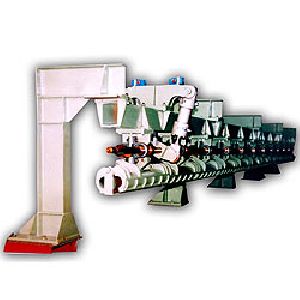

Twin Channel Machine

Our company is engaged in offering high grade Twin Channel Machine that is widely installed along the side of the entry of the cooling bed. The twin channels consist of alternatively opening flaps through a hydraulic cylinder and CAM system. In this, the bar enters the closed flap that opens when the full bar has been obtained. It has a free fall on the straightening pockets of the rake type cooling bed, which moves on the fixed & moving rakes to the mill run out table. In this, the water is cooled to prevent warping during rolling that is suspended from a longitudinal structure. The closed twin channels ensure that the bars do not come out and maintain safely of the people involved in the process. Here, the opening and closing of the channels is done through cam-shaft and follower rollers. The Twin Channel is successfully operating at the finishing speed as high as 21 m/s producing 20MT/hr of re bars. THE TWIN-CHANNEL BAR RECEIVING MECHANISM COMPRISE OF THE FOLLOWING Twin water-cooled C-type channels with water cooling arrangement Supporting arrangement for the twin-channel and drive system Cam device for opening closing of the pipes Hydraulic drive for operation of the cams

...more

TRAVELING TYPE HOT SAW

We offer Traveling Type Hot Saw, which is chiefly required in steel & metal industry and construction industry. In this, the hot saw is positioned before the cooling bed, where the rolled section is cut to the given lengths. The traveling hot saw is placed at a good distance from the fixed saw. Further, this distance can be altered equal to the travel of the hot saw along axis of rolling. Traveling hot saw after cutting the grip releases and the cut section is delivered on the cooling bed. The length of the rolled section and the number of cuts required along the length of the section determines the number of traveling hot saw required in a given situation. FEATURES Rolled section is gripped on the run out roller table Cuts heavier section with better straightness Heat resistant Removes trim front & rear end with ease Superior durability Tough built Easily cuts beam, channel and angle Increases the productivity of extrusion system Cuts every billet to the uniform size Precise & sharp tooth Corrosion free Accurate dimensions APPLICATIONS Engineering industry Metal industry

...more

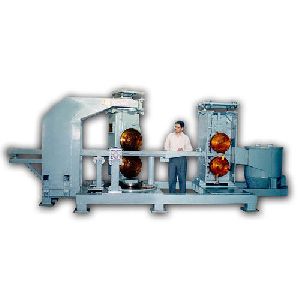

TRANSMISSION TOWER MACHINERY

We are engaged in developing supreme quality Transmission Tower Machinery, which is widely installed in steel and automobile industry. It carries out notching and has alphabet pressing at the punching station. We offer this machinery with several optional equipments. Our transmission tower machinery comes with coordinating tables for punching of structural steel plates from a sample template without any pre-marking. It has linear system for the punching of the profiles with manual program. This is achieved by several mechanical stops. Our cropping station is multipurpose, which accommodates angles I- beam, channels, tee section for full range. Our transmission tower machinery capacity ranges from 40 Ton to 140 ton.

...more

Tmt Quenching Boxes

Our company is engaged in developing prime range of TMT Quenching Boxes that provides multiple entry of fresh water at regular time duration into the nozzles. This is equi-spaced along the cooling length at specified pressure and volume for the controlled thickness, which enhances the efficiency of the processing. The offered TMT system in our quenching box is of multiple injector type. FEATURES Consistent ring formation Uniformity of the tensile strength along the length of the bar Motorized valves Corrosion free Less time consuming Supreme design Robust construction Highly durable Closed frame to accommodate the forces in the sizing press Can operated under harsh conditions Highly durable APPLICATIONS Engineering industry Metal industry Rolling mill industry SPECIFICATIONS Several grades FE415, FE500 & FE550 are produced by bringing the specified no of nozzles in cooling cycle and shutting others.

