YSU-624 Dry Heat Sterilizer

1 Piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with automatic control system by Pre-programmed PLC. 2. PRE-PROGAMMED CYCLES: The sterilizer has equipped pre-programmed cycles. 3. USER CUSTOMIZABLE CYCLE: The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings. 4. PASSWORD PROTECTION: a) The sterilizer settings are password protected. b) The date and time settings are password protected, and User is able to update date and time settings on the screen for better record keeping. 5. PRINTER: a) The user is record the progress of the sterilization cycle in real time therefore online real time printing facility will be provided. b) The user can print the following details: Date and time of the cycle. Status of the cycle. Temperature at drain and chamber pressure at every event change and during sterile hold it can be printed at desired interval, minimum of 1 minute. All undesired situation (faults) are to be printed at the time of fault generation. 6. CYCLE DATA STORAGE FACILITY: Historical cycle data gets stored in the memory of sterilizer which can be easily retrieved at will through USB. 7. QUICK HOT AIR DRYING SYSTEM: Specially designed drying valves have been provided to ensure each load comes out completely dry. 8. AUTOMATIC TEMPERATURE CONTROL SYSTEM: The sterilizer has automatic temperature control system which automatically maintains the desired temperature. 9. AIRTIGHT SEALING: Heavy Duty branded silicon gasket is provided for airtight seal. 10. FASTER COOLING: New rapid air-change convection cooling technique for faster cooling. 11. SS HEATING ELEMENTS: Stainless steel sheathed heating elements for reduced particle generation and longer life. 12. DESCRIPTION: a) Sterilization chamber are designed and built to conform to the most advanced technology and comply with international standards. b) Sterilization chamber in Stainless steel with argon welding. c) Chamber construction with full welding and rounded corners for easy cleaning it ensure classic hygiene. 13. HEPA FILTER: a) High temperature HEPA filters (0.3 micron, performance 99.97%) are installed in the circulation loop to ensure Class 100 environment in the chamber. b) Differential pressure indicators for monitoring performance of Hepa filter bank. c) Improved filter seating arrangement for maximum filter surface. 14. BAFFLE: New baffle design for uniform air flow and temperature uniformity between the top-bottom and sides of the sterilization Chamber. 15. SAFETY FEATURES: 15.1 EMERGENCY STOP: An Easily Accessible emergency stop is provided on main control panel door. 15.2 POWER FAILURE: Equipment settings will not get disturbed due to power failure and will not restart without human intervention. 15.3 FAILURE MODE DETECTION: Equipment indicate fault through audio / visual signal with details on Control panel/PLC (Failure mode detection). 15.4 INSULATION: The sterilizer is completely insulated to prevent any burns caused due to accidental contact to sterilizer body.

Brand Name : Steri

Material : Stainless Steel

Color : Silver

Automation Grade : Fully Automatic

Warranty : 1 Year

Country of Origin : India

...more

YSU-623 Dry Heat Sterilizer

1 Piece (MOQ)

Process Control and Other Features: 1. QUICK HOT AIR DRYING SYSTEM: Specially designed drying valves have been provided to ensure each load comes out completely dry. 2. AUTOMATIC TEMPERATURE CONTROL SYSTEM: The sterilizer has automatic temperature control system which automatically maintains the desired temperature. 3. AIRTIGHT SEALING: Heavy Duty branded silicon gasket is provided for airtight seal. 4. FASTER COOLING: New rapid air-change convection cooling technique for faster cooling. 5. SS HEATING ELEMENTS: Stainless steel sheathed heating elements for reduced particle generation and longer life. 6. DESCRIPTION: a) Sterilization chamber are designed and built to conform to the most advanced technology and comply with international standards. b) Sterilization chamber in Stainless steel with argon welding. c) Chamber construction with full welding and rounded corners for easy cleaning it ensure classic hygiene. 7. INSULATION: The sterilizer is completely insulated to prevent any burns caused due to accidental contact to sterilizer body.

Brand Name : Steri

Material : Stainless Steel

Color : Silver

Automation Grade : Automatic

Warranty : 1 Year

Country of Origin : India

...more

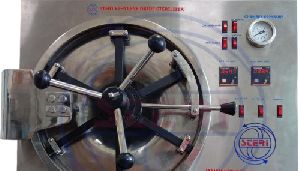

YSU-617A Fully Automatic Table Top Flash Autoclave

1 Piece (MOQ)

Required Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with fully automatic control system. Having each function (7+) of autoclave automated such as: a) Auto Pre Vacuum Pulsing b) Auto Ster c) Auto Exhaust d) Auto Vacuum Dry e) Auto Filter Air Dry f) Auto Fault Detection & Notification System g) Auto Shutdown 2. PRE-PROGAMMED CYCLES: The sterilizer has equipped 5 pre-programmed cycles as mentioned below: a) Liquid Cycle b) Packs Cycle c) Flexible Cycle d) Wrapped Cycle e) Unwrapped Cycle 3. USER CUSTOMIZABLE CYCLE: The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings. 4. PASSWORD PROTECTION: a) The sterilizer settings are password protected. b) The date and time settings are password protected, and User is able to update date and time settings on the screen for better record keeping. 5. OPTIONAL PRINTING FACILITY: a) The user is record the progress of the sterilization cycle in real time therefore online real time printing facility will be provided. b) The user can print the following details: Date and time of the cycle. Status of the cycle. Temperature at drain and chamber pressure at every event change and during sterile hold it can be printed at desired interval, minimum of 1 minute. All undesired situation (faults) are to be printed at the time of fault generation. Note:- Printer will be provided at extra cost with this model. 6. OPTIONAL CYCLE DATA STORAGE FACILITY: Historical cycle data gets stored in the memory of sterilizer which can be easily retrieved at will through USB. Note:- Optional cycle data storage facility will be provided at extra cost with this model. 7. STATE OF THE ART – VACUUM SYSTEM: Heavy Duty Branded- Oil free diaphragm type vacuum pump is provided to remove the air/gas from the chamber. 8. DOOR: The Sterilizer has manual sliding single door. Door frame is strong & robust enough to ensure smooth door movement & consistency in alignment. Door movement is smooth to ensure proper door alignment over a long period of time. 9. QUICK HOT AIR DRYING SYSTEM: Specially designed drying valves have been provided to ensure each load comes out completely dry. 11. AUTOMATIC TEMPERATURE DETECTION SYSTEM: The machine is equipped with temperature detection system and the user will be notified in case the machine fails to reach the set temperature or if the temperature over shoots. 12. AUTOMATIC LOW WATER CUT OFF SYSTEM: The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 13. AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 14. AIRTIGHT SEALING: Heavy duty branded silicon gasket will be provided for airtight seal. 15. SOLENOID VALVE: The sterilizer is equipped with branded solenoid valves for automatic process. 16. ANALOGUE GAUGES: a) The Sterilizer is fitted with branded NABH calibrated analogue chamber pressure (Compound) gauge to measure the pressure and vacuum of chamber. b) The Sterilizer is fitted with branded NABH calibrated analogue jacket pressure gauge to measure the jacket & boiler pressure. 17. EUROPEAN STYLE OUTER COVER: The sterilizer has fully covered design with panelling back and both the sides RHS & LHS. 18. SAFETY FEATURES: 18.1 AUTOMATIC FAULT DETECTION AND ALARM SYSTEM: The Machine is equipped with precision sensors capable of detecting various faults and notifying the user thereby making this a smart sterilizer: a) AUTOMATIC DUAL DOOR LOCK AND DETECTION SYSTEM: It is an inbuilt feature where In case the doors are not closed properly the sterilizer prevents the user from starting the cycle and visually notifies the same b) TEMPERATURE DETECTION SYSTEM: The user is notified in case the machine fails to reach the set temperature or if the temperature overshoots c) AUTOMATIC PRESSURE DETECTION AND MAINTENANCE: Chamber & Jacket pressure is maintained automatically. In case the pressure fails to reach the set value or if it drops the user is notified d) WATER DETECTION SYSTEM: The user will be notified in case the water level is not optimum for regular machine operation. e) AUTOMATIC ELECTRICITY ECONOMIZER: Once the temperature is reached or water level is not at optimum level the sterilizer will automatically cut off the heater system to save electricity. f) VACUUM LOCK DETECTION SYSTEM: this system detects the total vacuum generated and total time of vacuum maintained in chamber. It is also capable of detecting steam and air leakage. g) POWER CUT CYCLE RETENTION AND MANAGEMENT SYSTEM: the machine is equipped to deal with any power outages and based on the duration of the power outage the user is notified. 18.2 EMERGENCY STOP: An Easily Accessible emergency stop is provided on main control panel door. 18.3 POWER FAILURE: Equipment settings will not get disturbed due to power failure and will not restart without human intervention. 18.4 FAILURE MODE DETECTION: Equipment indicate fault through audio / visual signal with details on control panel/PLC (Failure mode detection). 18.5 HYDRAULIC TESTING: Complete sterilizer including chamber and piping are hydraulically tested at 2 times the working pressure. 18.6 INSULATION: The sterilizer is completely insulated to prevent any burns caused due to accidental contact to sterilizer body.

