Spandex Yarns

Spandex Yarns Spandex is more stretchable than rubber as its tensile strength is several times that of rubber. It is lighter than rubber. It can be produced in a wider range of denier, including the very fine and coarse deniers which is difficult to produce from rubber. Spandex is combined with many different materials, ranging from synthetic fibers such as nylon and polyester to natural fibers like wool and cotton.

...more

nylon 66 yarn

Nylon 66 (PA66) yarn manufacturing technical are more sophisticated. The products of PA66 feels more comfortable, soft to the skin. Therefore, these yarns are more suitable for high-classed market, like seamless knitting. Our products are widely used in Knitting, Sewing, Seamless, Weaving, Hand Knitting, Socks, Underwear, Cloth, Wrap yarn, Gloves and Hosiery.

...more

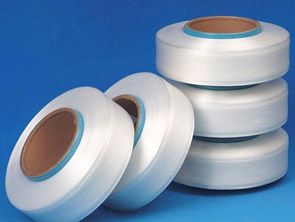

Fusible Bonding Yarn

These yarns are low-melt multi filament yarn used for technical applications in the clothing industry worldwide. These yarns are made from either low-melt co-polyamide (nylon) or co-polyester (polyester). Yarns are produced to melt at a range of temperatures and in various yarn counts (D/TEX). Melt Temperatures: 60°C and 160°C D/TEX: 23 - 840 140°F and 320°F Fusible Bonding Yarn are used in the textile industry to: Improve quality of finished garment Solve production problems Innovate new production techniques

...more

air covered yarns

These yarns, which are very much in demand, are now produced by the RC Yarns on fully automatic, state-of-the-art SSM air-covering machines. The manufacture of air-covered yarns is our most efficient production process rendering it therefore particularly cost-effective. In this process, the elastane component is intermingled with a filament yarn using compressed air and wound straight onto the yarn spool. Air-covered yarns have a powdery look and an exceptional softness. They are mainly used for socks, Inner Wear, Sports Wear, Active Wear, Swim Wear, and seamless. Hard twist yarns For the warp in weaving, air-covered yarns undergo an additional working step on a two-for-one twisting machine which means that the sizing process can be omitted. Hard twisting results in improved strength and evenness, giving the final product a smoother surface.

...moreBe first to Rate

Rate ThisOpening Hours