...more

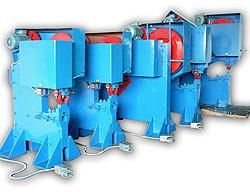

TMT MILL STANDS

The TMT Mill Stands we offer are manufactured on the basis of technically proven designs. The chock mounting and hanging system swivel as per the roll deflection reducing bearing pressure. Individual or combined lifting of both the roll necks. The changeover is facilitated by simple to engage clutch. The screw down is displayed on the dial . FEATURES Manufactured with best quality material Highly efficient Technically proven designs Reasonable price Manufactured with strict quality checks throughout the manufacturing process

...more

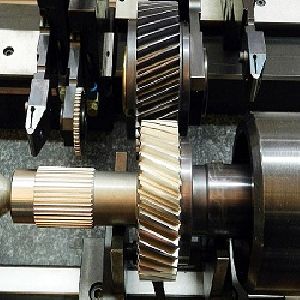

Spur Gear

Spur gears are the most common type of gears, with straight teeth and parallel to the axis of the wheel. Its simplicity in design, economy of manufacture and maintenance, and absence of end thrust are some of the advantages. Also known as slow speed gears, these impose only radial loads on the bearings. With the only shortcoming of noise, it can be utilized at almost any speed. FEATURES Highly durable & economical Efficient quality Up to 150 mm OD and 3.5 modules in steel APPLICATION Gearboxes Mining Equipment Gear Pump Unit Tandem arrangement with internal or external teeth TECHNICAL SPECIFICATION: Spur helps in transmitting rotational torque by applying force on the teeth of other gear. Being unequal in size, when combined it produces transmission where rotational speed and torque of the second gear needs to vary from the first one. To operate in rotational directions, these gears are extended in two possible arrangements for oppositely oriented helical gears/gear faces, one stable and the other unstable.

...more

SLIT ROLLING MILL

Achieving high production of high premium smaller sizes of TMT bars, utilizing fully the Reheating capacity MULTI STRAND SLIT ROLLING The dogbone, slit, finishing stands rolled through ‘Size Stabiliser Housing less Stands’, through multi strand ‘Controlled Cooling Bar Tempering system’, cut by ‘Wide Blade Flying Shear’ conveyed & braking through ‘ Lifting Apron Type entry roller table & ‘ Walking Beam Cooling Bed’ with inbuilt ‘Layer transfer system’ ADVANTAGE 15% Power saving for slit sizes, since the cross section area rolled is in multiple of strands. Fuel saving, as the furnace discharge temperature can be reduced by 40degC, as speed of rolling in roughing & intermediate stands is higher, the material gets heated during rolling. Four nos. less nos. of total stands for four slit, Less roll consumption per ton. EXAMPLE TO KNOW HOW THE ROLLING MILL CAPACITY IS DECIDED Suppose these are the technical specifications for a mill (250,000 TPA) We have explained How to Calculate the production for such a mill.

...more

Rolling Mill Stands

Our mill stands are manufactured on the basis of technically best designs. Our mill stands are manufactured on world class machinery. Our team is headed by our director who is well known for his technical knowledge and experience which is reflected in the work we do Our mill stands are well known because of their performance and long life. Our company is very keen on our the quality , our mill stands go through quality checks throughout the manufacturing process. FEATURES Increases driveline Reduces operating costs Achieve more efficiency Lifter moves up to align the core with the chucks Corrosion free Weather proof Cost effective operation Boosts bearing performance higher reliability APPLICATIONS Rolling mill industry Steel industry

...more

Rolling Mill Machinery

We are engaged in offering high quality Rolling Mill Machinery Manufacturers in India , which are extensively demanded in rolling mill plants . These equipments are manufactured by using advanced technology. OUR RANGE OF HOT ROLLING MILL EQUIPMENT INCLUDES: Mill stands flying shear Quenching box/tmt box automatic cooling bed crank shear disc and drum shear rolling mill gearboxes Roughing stands intermediate stands finishing stands rolling mill gearboxes cold shear disc and drum shear FEATURES technically best design long life sturdy manufactured on world class machineries shorter pay back period highly efficient APPLICATIONS Rolling mill industry Steel industry

...more

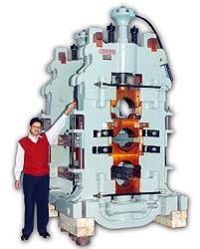

Housingless Mill Stands

We are offering premium quality Housingless Mill Stands that are widely known for their durability and optimum performance. The offered products are manufactured using the best quality raw material and the most advanced techniques by our skilled professionals in complete compliance with the industry quality standards. The offered stands can be vertically or horizontally mounted for flexible use in H/V mills. Clients can avail the entire range from us at the most competitive prices. FEATURES Sturdiness Comes with screw down display with least count of 0.025 mm Optimum quality Rust resistant