Brand Name : Steri

Material : Stainless Steel

Color : Silver

Warranty : 1 Year

Country of Origin : India

...more

YSU-615 Manual Surgical Scrub Station

1 Piece (MOQ)

Process Control and Other Features: 1. MANUAL KNEW OPERATED SYSTEM: Flow of water is controlled by Knew operated switch. 2. FOOT OPERATED SWITCH: Flow & quantity of liquid soap / disinfectant is controlled with the help of foot operated switch. 3. GEYSER SYSTEM: The machine is equipped with the geyser system. 4. WATER PUMP: The machine is fitted with the water pump. 5. AIR GUN SYSTEM: Scrub station is fitted with the air gun system for drying. 6. EUROPEAN STYLE FULLY COVERED: Scrub station is fully covered design with panelling Front, back and both the sides RHS & LHS. 7. WATER TANK WITH ACCESSORIES: The unit also consists of a SS 304 water tank, water heating system and water pump along with manual valves for hot and cold mixing. 8. SPECIAL DESIGNED: The complete unit is made of SS 304 (16 gauge) having rounded corners is provided for easy cleaning.

Brand Name : Steri

Material : Stainless Steel, SS 304

Color : Silver

Application : Hospital

Warranty : 1 Years

Country of Origin : India

...more

YSU-615 Fully Automatic Surgical Scrub Station

1 Piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with automatic control system. 2. AUTOMATIC PROXIMITY DETECTION SYSTEM: The unit is provided with advanced Proximity detection system that can sense the presence and allows controlled warm water to flow through electrically controlled solenoid valves and shuts off as soon as person is away from sensor. 3. MANUAL ELBOW OPERATED TAB: In case there is any unavailability of electricity for automatic controls, elbow operated taps are provided for washing. 4. FOOT OPERATED SWITCH: Flow & quantity of liquid soap / disinfectant is controlled with the help of foot operated switch. 5. GEYSER SYSTEM: The machine is equipped with the geyser system. 6. WATER PUMP: The machine is equipped with the water pump. 7. ELECTRIC SOLENOID VALVES: Scrub Station is equipped with branded electric solenoid valves for automatic process. 8. AIR GUN SYSTEM: Scrub station is fitted with the air gun system for drying. 9. WASHER JET: Scrub Station is equipped with washer jet for washing. & cleaning. 10. EUROPEAN STYLE FULLY COVERED: Scrub station is fully covered design with panelling Front, back and both the sides RHS & LHS. 11. WATER TANK WITH ACCESSORIES: The unit also consists of a SS 304 water tank, water heating system and water pump along with thermostat for heater control. This ensures that water is always available irrespective of low pressure. 12. SPECIAL DESIGNED: The complete unit is made of SS304 (16 gauge) having rounded corners and special flexible extendable washing spout is provided for easy cleaning.

Model Number : YSU-615

Brand Name : Steri

Material : SS 304

Color : Silver

Power Source : Electric

Type : Washing Equipment

Country of Origin : India

...more

YSU-613 Bowl Sterilizer

1 Piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC LOW WATER CUT OFF SYSTEM: The Sterilizer is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 2. AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 3. DOOR FEATURE: a) The sterilizer has SS 304 door with remote operated system. b) The sterilizer door is equipped with hydraulic lid which closes the sterilizer smoothly. 4. THERMOSTATICALLY CONTROLLED: The sterilizer is controlled by thermostatically. 5. INSTRUMENTS TRAY WITH HANGER SYSTEM: The sterilizer is equipped with the instruments tray and a hanger system to dip the instrument full inside water.

Brand Name : Steri

Material : Stainless Steel

Color : Silver

Warranty : 1 Years

Country of Origin : India

...more

YSU-611 Fully Automatic Rectangular Bio Medical Waste Sterilizer

1 piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with fully automatic control system. Having each function (10+) of autoclave automated such as: a) Auto Water Feeding b) Auto Pre Vacuum Pulsing c) Auto Ster d) Auto Slow Exhaust e) Auto Fast Exhaust f) Auto Vacuum Dry g) Auto Filter Air Dry h) Auto Door Locks i) Auto Fault Detection & Notification System j) Auto Shutdown 2. 6 PRE-PROGAMMED CYCLES: a) 4 Sterilization Cycles Instrument Cycle Liquid Cycle Fabric Cycle Customer Variable Cycle: The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings. b) 2 Test Cycles Bowie Dick Test Cycle Leak Test Cycle 3. AUTOMATIC WATER FEEDING SYSTEM: The Sterilizer has automatic water feeding system ensuring autoclave to run without any interruption. 4. AUTOMATICALLY DETECTS ANY CHAMBER LEAKAGE: The Machine automatically detects any air/steam leakage in chamber. The Machine automatically detects any steam penetration barriers, inadequate air removal. 5. OPTIONAL DATA STORAGE FACILITY: Historical cycle data gets stored in the memory of sterilizer which can be easily retrieved at will through USB. 6. OPTIONAL PRINTING FACILITY: a) The user can record the progress of the sterilization cycle in real time and print the following details: Date and Time of the cycle. Batch No. Cycle Selected Preset Cycle Parameter Status of the cycle Temperature and chamber pressure b) It is capable of printing at desired time interval, minimum of 1 minute c) All undesired situation (faults) are printed at the time of fault generation Note: - Printer is available at extra cost with this model. 5. POWERFUL TRIPLE DRYING SYSTEM:- a) WATER RING TYPE VACUUM PUMP: Machine is equipped with Water Ring Type Vacuum Pump for complete drying load in both automatic & manual mode. b) BACKUP VACUUM SYSTEM: Machine is equipped with Cutting edge venturi system for creating vacuum in manual mode. c) HOT AIR DRYING: Specially designed drying valves have been provided to ensure each load comes out completely dry. 6. SAFETY FEATURES: The sterilizer has various inbuilt safety feature which not only protects the user but also ensures the sterilizer is working as per design and identifies any inconsistency in the system. We have listed few such features below for your reference: 6.1 AUTOMATIC FAULT DETECTION AND ALARM SYSTEM: The Machine is equipped with precision sensors capable of detecting various faults and notifying the user thereby making this a smart sterilizer: a) AUTOMATIC DUAL DOOR LOCK AND DETECTION SYSTEM: It is an inbuilt feature where In case the doors are not closed properly the sterilizer prevents the user from starting the cycle and visually notifies the same b) TEMPERATURE DETECTION SYSTEM: The user is notified in case the machine fails to reach the set temperature or if the temperature overshoots c) AUTOMATIC PRESSURE DETECTION AND MAINTENANCE: Chamber & Jacket pressure is maintained automatically. In case the pressure fails to reach the set value or if it drops the user is notified d) WATER DETECTION SYSTEM: The user will be notified in case the water level is not optimum for regular machine operation. e) AUTOMATIC ELECTRICITY ECONOMIZER: Once the temperature is reached or water level is not at optimum level the sterilizer will automatically cut off the heater system to save electricity. f) VACUUM LOCK DETECTION SYSTEM: this system detects the total vacuum generated and total time of vacuum maintained in chamber. It is also capable of detecting steam and air leakage. g) POWER CUT CYCLE RETENTION AND MANAGEMENT SYSTEM: the machine is equipped to deal with any power outages and based on the duration of the power outage the user is notified. 6.2 PASSWORD PROTECTION: a) The sterilizer settings are password protected. b) The date and time settings are password protected, and User is able to update date and time settings on the screen for better record keeping. 6.3 EMERGENCY STOP: An Easily Accessible emergency stop is provided on main control panel door. 6.4 POWER FAILURE: Equipment settings will not get disturbed due to power failure and will not restart without human intervention. 6.5 HYDRAULICALY TESTED: Complete sterilizer including chamber, jacket, and piping are hydraulically tested at 2 times the working pressure. 6.6 AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 6.7 AUTOMATIC SHUT OFF VALVE: Prevents hazardous leakage of hot steam and boiled water due to breakage of glass tube. 6.8 AUTOMATIC VACUUM BREAKER: The sterilizer is fitted with vacuum breaker system to prevent collapsing of jacket due to vacuum formed by condensation of steam. 6.9 AUTOMATIC LOW WATER CUT OFF SYSTEM: The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 6.10 AUTOMATIC DUAL DOOR LOCKING SYSTEM: a) AUTOMATIC ELECTRONIC DOOR LOCK: The sterilizer is fitted automatic electronic door locking mechanism system. a) AUTOMATIC MECHANICAL DOOR LOCK: The sterilizer is equipped with automatic mechanical door locking system which prevents the user to open the door until the atmospheric pressure is achieved inside the chamber. 6.11 DUAL SAFETY VALVE: The sterilizer is fitted with spring loaded dual safety valves. 6.12 HEAT PROTECTION: The sterilizer is completely insulated with chloride face mineral glass wool to prevent any burns caused due to accidental contact to sterilizer body. 6.13 STEAM LEAKAGE PROTECTION: Heavy duty branded silicon gasket is provided for airtight seal to prevent any leakage of steam. 6.14 NABH CALIBRATED GAUGES: All our gauges including pressure, compound and digital temperature gauge are calibrated & certified by Indian most trusted NABH lab certified. 7. SEPARATE STEAM GENERATOR: The sterilizer has separate steam generator with manual water feed control valve, separate manual valve for water drain and water level indicator. 8. PRE VACUUM STERILIZATION: All the air leaving the sterilizer prior to sterilization is treated in an secondary thermal chamber making the air sterile. 9. THERMAL STERILIZATION: High temperature steam comes in contact with air leaving the chamber and then passes through high temperature effective heat exchanger which makes the air sterile and safe. 10. WATER LEVEL INDICATOR: The sterilizer is fitted with water level gauge glass to indicate the water level. 11. EXTRA PORT FOR CALIBRATION AND VALIDATION: The sterilizer is equipped with external port for the sterilizer calibration and validation. 12. FLUSH MOUNTING: The machine is equipped with SS 304 flush mounting only (Front side) Non-Sterile side.

