Service Cutting Industry, but also for the Pipe Industry. A lot of customers make the pipes before slitting the large coil to the small size of coils. Slitting Line Machine can do uncoiling, slitting and recoiling works. It mainly includes coil car, uncoiler, coil guide, slitting machine, scrap winder, tension unit, recoiler and coil car, hydraulic system, etc. The machine is mainly used in coil or hot rolled carbon steel, silicon steel and all the other kinds of metal materials with surface spreading. We are a professional manufacture of high-quality slitting lines. Our Slitting Lines are designed to slit all types of thin. Thick gauge strips to extremely close tolerances. The machine lines basically comprises of coil handling, strip processing and scrap management equipment. Our Slitting Lines come in Singe loop, double loop and Pull through. Push through & loop control configurations. Highlights

...more

Shutter Door Roll Forming Machine

We are a renowned Manufacturer, Supplier, and Exporter of Shutter Door Roll Forming Machine that is fabricated in accordance to international quality standards. Our Shutter Door Roll Forming Machine is stridently checked to render the variegated demands of the clients. We strictly use the best quality raw materials such as wrought iron, steel and other materials with latest technology for manufacturing Shutter Door Roll Forming Machine. The machine is highly capable of working efficiently for longer duration and can be availed in desired specifications. Applications : The shutter doors produced by the Shutter Door Roll Forming Machine are used as shutter doors of buildings, Shopes & Factories Types Shutter doors with punching Shutter doors without punching Consists of Decoiler Guiding device Roll forming system Cutting device Hydraulic station Control system Product supporter Technical Specifications Suitable Material : Cold Rolled Mild Steel, Aluminum, Galvanized Sheet, Pre coated SheetThickness of Raw Material : 0.4-0.8mm (235-345Mpa) Material of Cutter Blade : Cr12 mold steel with quenched treatment, HRC58-60 Power Requirement : Main motor power: 4Kw (Depend on final design) Hydraulic station power : 2.2Kw (Depend on final design) Electric Panel : Provide Electric A.C Panel for All motors with PLC Drive

...more

Roofing Sheet Making Machine

Color Coated Roofing Sheet Roll Forming Machine

We are engaged in the manufacturing, supplying, and exporting of Roofing Roll Forming Machine that consists of a De-coiler, sheet guiding equipment, roll forming system, post-cutting equipment, hydraulic station, electric controlling system and run out table for product. Our Roll Forming Machine is widely appreciated by the clients all around the world due to smooth and flexible performance and robust construction. Further, this Roof Roll Forming Machine is widely used for manufacturing steel sheets that are used for the roofs of fabricated buildings. Applications Roofs of gardens Factories Exhibition centers Villas Technical Specifications Suitable Material : Color steel sheet or galvanized steel sheet Main 3KW Thickness Of Material : 0.3mm~0.7mm Material Expand Width : 1220mm Electric Tension :

...more

Metal Slitting Machine

Metal Roofing Sheet Molding Machine

We are offering metal roofing sheet molding machine. Metal roofing sheet rolling we manufacture metal roofing sheet rolling and in the process adding rigidity & strength to the metal. These sections have wide scope of use in building and construction.

...more

Hydraulic Uncoiler Machine

The company is engaged in manufacturing, supplying, and exporting of Hydraulic Uncoiler Machine that is fabricated as per set industrial standards. Our Hydraulic Uncoiler Machine is available in both motorized and non-motorized form that is stringently checked on quality parameters. These machines are available in various capacities and specifications to meet variegated demands of clients. The Hydraulic Uncoiler Machine can make stretch coil-deliver coil automatically, the speed of which is same with the forming machine. It is a matching machine for colored steel equipment. In order to save human recourse and lower labor cost, it is better to work with colored steel mould machine and stacker, with which it formed a completely producing line. Technological Process Uncoiling Feeding Leveling Punching Rool Forming Cutting Products Collecting Technical Specifications Re-Coiler machines are up to 10 ton capacity Width up to 1500 mm Jaws expansions by manual or hydraulically operated Main shafts are of alloy steels All bearings are reputed make Coil car carrier-optional All Hydraulic equipments and other brought out items are of internationally reputed make

...more

Hydraulic Strike Bending Machine

We are one of the leading Manufacturers, Suppliers, and Exporters of Hydraulic Strike Bending Machine that is fabricated as per the international quality norms. Our Hydraulic Strike Bending Machine known for its high performance and easy operation. The Hydraulic Strike Bending Machine, offered by us, is equipped with a motor-drive device that makes the bending process more efficient and effective. Technical Specifications Overall dimension(mm) : 3000*1520*1600Weight(kg) : 800Capacity(kw) : 4Thickness(mm) : 0.4-0.8 Highlights This metal sheet roll forming machine is widely used to bend the steel roof sheets Equipped with a motor-drive device Easily and conveniently to operate Affordable prices