...more

hot rolling mills

We also provide complete turnkey rolling mill solutions from designing, manufacturing, mill commisioning to our clients since 28 years. We have been leading the rolling mill industry and moving forward with our aim of continous improvement and setting benchmark in the steel industry. We plan and design the mill by keeping the customers requirement as the focus and also insuring future expansion possibilities. nav bharat is leading the rolling mill industry and winning trust worldwide. Our mills can be fullyautomatic or semi automatic as desired by customer. We have divided tmt bar rolling mills according to their capacity 60,000 TPA TO 80,000 TPA (Furnace capacity 16/20 TPH) 100000 TPA TO 1,25,000 TPA (Furnace capacity 25 TPH) Upto 250000 tpa (Furnace capacity 30-40 TPH) 300000 TPA to 500000 TPA (Furnace capacity 5O -100 TPH)

...more

helical gear box

Our company develops supreme quality Helical Gear Box that is widely used in applications involving high shock loads. These gearboxes maintain superior efficiency and can bear supreme high load applications. It is constructed from cast iron for small and medium size units. In this, the stress zones are amply ribbed against distortions under dynamic load. The internals are heat treated up to 300 BHN for pinions and upto 260 BHN for gears prior to teeth cutting. The shaft extension is provided with long holes at ends and grooves under bearing seats for removal of bearing & coupling with hydraulic injections. FEATURES External heat exchangers are provided at necessary places Made of casted iron and casted steel Stress zones are adequately ribbed against distortion under dynamic load Provided with long holes in shaft extensions at ends Coupling with hydraulic injection system Dimensional accuracy Optimum performance Shaft ends with u6 tolerance Offered with scrapers and forced lubrication, available as per the suitability Positive flow of oil into the bearing on either direction of rotation APPLICATION Automotive industry Steel industry Rolling mill industry Precisely design

...more

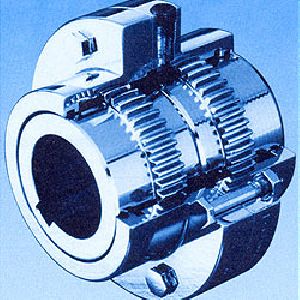

Gear Couplings

Our company provides supreme quality Gear Couplings which has application in different industries like steel industry, cement plant,sugar mill plant ,metal industry.It primarily provides connection between two shafts, which are together, attending the purpose of transmitting power. These gear coupling are rigid as well as flexible, which comprises of two hubs with an external gear and two outer sleeves with an internal gear. Our gear coupling is universal and is compatible for angular, offset and combined as well as large axial moments. SPECIFICATIONS The hubs are completely machined from EN-8/EN-9 material forged, annealed and heat treated from 235-265 BHN The Casings are made out of EN-8/EN-9 forgings material up to 107 and Cast IS-1030 Gr 23/45, heat treated from 235-265 BHN above 107 The teeth cutting are done maintaining D.O.P /SPAN for required sliding tolerances. All parts are completely inter-changeable Range of Gear Couplings up to 119 Nos The Gear Couplings up to 110 are always in our ready stock

...more

Gear Box Manufacturers

We "Nav bharat Engineering Works" is engaged in manufacturing, supplying, trading and exporting high quality range of Industrial Gear Boxes & Gear Coupling , etc. Our products are in high demand across industries such as Stone Crushing Plants, Quarry Plants, Conveyor Equipments, Asphalt Plant, and Road Construction Plants. We deals in India ,Sri Lanka,Nepal,Dubai etc market in which the clients from heavy industries are our intended audience. Our reputation is to deliver products of high-grade finish, excellent quality and high performance to our clients. To build the entire series of high performance products, we source the raw material for the most trusted suppliers only. We ensure that only high grade raw material and genuine components are used in the manufacturing these gear boxes. Our entire manufacturing process is governed by a set of stringent quality measures that are designed to assist us in developing a superior and long lasting product. Our exporting countries are Sri Lanka, Bangladesh, Srilanka, Indonesia, Uganda etc. FEATURES Coupling with hydraulic injection system Dimensional accuracy Optimum performance Shaft ends with u6 tolerance Offered with scrapers and forced lubrication, available as per the suitability Positive flow of oil into the bearing on either direction of rotation Precisely design External heat exchangers are provided at necessary places Made of casted iron and casted steel Stress zones are adequately ribbed against distortion under dynamic load Provided with long holes in shaft extensions at ends APPLICATION Rolling mill industry Automotive industry Steel industry