Brand Name : Steri

Material : Stainless Steel

Driven Type : Electric

Color : Grey

Automation Grade : Fully Automatic

Warranty : 2 Year

Country of Origin : India

...more

YSU-611 Fully Automatic Bio Medical Waste Sterilizer

1 piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with fully automatic control system. Having each function (10+) of autoclave automated such as: a) Auto Water Feeding b) Auto Pre Vacuum Pulsing c) Auto Ster d) Auto Slow Exhaust e) Auto Fast Exhaust f) Auto Vacuum Dry g) Auto Filter Air Dry h) Auto Door Locks i) Auto Fault Detection & Notification System j) Auto Shutdown 2. 6 PRE-PROGAMMED CYCLES: a) 4 Sterilization Cycles Instrument Cycle Liquid Cycle Fabric Cycle Customer Variable Cycle: The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings. b) 2 Test Cycles Bowie Dick Test Cycle Leak Test Cycle 3. AUTOMATIC WATER FEEDING SYSTEM: The Sterilizer has automatic water feeding system ensuring autoclave to run without any interruption. 4. AUTOMATICALLY DETECTS ANY CHAMBER LEAKAGE: The Machine automatically detects any air/steam leakage in chamber. The Machine automatically detects any steam penetration barriers, inadequate air removal. 5. OPTIONAL DATA STORAGE FACILITY: Historical cycle data gets stored in the memory of sterilizer which can be easily retrieved at will through USB. 6. OPTIONAL PRINTING FACILITY: a) The user can record the progress of the sterilization cycle in real time and print the following details: Date and Time of the cycle. Batch No. Cycle Selected Preset Cycle Parameter Status of the cycle Temperature and chamber pressure b) It is capable of printing at desired time interval, minimum of 1 minute c) All undesired situation (faults) are printed at the time of fault generation Note: - Printer is available at extra cost with this model. 5. POWERFUL TRIPLE DRYING SYSTEM:- a) WATER RING TYPE VACUUM PUMP: Machine is equipped with Water Ring Type Vacuum Pump for complete drying load in both automatic & manual mode. b) BACKUP VACUUM SYSTEM: Machine is equipped with Cutting edge venturi system for creating vacuum in manual mode. c) HOT AIR DRYING: Specially designed drying valves have been provided to ensure each load comes out completely dry. 6. SAFETY FEATURES: The sterilizer has various inbuilt safety feature which not only protects the user but also ensures the sterilizer is working as per design and identifies any inconsistency in the system. We have listed few such features below for your reference: 6.1 AUTOMATIC FAULT DETECTION AND ALARM SYSTEM: The Machine is equipped with precision sensors capable of detecting various faults and notifying the user thereby making this a smart sterilizer: a) AUTOMATIC DUAL DOOR LOCK AND DETECTION SYSTEM: It is an inbuilt feature where In case the doors are not closed properly the sterilizer prevents the user from starting the cycle and visually notifies the same b) TEMPERATURE DETECTION SYSTEM: The user is notified in case the machine fails to reach the set temperature or if the temperature overshoots c) AUTOMATIC PRESSURE DETECTION AND MAINTENANCE: Chamber & Jacket pressure is maintained automatically. In case the pressure fails to reach the set value or if it drops the user is notified d) WATER DETECTION SYSTEM: The user will be notified in case the water level is not optimum for regular machine operation. e) AUTOMATIC ELECTRICITY ECONOMIZER: Once the temperature is reached or water level is not at optimum level the sterilizer will automatically cut off the heater system to save electricity. f) VACUUM LOCK DETECTION SYSTEM: this system detects the total vacuum generated and total time of vacuum maintained in chamber. It is also capable of detecting steam and air leakage. g) POWER CUT CYCLE RETENTION AND MANAGEMENT SYSTEM: the machine is equipped to deal with any power outages and based on the duration of the power outage the user is notified. 6.2 PASSWORD PROTECTION: a) The sterilizer settings are password protected. b) The date and time settings are password protected, and User is able to update date and time settings on the screen for better record keeping. 6.3 EMERGENCY STOP: An Easily Accessible emergency stop is provided on main control panel door. 6.4 POWER FAILURE: Equipment settings will not get disturbed due to power failure and will not restart without human intervention. 6.5 HYDRAULICALY TESTED: Complete sterilizer including chamber, jacket, and piping are hydraulically tested at 2 times the working pressure. 6.6 AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 6.7 AUTOMATIC SHUT OFF VALVE: Prevents hazardous leakage of hot steam and boiled water due to breakage of glass tube. 6.8 AUTOMATIC VACUUM BREAKER: The sterilizer is fitted with vacuum breaker system to prevent collapsing of jacket due to vacuum formed by condensation of steam. 6.9 AUTOMATIC LOW WATER CUT OFF SYSTEM: The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 6.10 AUTOMATIC DUAL DOOR LOCKING SYSTEM: a) AUTOMATIC ELECTRONIC DOOR LOCK: The sterilizer is fitted automatic electronic door locking mechanism system. a) AUTOMATIC MECHANICAL DOOR LOCK: The sterilizer is equipped with automatic mechanical door locking system which prevents the user to open the door until the atmospheric pressure is achieved inside the chamber. 6.11 DUAL SAFETY VALVE: The sterilizer is fitted with spring loaded dual safety valves. 6.12 HEAT PROTECTION: The sterilizer is completely insulated with chloride face mineral glass wool to prevent any burns caused due to accidental contact to sterilizer body. 6.13 STEAM LEAKAGE PROTECTION: Heavy duty branded silicon gasket is provided for airtight seal to prevent any leakage of steam. 6.14 NABH CALIBRATED GAUGES: All our gauges including pressure, compound and digital temperature gauge are calibrated & certified by Indian most trusted NABH lab certified. 7. SEPARATE STEAM GENERATOR: The sterilizer has separate steam generator with manual water feed control valve, separate manual valve for water drain and water level indicator. 8. PRE VACUUM STERILIZATION: All the air leaving the sterilizer prior to sterilization is treated in an secondary thermal chamber making the air sterile. 9. THERMAL STERILIZATION: High temperature steam comes in contact with air leaving the chamber and then passes through high temperature effective heat exchanger which makes the air sterile and safe. 10. WATER LEVEL INDICATOR: The sterilizer is fitted with water level gauge glass to indicate the water level. 11. EXTRA PORT FOR CALIBRATION AND VALIDATION: The sterilizer is equipped with external port for the sterilizer calibration and validation. 12. FLUSH MOUNTING: The machine is equipped with SS 304 flush mounting only (Front side) Non-Sterile side.

