Vibrating Screens

500 Per Piece

4 Piece(s) (MOQ)

spring steel wiremsh with edge preparation is widely used in industries for washing, sizing, scalping, and many other applications. The hook strips on the edges make these screens highly stable under greater and uniform tension. The edge preparation in the screen protects it against distortion and excessive vibration that further causes metal fatigue and breakage. as our company is growing day by day, the list of clients is also increasing and today; we have marked a niche in not only domestic but also in international market. With our internationally certified products, we have revolutionized the global market place.our clients are spread across the corners of world, recommending our products for their durability, designing accuracy, dimensional tolerance and adaptability to work under adverse conditions.

Aluminum Welding Cables

Get Price Quote

500 Meter (MOQ)

Best Deals from Welding Machinery

Hand Held Laser Welding Machine

Get Price Quote

1 Piece (MOQ)

HF Solid State Welder

Get Price Quote

100 Piece (MOQ)

We are chiefly engaged in manufacturing, supplying and exporting the top-tier HF Solid State Welder in India and overseas. In sync with current industry standards, our Solid State Solid State High Frequency Welder are acclaimed for immaculate quality and operational stability. Offered in variable specifications, these HF Solid State Welder are obtainable from us at nominal prices. Owing to our appropriate choice of packaging and shipment, we execute safe & steady delivery. Features : The solid state H.F. welder adopts Germany IXYS company IXFN38N100Q2 38A/1000V high-power MOSFET and DSEI 2×61-12B 60A/1200V rapid recovery diode to compose series type invertible circuit. The solid state H.F. welder adopts modularization design with more compact structure which makes maintenance and high-power realization much easier. It has particular technology of bridge-divided over-current protection that guarantees equipment safety. It combines international advanced control method of same products, adopts advanced technologies like fixed angle phase-locking control, upper frequency limit/lower frequency limit lock-lost protection and etc. With these technologies, the equipments run more stably, more efficiently, more accurate and effective protections to the inductor short-circuit and open-circuit malfunction during pipe welding production. It has most advanced Electronic automatic load matching technology (PS+PWM control tech), it make machine working at best condition. Buyer doesn’t need change any parameter under induction/contact welding types. Line-in end of solid state H.F. welder does not need step-up /step-down rectifier transformer, compared with vacuum tube welder and parallel type welder; it has significant energy-saving effects (Under same welding condition, energy-saving ≥30% compared with vacuum tube welder). Working principle of solid state H.F. welder Solid state H.F. welder main circuit structure is as follows fig.1; it is a typical AC-DC-AC variable frequency structure. Rectifier adopts 3-phase bridge style thyristor phase-control rectifier circuit, DC side adopts inductor, capacitor to compose LC filter which meet the working requirements of voltage type inverter. The voltage type inverter adopts modularization parallel structure to extend power supply power, each inverter module is single phase MOSFET bridge style circuit connected with series resonance tank circuit by H.F. matching transformer. On one hand, the matching transformer realizes power combination and impedance matching; on the other hand it realizes electric isolation of load and power supply. To put effective and swift protection on over-current malfunction of voltage type inverter, our company introduces special and stable over-current protection circuit which guarantees safe and stable running of inverter. Electronic automatic load matching technology of solid state H.F. welder Load matching is to make equivalent impedance of load equal to impedance required (RN=UN/IN) to output rate power. Good matching is guarantee for output and stable working. The welder’s load’s equivalent impedance will change with changing of parts and cause load matching problem. If load is not matched, welder will not output rate power. When welder and load both are matches, i.e. welder also in best condition and best loading capacity. Now the ways to adjust load matching: adjust parameter after machine stops (induction size, diameter and resonant capacitor) or change parameter by step motor, not well. Our welder has Electronic automatic load matching technology, this technology can only use on Series welding machine which decided by its features, below figure is automatic load matching and output curve of voltage, current and power output. Advancements of Electronic automatic load matching technology Buyer doesn’t need change any main parameter to get load matching based on different tube materials. Welder can guarantee rated DC current, adjustable DC current continuous liner. AC Side power factor is high (>0.9 when load is 50%), when output equals DC power, input side current and harmonic current is minimum. Welder can get better efficency, 5% higher than same level welders. Buyer doesn’t need to change main parameter to get switching between induction/contact types. Auto matching range according to different working frequency, 100kW~300kW welder: range 30%; 400kW~800kW welder: range 40%; 800kW~1200kW welder: range 50%.

Hot Wedge Welder

Get Price Quote

1 Piece(s) (MOQ)

We are engaged in offering excellent quality Hot Wedge Welder (BAK-SeOn) to our valuable clients. This machine is fully designed with latest technology and it is widely used for welding of tarpaulins, thermoplastics & banners. * Fast * Efficient * Quiet * High-speed * Low-priced * Maintenance free Features: - High seam production because higher welding speed - Weld thin material perfect - Welding parameters can be saved - Optimal heat transmission with new ceramic wedge Technical Data: Voltage : 230 V Frequency : 5060 Hz Power Consumption : 1050, 1420, 1790 W depend on edge width Temperature : 20-425°C Seam Width : 30, 40 mm order 50 Speed : 0.5 – 42 mmin Size (L x W x H) : 540 x 330 x 280 mm Weight : 23 kg Marking : CE Advantages of the product: * New wedge design with higher welding speed. * Noise and smoke free. * Latest Technology. Clients can avail this Hot Wedge Welder (BAK-SeOn) at industry leading prices from us.