...more

Flying Shear Machine

LOCATION The Flying is Shear placed between the Quenching Box and the Cooling Bed. APPLICATIONS To cut the T.M.T. Bar at a temperature of 500oC and above to the required lengths. FEATURES The 1000 mm CRS (adding to the manufactures cost because with 1000 mm centres the depth of the shear also has to be increased leading to increased dia gears, shaft lengths, casing weight) instead of 800 or 850 CRS so as to reduce the base rpm of the drives Motor. Since it is a start stop shear the motor shall have to accelerate to lower (base) rpm hereby reducing power consumption on recurring basis and generate payback. The casing is prestressed to prevent seperating of casing parting surfaces on load during the milli seconds when the cut is executed. The cutter ends are involute profiled at ends. The cutters engage before the bar touches the cutting edge, eliminating possibility of erroneous blade over lap. We provide an optional arrangement of Flywheel with mechanical clutch. The flywheel is engages for cutting above 20 mm bar size. The flywheel inertia augments the lower power available from constant torque motor running at low rpm to match thicker bar rolling speed. The casing front end and pinch roll cantilever shaft is water cooled to avoid distortion with heating. The gears are case carburised hardened & ground designed for minimum back lash. Again the gears and knife holders are designed for minimum intertia.

...more

double helical gear boxes

Double helical gear has both left- right helical teeth, is used to balance the thrust force and provide additional gear shear area. Also known as Herringbone gears, which resemble two helical gears that have been placed in an adjacent manner. Being double helicals, the thrusts are counter-balanced with no thrust loading on the bearings. FEATURES Teeth grinded on hofler gear grinder, mot is checked post operation, surface finish, geometrical accuracy, contact with the mating part are checked, 70%, backlash is checked whether it is within the limits. Apex is checked in case of shrink, distance between two gears is checked, and material is 18crnimo6. Gear quality –Din1 and Din 2 Teeth cutting on hobbling operation maintaining the teeth grounding allowance. Gear machined using tools and inserts from world’s best tool manufacturer like seco and sandvik Sharpening of gear cutters done on German machine klingenberg sharpener Grinding is done on cnc gear grinder using grinding wheels of Winterthur APPLICATION Heavy machinery External gear pumps Required on higher pressures & larger percentage of filled materials TECHNICAL SPECIFICATION: These gears are placed in V shape as two mirrored helical gears joined together. The mirrored arrangement revokes net axial thrust as each half of gear thrusts in opposite direction. To operate in rotational directions, these gears are extended in two possible arrangements for oppositely oriented helical gears/gear faces, one stable and the other unstable.

...more

DISC and DRUM SHEAR

LOCATION The Disc & Drum Shear is placed between the Roughing and intermediate Mill. APPLICATION To Cut the front and back end of the squares upto 32 mm at 900o C In case of misroll at the Intermediate or Finishing Mill the deviator pipe is shifted directing the bar to the Drum Shear which cuts It into scrap pieces ADVANTAGES In the mills the Snap Shears are mounted on repeaters to cut the bar in case of misroll, but the bar which is coming from the Roughing Mill is continuously fed into the mill is getting entangled on the roll. This feeding of the bar is stopped by cutting at the Drum Shear, thereby drastically reducing the down time of the mill in case of misroll. FEATURES Both Disc & Drum Shear are with case carburised, hardened & ground gears, (almost eliminating teeth wear) with near zero backlash. The cut pieces at the Drum Shear are collected in a tray placed under the silo, keeping the surrounding clear and enabling easy removal

...more

Crank Shear

LOCATION The Crank Shear is placed between the Roughing train & the Intermediate train. APPLICATIONS To cut front/back end & Cobble cutting of the square at a temperature of 900 deg C and above. FEATURES The casing is prestressed to prevent seperating of casing parting surfaces on load during the milli seconds when the cut is executed. The cutter ends protrude, so as to have increased blade grinding margin. We provide two nos. Flywheels with mechanical clutch. The additional flywheel has to be engaged for cutting heavier section. The flywheel inertia augments the power available for cutting from constant torque motor. The casing front face is water cooled to avoid distortion with heating from moving rolled stock. The gears are case carburised hardened & ground designed for minimum back lash. Again the gears and knife holders are designed for required intertia. ADVANTAGES The square shaped cobble cutting is saleable material to be rolled in scrap rolling mills.