Brand Name : Steri

Material : Stainless Steel

Driven Type : Electric

Automation Grade : Automatic

Warranty : 2 Year

Country of Origin : India

...more

YSU-608 Silver Fully Automatic Horizontal High Pressure Steam Sterilizer

1 Piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with 5 automatic control function controlled by Pre-programmed 4.2” Coloured Touch Screen Display. a) Auto Ster b) Auto Exhaust c) Auto Vacuum Dry d) Auto Air Dry e) Auto Water Feeding 2. PRE-PROGAMMED CYCLES: The sterilizer comes with 4 pre-programmed sterilization cycles as mentioned below: a) Instrument Cycle b) Fabric Cycle c) Liquid Cycle d) Customer Variable Cycle The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings. 3. AUTOMATIC WATER FEEDING SYSTEM: The Sterilizer has automatic water feeding system ensuring autoclave to run without any interruption. 4. PRINTING FACILITY: a) The user is record the progress of the sterilization cycle in real time therefore online real time printing facility will be provided. b) The user can print the following details: Date and time of the cycle. Status of the cycle. Temperature at drain and chamber pressure at every event change and during sterile hold are printed. 5. STATE OF THE ART – VACUUM SYSTEM:- a) Venture vacuum device is provided to create high vacuum pressure leading to dry loads on completion of sterilization. b) The Sterilizer has quick dry ejector for create high vacuum. Note:- Vacuum pump available at an extra cost. 6. SAFETY FEATURES: 6.1 HYDRAULICALY TESTED: Complete sterilizer including chamber, jacket, and piping are hydraulically tested at 2 times the working pressure. 6.2 AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 6.3 AUTOMATIC SHUT OFF VALVE: Prevents hazardous leakage of hot steam and boiled water due to breakage of glass tube. 6.4 AUTOMATIC VACUUM BREAKER: The sterilizer is fitted with vacuum breaker system to prevent collapsing of jacket due to vacuum formed by condensation of steam. 6.5 AUTOMATIC LOW WATER CUT OFF SYSTEM: The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 6.6 AUTOMATIC MECHANICAL DOOR LOCKING SYSTEM: The sterilizer is equipped with automatic mechanical door locking system which prevents the user to open the door until the atmospheric pressure is achieved inside the chamber. 6.7 DUAL SAFETY VALVE: The sterilizer is fitted with spring loaded dual safety valves. 6.8 HEAT PROTECTION: The sterilizer is completely insulated with chloride face mineral glass wood to prevent any burns caused due to accidental contact to sterilizer body. 6.9 STEAM LEAKAGE PROTECTION: Heavy Duty branded silicon gasket is provided for airtight seal to prevent any leakage of steam. 6.10 NABH CALIBRATED GAUGES: All our gauges including pressure, compound and temperature are calibrated & certified by Indian most trusted NABH lab certified. 7. SEPARATE STEAM GENERATOR: The sterilizer has separate steam generator with manual water feed control valve, separate manual valve for water drain and water level indicator. 8. WATER LEVEL INDICATOR: The sterilizer is fitted with water level gauge glass to indicate the water level. 9. VALIDATION PORT: The sterilizer is equipped with external validation port for the sterilizer calibration.

Automation Grade : Fully Automatic

Brand Name : Steri

Material : Stainless Steel

Pressure : High Pressure

Usage : Industrial Use

Warranty : 2 Year

Country of Origin : India

...more

YSU-608 Platinum Plus Horizontal High Pressure Vacuum Steam Sterilizer

1 Piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with fully automatic control system. Having each function (10+) of autoclave automated such as: a) Auto Water Feeding b) Auto Pre Vacuum Pulsing c) Auto Ster d) Auto Slow Exhaust e) Auto Fast Exhaust f) Auto Vacuum Dry g) Auto Filter Air Dry h) Auto Door Locks i) Auto Fault Detection & Notification System j) Auto Shutdown 2. 8 PRE-PROGAMMED CYCLES: a) 6 Sterilization Cycles Instrument Cycle Wrapped Cycle Gravity Cycle Liquid Cycle Fabric Cycle Customer Variable Cycle: The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings. b) 2 Test Cycles Bowie Dick Test Cycle Leak Test Cycle 3. AUTOMATIC WATER FEEDING SYSTEM: The Sterilizer has automatic water feeding system ensuring autoclave to run without any interruption. 4. DATA STORAGE FACILITY: Historical cycle data gets stored in the memory of sterilizer which can be easily retrieved at will through USB. 5. PRINTING FACILITY: a) The user can record the progress of the sterilization cycle in real time and print the following details: Date and Time of the cycle. Batch No. Cycle Selected Preset Cycle Parameter Status of the cycle Temperature and chamber pressure b) It is capable of printing at desired time interval, minimum of 1 minute. c) All undesired situation (faults) are printed at the time of fault generation. 5. POWERFUL TRIPLE DRYING SYSTEM:- a) WATER RING TYPE VACUUM PUMP: Machine is equipped with Water Ring Type Vacuum Pump for complete drying load in both automatic & manual mode. b) BACKUP VACUUM SYSTEM: Machine is equipped with Cutting edge venturi system for creating vacuum in manual mode. c) HOT AIR DRYING: Specially designed drying valves have been provided to ensure each load comes out completely dry. 6. SAFETY FEATURES: The sterilizer has various inbuilt safety feature which not only protects the user but also ensures the sterilizer is working as per design and identifies any inconsistency in the system. We have listed few such features below for your reference: 6.1 AUTOMATIC FAULT DETECTION AND ALARM SYSTEM: The Machine is equipped with precision sensors capable of detecting various faults and notifying the user thereby making this a smart sterilizer: a) AUTOMATIC DUAL DOOR LOCK AND DETECTION SYSTEM: It is an inbuilt feature where In case the doors are not closed properly the sterilizer prevents the user from starting the cycle and visually notifies the same b) TEMPERATURE DETECTION SYSTEM: The user is notified in case the machine fails to reach the set temperature or if the temperature overshoots c) AUTOMATIC PRESSURE DETECTION AND MAINTENANCE: Chamber & Jacket pressure is maintained automatically. In case the pressure fails to reach the set value or if it drops the user is notified d) WATER DETECTION SYSTEM: The user will be notified in case the water level is not optimum for regular machine operation. e) AUTOMATIC ELECTRICITY ECONOMIZER: Once the temperature is reached or water level is not at optimum level the sterilizer will automatically cut off the heater system to save electricity. f) VACUUM LOCK DETECTION SYSTEM: this system detects the total vacuum generated and total time of vacuum maintained in chamber. It is also capable of detecting steam and air leakage. g) POWER CUT CYCLE RETENTION AND MANAGEMENT SYSTEM: the machine is equipped to deal with any power outages and based on the duration of the power outage the user is notified. 6.2 PASSWORD PROTECTION: a) The sterilizer settings are password protected. b) The date and time settings are password protected, and User is able to update date and time settings on the screen for better record keeping. 6.3 EMERGENCY STOP: An Easily Accessible emergency stop is provided on main control panel door. 6.4 POWER FAILURE: Equipment settings will not get disturbed due to power failure and will not restart without human intervention. 6.5 HYDRAULICALY TESTED: Complete sterilizer including chamber, jacket, and piping are hydraulically tested at 2 times the working pressure. 6.6 AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 6.7 AUTOMATIC SHUT OFF VALVE: Prevents hazardous leakage of hot steam and boiled water due to breakage of glass tube. 6.8 AUTOMATIC VACUUM BREAKER: The sterilizer is fitted with vacuum breaker system to prevent collapsing of jacket due to vacuum formed by condensation of steam. 6.9 AUTOMATIC LOW WATER CUT OFF SYSTEM: The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 6.10 AUTOMATIC ELECTRONIC DOOR LOCKING SYSTEM: The sterilizer is fitted automatic electronic door locking mechanism system. 6.11 DUAL SAFETY VALVE: The sterilizer is fitted with spring loaded dual safety valves. 6.12 HEAT PROTECTION: The sterilizer is completely insulated with chloride face mineral glass wool to prevent any burns caused due to accidental contact to sterilizer body. 6.13 STEAM LEAKAGE PROTECTION: Heavy duty branded silicon gasket is provided for airtight seal to prevent any leakage of steam. 6.14 NABH CALIBRATED GAUGES: All our gauges including pressure, compound and digital temperature gauge are calibrated & certified by Indian most trusted NABH lab certified. 7. SEPARATE STEAM GENERATOR: The sterilizer has separate steam generator with manual water feed control valve, separate manual valve for water drain and water level indicator. 8. WATER LEVEL INDICATOR: The sterilizer is fitted with water level gauge glass to indicate the water level. 9. EXTRA PORT FOR CALIBRATION AND VALIDATION: The sterilizer is equipped with external port for the sterilizer calibration and validation. 10. EUROPIAN STYLE PANELLING: The sterilizer is fully covered with SS 304 panelling on all sides for complete protection.