Welding SPM

Get Price Quote

If seeking for the well-designed and highly-efficient Welding SPM, we are the name to be reckoned with. We share glorious credentials in the list of top Manufacturers and Suppliers of the Welding SPMs in India. Our accomplished team fabricates these Machines as per the dimensional specifications given by the clients. Compliant with the industry guidelines, these Machines are attainable from us at the nominal prices.

Butt Welding Machine

Get Price Quote

With sincerity and hard work, we have carved a niche for ourselves in this domain by offering best quality Butt Welding Machines. Further, to ensure the higher level of patron satisfaction, we manufacture these welding machines as per the specified details. We manufacture these welding machines by using modern machinery, latest technology and best grade raw material, sourced from trusted vendors. Specifications: Pneumatically operated flash Butt welding machine transformers 50 KVA Equipped with microprocessor controller model nash - 850 n and AC motor drive

TIG 300 WELDING MACHINE 3 PHASE

21,999 - 24,999 Per 1 SET

1 Set (MOQ)

Argon Welding Machine

25,800 Per Piece

1 Piece (MOQ)

Welding Penetration System

Get Price Quote

Banbros offers you the most advance system of weld penetration inspection with specially design high resolution microscope and USB digital microscopic camera to view and instantly capture a photograph and measure exact weld penetration depth in all type of weld sample with the help of user friendly software. The system can be used to measure all dimensional measurement (2D) like length distance radius diameter etc.

UPVC Manual Welding Machine

60,000 Per Piece

Single Head Welding Machine

150,000 Per Piece

Features : Less power consumption Easy to operate Precisely engineered

Welding SPM

Get Price Quote

We offer an efficient Welding SPM to our clients. Welding SPM is durable is used for various welding purposes. Welding SPM is available in several profiles like round, linear etc. Welding SPM is sturdy and tamper-proof. We have made Welding SPM available in different specifications, to cater diverse demands of the clients.

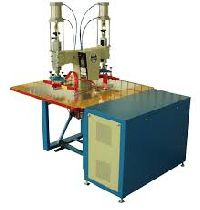

high frequency welder

Get Price Quote

We are known as a prominent High Frequency Welders Manufacturer, Exporter, and Supplier in India. The High Frequency Welders are available with us in a wide range that is designed as per the set industrial standards. Our assortment of High Frequency Welders comprises of Vacuum Tube Induction Welders and Solid State Welders. These High Frequency Welders are efficient in performance and long lasting in nature. The High Frequency Welders can be availed from us at the most competitive prices.

Fully Automatic Ear Loop Welding Machine

Get Price Quote

1 Piece(s) (MOQ)

Welded Wire Mesh Machine

Get Price Quote

We present Welded Wire Mesh Plants that are used for manufacturing wire mesh for fencing purposes. The plants are manufactured in accordance with set industrial standards using graded materials and components. The wire mesh plants offered by us are high on withstanding capacity and require less maintenance. Salient Features Range of Cross Wires (mm): 1.3 - 2.0 to 2.5 - 6.0 Cross wire spacings (mm): 10-100 to 25-200 Line wire spacings (mm): 15-100 to 50-200

Welding Machine

Get Price Quote

Anti Spatter Spray

Get Price Quote

Vibrating Screens

Get Price Quote

gb kore arc 250 st welding machine

7,200 - 8,500 Per Pc

1 pcs (MOQ)

Aluminum Alloy Welding Wire

Get Price Quote

Sheathed Instrumentation Cable

10 Per Meter

100 Meter (MOQ)

Wire Butt Welders

Get Price Quote

Owing to our rich domain expertise, we are manufacturing and supplying a wide gamut of Wire Butt Welders that is extensively used for butt joining of wire. These welders are fabricated with utmost precision as per the latest technological advancements under the guidance of our skilled professionals. Our offered welder is highly admired by clients due to its low maintenance, enhanced performance, sturdy construction and longer service life. These are available in various sizes as per the varied needs of clients. Apart from this, these are strictly tested on various quality parameters to assure their flawlessness.

WELDING CABLES

Get Price Quote

We manufacture and export high quality welding cables, which are extensively used in diverse industries across the globe. They are available in a plethora of colors and are sure to last for a long time. Abrasion & ozone proof, our welding cables can be availed at industry leading prices. SALIENT FEATURES OF HOFR WELDING CABLE: Heat oil fire retardent Electrolytic copper conductor conforming to IS :8130 Highly abrasion resistant. Long working life Less heat build up Ozone resistant

MIG Welding Torch

2,500 Per

Safety Welding Nozzles

Get Price Quote

water based anti spatter spray

Get Price Quote

MIG welding machine

90,000 Per Piece

Arc Welding Machine

11,500 Per Piece

1 Piece (MOQ)

Vacuum Tube Induction Welders

Get Price Quote