...more

CONTINUOUS ROTATING SHEAR

ADVANTAGE The Start Stop Flying Shear can cut upto 18m/s with the standard DC motors. The solution lies in installing High Speed Continuous Rotating Shear with regenerative Tail Breaking Pinch rolls. The speeds of 22m/s with pneumatic deviator & 30 m/s with servo motor deviator have been achieved. The first cut of this shear is not accurate, but the subsequent cuts are very accurate. The material loss of first cut is compensated by the subsequent cuts. The motor power is only 50 KW, compared to 90, 130, 175 KW of Start Stop Flying Shear. RANGE 8mm to 16mm TMT bar. Single Shear is sufficient for ingot rolling mills. APPLICATION To cut set lenth of TMT bar being rolled above 20m/s at a temperature of 550 deg C FEATURES The casing is vertically split to take the separating force during the the milli seconds when the cut is executed on the casing profiles instead of parting bolts. The blade holder is fitted with double cone torque couplings as a safeguard against the accidental overload. The Flywheels are provided to reduce the motor power. The flywheel intertia augments the cyclic cutting load. The gears are case carburised hardened & ground designed for minimum back lash.

...more

CHAIN TRANSFER SYSTEMS

Our company designs supreme quality Chain Transfer Systems, which are installed at the side of run out roller table after the cold shear. In this, the first chain set cuts across the run out roller table after the cold shear. It has its resting on the common tie bar, which is fixed with the pneumatic cylinders. The cut bar lot in the system received on the run-out roller table, where the chains set lifts. Here, the chain moves across the rolling line & shifts the cut bar lot to the set distance of the chain transfers. Further, the middle chain runs at superior speed to spread bar for removing the random length and the third chain for manual bundling. Therefore, in last the bundle is thrown in the cradle or on to some other roller table where transferring it to U- bending station is done.

...more

Automatic Cooling Bed

Our company is engaged in offering supreme quality Automatic Cooling Bed that is primarily used for purpose of uniform air-cooling of TMT bars and transporting the same in a phased manner. This transporting is done from the entry of the cooling bed to discharge side. In this, the front end of the bars is also leveled at the discharge side and a fixed number of bars are sent for final length cutting by cold shear and bundling. The mechanism of our cooling bed assures that the bars are uniformly positioned over the toothed racks. Our cooling bed is designed considering the finishing mill stand of the mill and cooling time required for the various sizes of the bar.

...more

cold rolling mills

Our company is profoundly involved in developing supreme quality Cold Rolling Mills that are extensively installed in steel & metal industry, construction industry and engineering industry. It helps in achieving the desired thickness and shape of various metals. Our cold rolling mills operates on high speed and productivity. It is built on latest technology that allows high quality products. The mill operates on low cost as it is highly efficient and durable. Our 2 hi, 4 hi and 6 hi stands are rugged in construction and accurate in designs. The mill housing is cast steel duly annealed to make surer total stability of dimensions. In this, the roll can be adjusted mechanically, hydraulically or electro-mechanically both in vertical and axial direction. Our mill drive in cold rolling is able to handle harsh environment and gear box ensures heavier anti-friction bearing in limited centers.

...more

FIXED TYPE HOT SAW

We offer Fixed Type Hot Saw, which is extensively installed in various steel & metal industries. These are placed before the cool bed where it cuts the front end of the sections. Here, the rolled section is gripped on the run out roller table and fixed saw plunges at the required angle to the rolling axis. It cuts the section at the front end as well as at the required lengths. FEATURES Corrosion free Accurate dimensions Heat resistant Removes trim front end High durability Increases the productivity of extrusion system Cuts every billet to the uniform size Sharp & accurate tooth robust built Easily cuts beam, channel & angle APPLICATIONS Steel & metal industry Engineering industry

...moreBe first to Rate

Rate ThisOpening Hours