Automation Grade : Fully Automatic

Brand Name : Steri

Material : Stainless Steel

Color : Grey

Pressure : High Pressure

Usage : Industrial Use

Warranty : 2 Year

Country of Origin : India

...more

YSU-608 Platinum Horizontal High Pressure Vacuum Steam Sterilizer

1 Piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with fully automatic control system. Having each function (10+) of autoclave automated such as: a) Auto Water Feeding b) Auto Pre Vacuum Pulsing c) Auto Ster d) Auto Slow Exhaust e) Auto Fast Exhaust f) Auto Vacuum Dry g) Auto Filter Air Dry h) Auto Door Locks i) Auto Fault Detection & Notification System j) Auto Shutdown 2. 8 PRE-PROGAMMED CYCLES: a) 6 Sterilization Cycles Instrument Cycle Wrapped Cycle Gravity Cycle Liquid Cycle Fabric Cycle Customer Variable Cycle: The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings. b) 2 Test Cycles Bowie Dick Test Cycle Leak Test Cycle 3. AUTOMATIC WATER FEEDING SYSTEM: The Sterilizer has automatic water feeding system ensuring autoclave to run without any interruption. 4. DATA STORAGE FACILITY: Historical cycle data gets stored in the memory of sterilizer which can be easily retrieved at will through USB. 5. PRINTING FACILITY: a) The user can record the progress of the sterilization cycle in real time and print the following details: Date and Time of the cycle. Batch No. Cycle Selected Preset Cycle Parameter Status of the cycle Temperature and chamber pressure b) It is capable of printing at desired time interval, minimum of 1 minute. c) All undesired situation (faults) are printed at the time of fault generation. 5. POWERFUL TRIPLE DRYING SYSTEM:- a) WATER RING TYPE VACUUM PUMP: Machine is equipped with Water Ring Type Vacuum Pump for complete drying load in both automatic & manual mode. b) BACKUP VACUUM SYSTEM: Machine is equipped with Cutting edge venturi system for creating vacuum in manual mode. c) HOT AIR DRYING: Specially designed drying valves have been provided to ensure each load comes out completely dry. 6. SAFETY FEATURES: The sterilizer has various inbuilt safety feature which not only protects the user but also ensures the sterilizer is working as per design and identifies any inconsistency in the system. We have listed few such features below for your reference: 6.1 AUTOMATIC FAULT DETECTION AND ALARM SYSTEM: The Machine is equipped with precision sensors capable of detecting various faults and notifying the user thereby making this a smart sterilizer: a) AUTOMATIC DUAL DOOR LOCK AND DETECTION SYSTEM: It is an inbuilt feature where In case the doors are not closed properly the sterilizer prevents the user from starting the cycle and visually notifies the same b) TEMPERATURE DETECTION SYSTEM: The user is notified in case the machine fails to reach the set temperature or if the temperature overshoots c) AUTOMATIC PRESSURE DETECTION AND MAINTENANCE: Chamber & Jacket pressure is maintained automatically. In case the pressure fails to reach the set value or if it drops the user is notified d) WATER DETECTION SYSTEM: The user will be notified in case the water level is not optimum for regular machine operation. e) AUTOMATIC ELECTRICITY ECONOMIZER: Once the temperature is reached or water level is not at optimum level the sterilizer will automatically cut off the heater system to save electricity. f) VACUUM LOCK DETECTION SYSTEM: this system detects the total vacuum generated and total time of vacuum maintained in chamber. It is also capable of detecting steam and air leakage. g) POWER CUT CYCLE RETENTION AND MANAGEMENT SYSTEM: the machine is equipped to deal with any power outages and based on the duration of the power outage the user is notified. 6.2 PASSWORD PROTECTION: a) The sterilizer settings are password protected. b) The date and time settings are password protected, and User is able to update date and time settings on the screen for better record keeping. 6.3 EMERGENCY STOP: An Easily Accessible emergency stop is provided on main control panel door. 6.4 POWER FAILURE: Equipment settings will not get disturbed due to power failure and will not restart without human intervention. 6.5 HYDRAULICALY TESTED: Complete sterilizer including chamber, jacket, and piping are hydraulically tested at 2 times the working pressure. 6.6 AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 6.7 AUTOMATIC SHUT OFF VALVE: Prevents hazardous leakage of hot steam and boiled water due to breakage of glass tube. 6.8 AUTOMATIC VACUUM BREAKER: The sterilizer is fitted with vacuum breaker system to prevent collapsing of jacket due to vacuum formed by condensation of steam. 6.9 AUTOMATIC LOW WATER CUT OFF SYSTEM: The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 6.10 AUTOMATIC DUAL DOOR LOCKING SYSTEM: a) AUTOMATIC ELECTRONIC DOOR LOCK: The sterilizer is fitted automatic electronic door locking mechanism system. a) AUTOMATIC MECHANICAL DOOR LOCK: The sterilizer is equipped with automatic mechanical door locking system which prevents the user to open the door until the atmospheric pressure is achieved inside the chamber. 6.11 DUAL SAFETY VALVE: The sterilizer is fitted with spring loaded dual safety valves. 6.12 HEAT PROTECTION: The sterilizer is completely insulated with chloride face mineral glass wool to prevent any burns caused due to accidental contact to sterilizer body. 6.13 STEAM LEAKAGE PROTECTION: Heavy duty branded silicon gasket is provided for airtight seal to prevent any leakage of steam. 6.14 NABH CALIBRATED GAUGES: All our gauges including pressure, compound and digital temperature gauge are calibrated & certified by Indian most trusted NABH lab certified. 7. SEPARATE STEAM GENERATOR: The sterilizer has separate steam generator with manual water feed control valve, separate manual valve for water drain and water level indicator. 8. WATER LEVEL INDICATOR: The sterilizer is fitted with water level gauge glass to indicate the water level. 9. EXTRA PORT FOR CALIBRATION AND VALIDATION: The sterilizer is equipped with external port for the sterilizer calibration and validation. 10. EUROPIAN STYLE PANELLING: The sterilizer is fully covered with SS 304 panelling on all sides for complete protection.

Automation Grade : Automatic

Material : Stainless Steel

Shape : Rectangular

Color : Grey

Pressure : High Pressure

Usage : Industrial Use

Warranty : 1 Year

Country of Origin : India

...more

YSU-608 Gold Horizontal High Pressure Vacuum Double Door Steam Sterilizer

1 Piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with fully automatic control system. Having each function (10+) of autoclave automated such as: a) Auto Water Feeding b) Auto Pre Vacuum Pulsing c) Auto Ster d) Auto Slow Exhaust e) Auto Fast Exhaust f) Auto Vacuum Dry g) Auto Filter Air Dry h) Auto Door Locks i) Auto Fault Detection & Notification System j) Auto Shutdown 2. 6 PRE-PROGAMMED CYCLES: a) 4 Sterilization Cycles Instrument Cycle Liquid Cycle Fabric Cycle Customer Variable Cycle: The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings. b) 2 Test Cycles Bowie Dick Test Cycle Leak Test Cycle 3. AUTOMATIC WATER FEEDING SYSTEM: The Sterilizer has automatic water feeding system ensuring continuous running without interruption. 4. OPTIONAL DATA STORAGE FACILITY: Historical cycle data gets stored in the memory of sterilizer which can be easily retrieved at will through USB. Note: - Data storage facility is available at extra cost with this model. 5. OPTIONAL PRINTING FACILITY: a) The user can record the progress of the sterilization cycle in real time and print the following details: Date and Time of the cycle. Batch No. Cycle Selected Preset Cycle Parameter Status of the cycle Temperature and chamber pressure b) It is capable of printing at desired time interval, minimum of 1 minute c) All undesired situation (faults) are printed at the time of fault generation Note: - Printer is available at extra cost with this model. 5. POWERFUL TRIPLE DRYING SYSTEM:- a) WATER RING TYPE VACUUM PUMP: Machine is equipped with Water Ring Type Vacuum Pump for complete drying load in both automatic & manual mode. b) BACKUP VACUUM SYSTEM: Machine is equipped with Cutting edge venturi system for creating vacuum in manual mode. c) HOT AIR DRYING: Specially designed drying valves have been provided to ensure each load comes out completely dry. 6. SAFETY FEATURES: The sterilizer has various inbuilt safety feature which not only protects the user but also ensures the sterilizer is working as per design and identifies any inconsistency in the system. We have listed few such features below for your reference: 6.1 AUTOMATIC FAULT DETECTION AND ALARM SYSTEM: The Machine is equipped with precision sensors capable of detecting various faults and notifying the user thereby making this a smart sterilizer: a) AUTOMATIC DUAL DOOR LOCK AND DETECTION SYSTEM: It is an inbuilt feature where In case the doors are not closed properly the sterilizer prevents the user from starting the cycle and visually notifies the same b) TEMPERATURE DETECTION SYSTEM: The user is notified in case the machine fails to reach the set temperature or if the temperature overshoots c) AUTOMATIC PRESSURE DETECTION AND MAINTENANCE: Chamber & Jacket pressure is maintained automatically. In case the pressure fails to reach the set value or if it drops the user is notified d) WATER DETECTION SYSTEM: The user will be notified in case the water level is not optimum for regular machine operation. e) AUTOMATIC ELECTRICITY ECONOMIZER: Once the temperature is reached or water level is not at optimum level the sterilizer will automatically cut off the heater system to save electricity. f) VACUUM LOCK DETECTION SYSTEM: this system detects the total vacuum generated and total time of vacuum maintained in chamber. It is also capable of detecting steam and air leakage. g) POWER CUT CYCLE RETENTION AND MANAGEMENT SYSTEM: the machine is equipped to deal with any power outages and based on the duration of the power outage the user is notified. 6.2 PASSWORD PROTECTION: a) The sterilizer settings are password protected. b) The date and time settings are password protected and User is able to update date and time settings on the screen for better record keeping. 6.3 EMERGENCY STOP: An Easily Accessible emergency stop is provided on main control panel door. 6.5 HYDRAULICALY TESTED: Complete sterilizer including chamber, jacket, and piping are hydraulically tested at 2 times the working pressure. 6.6 AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 6.7 AUTOMATIC SHUT OFF VALVE: Prevents hazardous leakage of hot steam and boiled water due to breakage of glass tube. 6.8 AUTOMATIC VACUUM BREAKER: The sterilizer is fitted with vacuum breaker system to prevent collapsing of jacket due to vacuum formed by condensation of steam. 6.9 AUTOMATIC LOW WATER CUT OFF SYSTEM: The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 6.10 AUTOMATIC DUAL DOOR LOCKING SYSTEM: a) AUTOMATIC ELECTRONIC DOOR LOCK: The sterilizer is fitted automatic electronic door locking system. a) AUTOMATIC MECHANICAL DOOR LOCK: The sterilizer is equipped with automatic mechanical door locking system which prevents the user to open the door until the atmospheric pressure is achieved inside the chamber. 6.11 DUAL SAFETY VALVE: The sterilizer is fitted with pop up type dual safety valves. 6.12 HEAT PROTECTION: The sterilizer is completely insulated with chloride free mineral glass wool to prevent any burns caused due to accidental contact to sterilizer body. 6.13 STEAM LEAKAGE PROTECTION: Heavy duty branded silicon gasket is provided for airtight seal to prevent any leakage of steam. 6.14 NABH CALIBRATED GAUGES: All our gauges including pressure, compound and digital temperature gauge are calibrated & validated by India’s most trusted NABH certified lab. 7. SEPARATE STEAM GENERATOR: The sterilizer has separate steam generator with manual water feed control valve, separate manual valve for water drain and water level indicator. 8. WATER LEVEL INDICATOR: The sterilizer is fitted with water level gauge glass to indicate the water level. 9. EXTRA PORT FOR CALIBRATION AND VALIDATION: The sterilizer is equipped with external port for the sterilizer calibration and validation. 10. FLUSH MOUNTING: The machine is equipped with SS 304 flush mounting only (Front side) Non-Sterile side.