...more

Guardrail Roll Forming Machine

We are the reputed Manufacturer, Supplier, and Exporter of quality Guardrail Roll Forming Machine that is used as guardrails on expressways, roads, and many other premises. The Guardrail Roll Forming Machine, offered by us, is widely demanded in the market due to its high strength and long service life. Our machine consists of a decoiler, leveling system, punching equipment, roll forming system, cutting equipment, hydraulic station, control system and product supporter, which make it as the best choice in the market. We provide Guardrail Roll Forming Machine at the market leading prices. Technical Specifications Suitable Raw Material : Galvanized steel sheet Material Thickness : 2-3.0mmTransmission : Gear box Total Motor Power : About 35Kw (Depend on final design) Control system : PLC & converter

...more

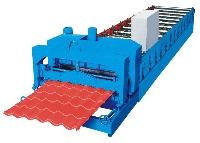

Glazed Tile Roll Forming Machine

The Glazed Tile Roll Forming Machine, offered by us, is assembled in accordance to international quality standards. This machine is widely used in Construction Industry for producing colored steel tiles, which enhance the beauty of your premises and make it look classy, noble & elegant. Further, the machine is used for the roofs of Gardens, Factories, Hotels, Exhibition centers, Villas etc. Our clients can avail Glazed Tile Roll Forming Machine at the most competitive prices. Consists of Decoiler Sheet guiding equipment Covering film device Roll forming system Pressing device Post-cutting equipment Hydraulic station Electric controlling system Run out table for product Process Uncoiling Feeding Leveling Punching Roll forming Cutting Products collecting Technical Specifications Suitable Material : Color steel sheetMaterial Thickness : 0.4-0.6mmStep Distance : Adjustable according to requirement (>=250mm) Power Requirement : Main motor power: 5.5 Kw (Depend on final design) Hydraulic Station Power : 5.5Kw (Depend on final design) Controlling system : PLC & converter

...more

Double Layer Roll Forming Machine

We are offering Double Layer Roll Forming Machine that is assembled in accordance with the industry norms. The Double Layer Roll Forming Machine, offered by us, consists of finest quality components that include Hydraulic station, Cutting device, Support table, and many others. Our easily operated Double Layer Roll Forming Machine is available in various thickness, motor powers, and sizes. Besides, we also provide customization on Double Layer Roll Forming Machine as per the clients� needs & offer it at the most affordable prices. Consists of De-coiler Coil sheet guiding device Main roll forming system Cutting device Hydraulic station PLC control system Support table Technical Specifications Suitable Material : Color steel sheet or galvanized steel sheet Machine Sizes : 11000�1400�1100mm Main Motor Power : 5KW with Cycloidal reducer Hydraulic Station Power : 3KW Thickness of material : 0.3mm~0.7mm Material expand width : 900mm-1220mm Electric tension : 380V 3phase 50HZ or as the customer's requirements Electric Panel : Provide Electric A.C Panel for All motors with PLC Drive

...more

Corrugated Sheet Roll Forming Machine

cold roll forming lines

Cable Tray Roll Forming Machine

The Cable Tray Roll Forming Machine manufactured, exported and supplied by us, is used for producing cable trays that are used in various factories and buildings. We provide Cable Tray Roll Forming Machine that comprised of efficient Punching Machine, Hydraulic Station, Electric Controlling System and many other options, which make it an ideal choice for many. The Cable Tray Roll Forming Machine can produce both quality and quantity cable trays in less time. Consists of Active hydraulic decoiler Sheet leveling equipment Punching machine Roll forming system Cutting equipment Hydraulic station Electric controlling system Supporter for product.

...more

C Purlin Roll Forming Machine

The c purlin roll forming machine manufactured, supplied and exported by us is strictly assembled in accordance to the international quality standards. Our c purlin roll forming machine is used as the supporter of roofs and walls in large-scale and mid-scale construction, such as factories, warehouses, garages, exhibition centers, cinemas, theatres, gardens, and so on. Moreover, we provide customized c purlin roll forming machine at the market leading prices. consists of de-coiler leveling device punching system post-cutting equipment roll forming system hydraulic station electric controlling system run out table for product technical specifications suitable material : cold-rolled steel strip and heat-treated galvanized steel strip thickness of raw material : 1.5-3.0mm (235-345mpa) size of c purlin : 100-300mm adjustable (special size available) forming speed : about 10-12m/min power requirement : main motor power: 15 kw (depend on final design) hydraulic station power : 5.5kw (depend on final design) de-coiler drive: 5hp, leveler-3hp (total power- depend on final design))controlling system : plc & converter size of machine installation : about 15mx2.1mx1.4m

...more

Industrial Machines

Roll Forming Machines

Roofing Sheet Roll Forming Machine

Cut to Length Line Machine

Forming Machines

Rolling Machine

steel structure machines

Be first to Rate

Rate This