Automation Grade : Fully Automatic

Brand Name : Steri

Material : Stainless Steel

Color : Grey

Pressure : High Pressure

Usage : Industrial Use

Warranty : 2 Year

Country of Origin : India

...more

YSU-606 Table Top ETO Gas Sterilizer

1 Piece (MOQ)

Ethylene Oxide (EO or ETO) Gas is a crucial method for sterilizing delicate items like plastics, optics, and electronics, which are sensitive to high temperatures and radiation. Operating within the range of 30°C to 60°C, with humidity levels above 30% and gas concentrations between 200 and 800 mg/l, this treatment typically spans a minimum of three hours. Renowned for its exceptional penetration abilities, ETO effectively eliminates viruses, bacteria, fungi, and even spores, rendering it compatible with various materials, including medical devices. However, its usage entails significant risks due to its flammable, toxic, and carcinogenic properties. Ethylene oxide sterilization hinges on four pivotal factors: gas concentration, humidity, temperature, and duration. By disrupting the DNA of microorganisms, ETO halts their reproduction, ensuring consistent delivery of safe and sterile products to the market. Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with automatic control system by Pre-programmed PLC. Note:- Dual (Automatic & Manual operating) control system will beprovided at extra cost with this model. 2. PRE-PROGAMMED CYCLES: The sterilizer has equipped 4 pre-programmed cycles as mentioned below: a) 3 Cartridge Cycles: Warm Cycle Cold Cycle Customer Flexible Cycle b) 1 Cylinder Cycle. 3. PASSWORD PROTECTION: a) The sterilizer settings are password protected. b) The date and time settings are password protected, and User is able to update date and time settings on the screen for better record keeping. 4. FULLY AUTOMATIC OPERATION NEGATIVE PRESSURE CYCLE (100% ETO CARTRIDGE) CYCLE DESCRIPTION: a) Vacuuming of chamber to set value b) Leak hold period c) Cartridge punching /gas purging depending on the cycle selected d) Sterilization hold period for set time e) Exhaust and aeration for no. of aeration pulses set 5. EACH CYCLE FOLLOWS THE BELOW MENTIONED PHASES: a) CONDITIONING: Chambers are heated by electrical resistance or by steam contained in a jacket surrounding the chamber. b) INITIAL EVACUATION: To safely deliver the 100% ethylene oxide process, at least 97 percent of the air is removed from the chamber and is achieved byperforming a series of partial vacuums and pulling deep vacuum using vacuum pump. c) HUMIDIFICATION: This is accomplished by adding humidity in the form of steam injections after the addition of steam, the product is allowed to dwell or soak for time required to replace the moisture lost from the evacuation phase. d) EXPOSURE (STERILIZING): liquid ethylene oxide is first heated into a gaseous phase, then injected into the chamber. e) EXHAUST/DEGASSING: After the exposure phase of the process, all gas are removed from the chamber until the levels of EO fall below the flammable limit for the gas (3 percent or 30,000 ppm). a) AERATION: The sterilized contents are aerated to remove ETO residue withinthe sterilizer chamber. 6. AUTOMATIC FAULT DETECTION SYSTEM: a) The Machine is equipped with Faulty Sensor Detection system and user is visually notified of the same. b) The machine is equipped with temperature detection system and the user will be notified in case the machine fails to reach the set temperature or if the temperature overshoots c) The machine is equipped with water detection system. The user will be notified in case the water level is not optimum for regular machine operation. 7. PRINTER: a) The user is record the progress of the sterilization cycle in real time therefore online real time printing facility will be provided. b) The user can print the following details: Date and time of the cycle. Status of the cycle. Temperature at drain and chamber pressure at every event change and during sterile hold it can be printed at desired interval, minimum of 1 minute. All undesired situation (faults) are to be printed at the time of fault generation. 8. CYCLE DATA STORAGE FACILITY: Historical cycle data gets stored in the memory of sterilizer which can be easily retrieved at will through USB. 9. STATE OF THE ART – VACUUM SYSTEM: Heavy Duty Branded- Oil free diaphragm type vacuum pump is provided to remove the air/gas from the chamber. 10. AUTOMATIC HUMIDIFICATION SYSTEM: The machine is equipped with inbuilt automatic humidification system and is able to maintain humidity in the chamber within the range of 80 to 85% automatically controlled by wet and dry humidity transducer system. 11. AUTOMATIC LOW WATER CUT OFF SYSTEM: The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 12. AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 13. AIRTIGHT SEALING: Heavy Duty branded silicon gasket will be provided for airtight seal. 14. PNEUMATIC VALVE: The sterilizer is equipped with branded pneumatic valves for automatic process. 15. ANALOGUE GAUGES: The Sterilizer is fitted with branded NABH calibrated analogue chamber pressure (Compound) gauge to measure the pressure and vacuum of chamber. 16. CHAMBER TEMPERATURE CONTROLLER: The Sterilizer is fitted with chamber temperature controller to control the chambertemperature. 17. HUMIDIFICATION TEMPERATURE CONTROLLER: The Sterilizer is fitted with humidification temperature controller to control thechamber temperature. 18. CATALYTIC EXHAUST CONVERTER: Catalytic convertor is provided to treat the ETO gas before exhaust. 19. FLUSH MOUNTING: The machine is equipped with SS 304 flush mounting only (Front side) Non-Sterile side. 20. EUROPIAN STYLE PANELLING: The sterilizer has fully covered design with panelling back and both the sides RHS & LHS. 21. DOOR FEATURE: a) The sterilizer has single door with wing nut locking system. b) Door opening safety: Door will be open only at the end of cycle and only when chamber is at room pressure and desired chamber temperature is reached. 22. SAFETY FEATURES: 22.1 EMERGENCY STOP: An Easily Accessible emergency stop is provided on main control panel door. 22.2 POWER FAILURE: Equipment settings will not get disturbed due to power failure and will not restart without human intervention. 22.3 FAILURE MODE DETECTION: Equipment indicate fault through audio / visual signal with details on Control panel/PLC (Failure mode detection). 22.4 HYDRAULIC TESTING: Complete sterilizer including chamber, jacket, and piping are hydraulically tested at 2 times the working pressure. 22.5 AUTOMATIC DUAL DOOR LOCKING SYSTEM: 5.a) AUTOMATIC ELECTRONIC DOOR LOCK: The sterilizer is fitted automatic electronic door locking mechanism system. 5.b) AUTOMATIC MECHANICAL DOOR LOCK: The sterilizer is equipped with automatic mechanical door locking system which prevents the user to open the door until the atmospheric pressure is achieved inside the chamber. 22.6 SAFETY VALVE: The sterilizer is fitted with pop up type dual safety valves. 22.7 INSULATION: The sterilizer is completely insulated to prevent any burns caused due to accidental contact to sterilizer body

Brand Name : Steri

Material : Stainless Steel

Country of Origin : India

...more

YSU-605 Platinum Plus High Pressure Vacuum Steam Sterilizer

1 Piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with fully automatic control system. Having each function (10+) of autoclave automated such as: a) Auto Water Feeding b) Auto Pre Vacuum Pulsing c) Auto Ster d) Auto Slow Exhaust e) Auto Fast Exhaust f) Auto Vacuum Dry g) Auto Filter Air Dry h) Auto Door Locks i) Auto Fault Detection & Notification System j) Auto Shutdown 2. 8 PRE-PROGAMMED CYCLES: a) 6 Sterilization Cycles Instrument Cycle Wrapped Cycle Gravity Cycle Liquid Cycle Fabric Cycle Customer Variable Cycle: The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings. b) 2 Test Cycles Bowie Dick Test Cycle Leak Test Cycle 3. AUTOMATIC WATER FEEDING SYSTEM: The Sterilizer has automatic water feeding system ensuring autoclave to run without any interruption. 4. DATA STORAGE FACILITY: Historical cycle data gets stored in the memory of sterilizer which can be easily retrieved at will through USB. 5. PRINTING FACILITY: a) The user can record the progress of the sterilization cycle in real time and print the following details: Date and Time of the cycle. Batch No. Cycle Selected Preset Cycle Parameter Status of the cycle Temperature and chamber pressure b) It is capable of printing at desired time interval, minimum of 1 minute c) All undesired situation (faults) are printed at the time of fault generation 6. POWERFUL TRIPLE DRYING SYSTEM:- a) WATER RING TYPE VACUUM PUMP: Machine is equipped with Water Ring Type Vacuum Pump for complete drying load in both automatic & manual mode. b) BACKUP VACUUM SYSTEM: Machine is equipped with Cutting edge venturi system for creating vacuum in manual mode. c) HOT AIR DRYING: Specially designed drying valves have been provided to ensure each load comes out completely dry. 7. SAFETY FEATURES: The sterilizer has various inbuilt safety feature which not only protects the user but also ensures the sterilizer is working as per design and identifies any inconsistency in the system. We have listed few such features below for your reference: 7.1 AUTOMATIC FAULT DETECTION AND ALARM SYSTEM: The Machine is equipped with precision sensors capable of detecting various faults and notifying the user thereby making this a smart sterilizer: a) AUTOMATIC DUAL DOOR LOCK AND DETECTION SYSTEM: It is an inbuilt feature where In case the doors are not closed properly the sterilizer prevents the user from starting the cycle and visually notifies the same b) TEMPERATURE DETECTION SYSTEM: The user is notified in case the machine fails to reach the set temperature or if the temperature overshoots c) AUTOMATIC PRESSURE DETECTION AND MAINTENANCE: Chamber & Jacket pressure is maintained automatically. In case the pressure fails to reach the set value or if it drops the user is notified d) WATER DETECTION SYSTEM: The user will be notified in case the water level is not optimum for regular machine operation. e) AUTOMATIC ELECTRICITY ECONOMIZER: Once the temperature is reached or water level is not at optimum level the sterilizer will automatically cut off the heater system to save electricity. f) VACUUM LOCK DETECTION SYSTEM: this system detects the total vacuum generated and total time of vacuum maintained in chamber. It is also capable of detecting steam and air leakage. g) POWER CUT CYCLE RETENTION AND MANAGEMENT SYSTEM: the machine is equipped to deal with any power outages and based on the duration of the power outage the user is notified. 7.2 PASSWORD PROTECTION: a) The sterilizer settings are password protected. b) The date and time settings are password protected, and User is able to update date and time settings on the screen for better record keeping. 7.3 EMERGENCY STOP: An Easily Accessible emergency stop is provided on main control panel door. 7.4 POWER FAILURE: Equipment settings will not get disturbed due to power failure and will not restart without human intervention. 7.5 HYDRAULICALY TESTED: Complete sterilizer including chamber, jacket, and piping are hydraulically tested at 2 times the working pressure. 7.6 AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 7.7 AUTOMATIC SHUT OFF VALVE: Prevents hazardous leakage of hot steam and boiled water due to breakage of glass tube. 7.8 AUTOMATIC VACUUM BREAKER: The sterilizer is fitted with vacuum breaker system to prevent collapsing of jacket due to vacuum formed by condensation of steam. 7.9 AUTOMATIC LOW WATER CUT OFF SYSTEM: The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 7.10 AUTOMATIC DUAL DOOR LOCKING SYSTEM: a) AUTOMATIC ELECTRONIC DOOR LOCK: The sterilizer is fitted automatic electronic door locking mechanism system. a) AUTOMATIC MECHANICAL DOOR LOCK: The sterilizer is equipped with automatic mechanical door locking system which prevents the user to open the door until the atmospheric pressure is achieved inside the chamber. 7.11 DUAL SAFETY VALVE: The sterilizer is fitted with spring loaded dual safety valves. 7.12 HEAT PROTECTION: The sterilizer is completely insulated with chloride face mineral glass wool to prevent any burns caused due to accidental contact to sterilizer body. 7.13 STEAM LEAKAGE PROTECTION: Heavy duty branded silicon gasket is provided for airtight seal to prevent any leakage of steam. 7.14 NABH CALIBRATED GAUGES: All our gauges including pressure, compound and digital temperature gauge are calibrated & certified by Indian most trusted NABH lab certified. 8. SEPARATE STEAM GENERATOR: The sterilizer has separate steam generator with manual water feed control valve, separate manual valve for water drain and water level indicator. 9. WATER LEVEL INDICATOR: The sterilizer is fitted with water level gauge glass to indicate the water level. 10. EXTRA PORT FOR CALIBRATION AND VALIDATION: The sterilizer is equipped with external port for the sterilizer calibration and validation. 11. EUROPIAN STYLE PANELLING: The sterilizer is fully covered with SS 304 panelling on all sides for complete protection.

Automation Grade : Automatic

Brand Name : Steri

Material : Stainless Steel

Color : Silver

Pressure : High Pressure

Usage : Industrial Use

Warranty : 2 Year

Country of Origin : India

...more

YSU-605 Platinum High Pressure Vacuum Steam Sterilizer

1 Piece (MOQ)

Process Control and Other Features: 1. AUTOMATIC CONTROL SYSTEM: The Machine is equipped with fully automatic control system. Having each function (10+) of autoclave automated such as: a) Auto Water Feeding b) Auto Pre Vacuum Pulsing c) Auto Ster d) Auto Slow Exhaust e) Auto Fast Exhaust f) Auto Vacuum Dry g) Auto Filter Air Dry h) Auto Door Locks i) Auto Fault Detection & Notification System j) Auto Shutdown 2. 6 PRE-PROGAMMED CYCLES: a) 4 Sterilization Cycles Instrument Cycle Liquid Cycle Fabric Cycle Customer Variable Cycle: The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings. b) 2 Test Cycles Bowie Dick Test Cycle Leak Test Cycle 3. AUTOMATIC WATER FEEDING SYSTEM: The Sterilizer has automatic water feeding system ensuring autoclave to run without any interruption OPTIONAL DATA STORAGE FACILITY: Historical cycle data gets stored in the memory of sterilizer which can be easily retrieved at will through USB. 4. OPTIONAL PRINTING FACILITY: a) The user can record the progress of the sterilization cycle in real time and print the following details: Date and Time of the cycle. Batch No. Cycle Selected Preset Cycle Parameter Status of the cycle Temperature and chamber pressure b) It is capable of printing at desired time interval, minimum of 1 minute c) All undesired situation (faults) are printed at the time of fault generation Note:-Printerisavailableatextracostwiththismodel. 5. POWERFUL TRIPLE DRYING SYSTEM:- a) WATER RING TYPE VACUUM PUMP: Machine is equipped with Water Ring Type Vacuum Pump for complete drying load in both automatic & manual mode. b) BACKUP VACUUM SYSTEM: Machine is equipped with Cutting edge venturi system for creating vacuum in manual mode. c) HOT AIR DRYING: Specially designed drying valves have been provided to ensure each load comes out completely dry. 6. SAFETY FEATURES: The sterilizer has various inbuilt safety feature which not only protects the user but also ensures the sterilizer is working as per design and identifies any inconsistency in the system. We have listed few such features below for your reference: 6.1 AUTOMATIC FAULT DETECTION AND ALARM SYSTEM: The Machine is equipped with precision sensors capable of detecting various faults and notifying the user thereby making this a smart sterilizer: 1.a) AUTOMATIC DUAL DOOR LOCK AND DETECTION SYSTEM: It is an inbuilt feature where In case the doors are not closed properly the sterilizer prevents the user from starting the cycle and visually notifies the same 1.b) TEMPERATURE DETECTION SYSTEM: The user is notified in case the machine fails to reach the set temperature or if the temperature overshoots 1.c) AUTOMATIC PRESSURE DETECTION AND MAINTENANCE: Chamber & Jacket pressure is maintained automatically. In case the pressure fails to reach the set value or if it drops the user is notified 1.d) WATER DETECTION SYSTEM: The user will be notified in case the water level is not optimum for regular machine operation. 1.e) AUTOMATIC ELECTRICITY ECONOMIZER: Once the temperature is reached or water level is not at optimum level the sterilizer will automatically cut off the heater system to save electricity. 1.f) VACUUM LOCK DETECTION SYSTEM: this system detects the total vacuum generated and total time of vacuum maintained in chamber. It is also capable of detecting steam and air leakage. 1.g) POWER CUT CYCLE RETENTION AND MANAGEMENT SYSTEM: the machine is equipped to deal with any power outages and based on the duration of the power outage the user is notified. 6.2 PASSWORD PROTECTION: 2.a) The sterilizer settings are password protected. 2.b) The date and time settings are password protected, and User is able to update date and time settings on the screen for better record keeping. 6.3 EMERGENCY STOP: An Easily Accessible emergency stop is provided on main control panel door. 6.4 POWER FAILURE: Equipment settings will not get disturbed due to power failure and will not restart without human intervention. 6.5 HYDRAULICALY TESTED: Complete sterilizer including chamber, jacket, and piping are hydraulically tested at 2 times the working pressure. 6.6 AUTOMATIC PRESSURE CONTROL SYSTEM: The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer. 6.7 AUTOMATIC SHUT OFF VALVE: Prevents hazardous leakage of hot steam and boiled water due to breakage of glass tube. 6.8 AUTOMATIC VACUUM BREAKER: The sterilizer is fitted with vacuum breaker system to prevent collapsing of jacket due to vacuum formed by condensation of steam. 6.9 AUTOMATIC LOW WATER CUT OFF SYSTEM: The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation. 6.10 AUTOMATIC DUAL DOOR LOCKING SYSTEM: 10.a) AUTOMATIC ELECTRONIC DOOR LOCK: The sterilizer is fitted automatic electronic door locking mechanism system. a)AUTOMATIC MECHANICAL DOOR LOCK: The sterilizer is equipped with automatic mechanical door locking system which prevents the user to open the door until the atmospheric pressure is achieved inside the chamber. 6.10 AUTOMATIC DUAL DOOR LOCKING SYSTEM: 10.a) AUTOMATIC ELECTRONIC DOOR LOCK: The sterilizer is fitted automatic electronic door locking mechanism system. a)AUTOMATIC MECHANICAL DOOR LOCK: The sterilizer is equipped with automatic mechanical door locking system which prevents the user to open the door until the atmospheric pressure is achieved inside the chamber. 6.11 DUAL SAFETY VALVE: The sterilizer is fitted with spring loaded dual safety valves. 6.12 HEAT PROTECTION: The sterilizer is completely insulated with chloride face mineral glass wool to prevent any burns caused due to accidental contact to sterilizer body. 6.13 STEAM LEAKAGE PROTECTION: Heavy duty branded silicon gasket is provided for airtight seal to prevent any leakage of steam. 6.14 NABH CALIBRATED GAUGES: All our gauges including pressure, compound and digital temperature gauge are calibrated & certified by Indian most trusted NABH lab certified. 7. SEPARATE STEAM GENERATOR: The sterilizer has separate steam generator with manual water feed control valve, separate manual valve for water drain and water level indicator. 8. WATER LEVEL INDICATOR: The sterilizer is fitted with water level gauge glass to indicate the water level. 9. EXTRA PORT FOR CALIBRATION AND VALIDATION: The sterilizer is equipped with external port for the sterilizer calibration and validation. 10. FLUSH MOUNTING: The machine is equipped with SS 304 flush mounting only (Front side) Non-Sterile side. 11. PNEUMATIC VALVES The machine is fitted with Pneumatic valves for automatic processing.

Automation Grade : Automatic

Brand Name : Steri

Material : Stainless Steel

Color : Silver

Pressure : High Pressure

Usage : Industrial Use

Warranty : 1 Year

Country of Origin : India

Chamber Volume : 235 Litre

...more

YSU-605 Cylindrical Pressure Steam Sterilizer

1 Piece (MOQ)

Complete Automation at an Economy Price Introducing the STERI Horizontal Cylindrical Steam Sterilizer Gold Model, designed for customers seeking comprehensive automation at an affordable price. This model integrates advanced technology with user-friendly features, ensuring reliable and efficient sterilization. Key Features and Benefits Advanced Automatic Control System: 5 Automatic Functions: Auto Ster Auto Exhaust Auto Vacuum Dry Auto Air Dry Auto Water Feeding Programmable Logic Controller (PLC): Controlled by a pre-programmed 4.2” colored touch screen display for seamless operation. Dual Machine Operation Control: Manual Control: Operated by a multiport valve for hands-on management. Automatic Control: Managed via a 4.2” colored touch screen integrated with PLC and electric solenoid valves. Pre-Programmed Cycles: Three Cycles Included: 121°C Cycle 134°C Cycle Customizable Cycle User Customization: Allows users to adjust temperature, pressure, and vacuum pulse settings. Certifications and Standards: Certifications: ISI Mark, IS: 3829 (PART-1), ISO 9001:2015, ISO 13485:2016, WHO, GMP. Construction Standards: Built to European CE Standard. Electrical Safety: Compliant with IEC 60601-1-2016, IEC 60601-1-2, and IEC 61010-2. Premium Material Construction: Chamber and Parts: Made from high-quality SS 304 stainless steel for durability and corrosion resistance. Insulation: 50 mm thick mineral glass wool for superior heat protection. Finish: Internal mirror finish for enhanced cleanliness. Performance Specifications: Sterilizing Temperature: Adjustable from minimum requirements up to 134°C. Sterile Hold Time: Fully customizable. Chamber Pressure: Adjustable up to a maximum of 2.1 bar. Additional Features: Automatic Water Feeding System: Ensures uninterrupted operation. Optional Printing Facility: Real-time printing of cycle details, including date, time, status, temperature, and pressure. State-of-the-Art Vacuum System: Venturi Vacuum Device: Creates high vacuum pressure for dry loads. Quick Dry Ejector: For high vacuum creation (Water Ring Vacuum pump available at extra cost). Safety Features: Hydraulically Tested: Chamber, jacket, and piping tested at twice the working pressure. Automatic Pressure Control: Maintains desired pressure and prevents unsafe pressure rises. Automatic Shut Off Valve: Prevents hazardous steam and water leaks. Automatic Vacuum Breaker: Prevents jacket collapse due to vacuum. Automatic Low Water Cut Off: Protects heating elements and notifies the user of low water levels. Mechanical Door Locking System: Prevents door opening until atmospheric pressure is achieved. Dual Safety Valve: Spring-loaded for additional safety. Heat Protection: Insulated to prevent burns from accidental contact. Steam Leakage Protection: Airtight seal with heavy-duty silicon gasket. NABH Calibrated Gauges: Certified pressure, compound, and temperature gauges. Separate Steam Generator: Manual water feed control valve, drain valve, and water level indicator. Water Level Indicator: Clear gauge glass for easy monitoring. Validation Port: External port for sterilizer calibration. The STERI Horizontal Cylindrical Steam Sterilizer Gold Model delivers comprehensive automation, advanced safety features, and user-friendly operation, making it the ideal choice for efficient and reliable sterilization at an economical price.

Automation Grade : Automatic

Brand Name : Steri

Material : Stainless Steel

Shape : Cylindrical

Color : Silver

Pressure : High Pressure

Usage : Industrial Use

Warranty : 1 Year

Country of Origin : India

...more

YSU-416 Digital Ultrasonic Cleaner

1 Piece (MOQ)

Brand Name : Steri

Material : Stainless Steel

Color : Grey

Model Number : YSU-416

Packaging Type : Wooden Box

Type : Washing Equipment

Frequency : 40KHz

Warranty : 1 Year

Country of Origin : India

Temperature Controller : Digital Display With 600c Settable Controlled

...more

YSU-411 Industrial Storage Tank

1 Piece (MOQ)

Application : Industrial Use

Brand Name : Steri

Color : Grey

Capacity : 120 Litre

Type : Distillation Equipment

Country of Origin : India

Material Grade : 304

...more

YSU-409 Hot and Cold Water Sterilizer

1 piece (MOQ)