Nylon Braided Type-C USB Cable

400 Per Piece

350 Piece (MOQ)

Details: [LED Auto Disconnect Technology] First Time In India LED Auto Disconnect Technology USB Type-C Cable. LED light indicates the battery status when charging and the phone reaches full battery,With in Next 45 Minutes of completion 100% charging.the light will completely turn off. It Protects of your phone's battery from over charging. Smart inbuilt IC chip prevents over-charging of the mobile/device. The charging stops automatically after the mobile/device fully charged [Evolved Charge and Data Sync] Our cables are made with high quality, extra thick solid copper wire, which facilitates faster charge and data transmission. This cable allows you to connect your smartphone to your laptop/PC in order to charge your phone and sync / exchange data simultaneously. [Durable Material] Unrivaled Durability with Ultra Strong Nylon Braided cable and premium quality Connector for better Durability . High-quality copper wire maximizes signal quality and increases durability. [Standard 4ft (1.2 Meter)] This 4ft cable allows you to connect your Phone to your laptop/PC in order to charge your phone and sync / exchange data simultaneously from the comfort of your bed, office or sofa. [Compatibility] Samsung, HTC, Motorola, Nexus, Nokia, LG, HP, Sony, Blackberry & many more. (Not Compatible with Apple Devices & Micro USB Devices)

Double Asbestos Braided Cables

10 Per Meter

100 Meter (MOQ)

Best Deals from Braided Cable

AX 204 Braided Mobile Aux Cable

160 Per Piece

20 Piece (MOQ)

Specifications: 3.5mm Male to Male Jack Cable Length: 39 Inch/ 1 Meter. Features: Connect Smart Mobile Phones to audio output devices Attractive Red-Black Color. High Quality, Light Weight Compatibility: Compatible with Mobile Phone/ iPhone/ iPad/ iPod/MP3 Player/ MP4 Player To All Audio Systems. Warranty: 3 Months Warranty. Physical damage/scratches/water or Liquid damage will not covered under warranty. Replacement against manufacturing defects only. Additional Information: Minimum Order Quantity: 20 Piece

Silicon Fibre Glass Braided Cables

11 Per Meter

500 Meter (MOQ)

With ability to retain excellent di- electric properties when burnt, these braided cables are flame retardant and self-extinguishing. In addition to this, these cables are also resistant to fungus, UV radiations, corona discharge, acids and manganese. These cables are made with tinned copper stranded wires that are wounded twice and overlapped with polyester films braided with fiberglass. 1.1 KV Grade, Multistrand Annealed Tinned Copper (ATC) Conductor As per IS: 8130/1984 class-V, Melinex Taped, Silicon Rubber Insulated type (IE-5) As per IS: 6380/1984 & overall Fiber glass Braided with silicon varnished Rubber Flexible Cable for200°CAsperIS:9968/Pt-l/1988 Tinned Copper stranded wires twice wounded opposite and well overlapped with polyester films braided with fibreglass yarn and impregnated with high class insulating thermosetting varnish flexible up to temperature from 70"C to 200°C. Resists moisture chemicals, flames fungus radiation, corona discharged and acids ozone attack and even manages to retain excellent de electric properties when burnt Available Range: 1.5 sq.mm to 300 sq.mm (Single & Multi Core) 0.5 sq.mm to 630 sq.mm. (Single & Multicore) Application Silicon Fiber Glass Braided Cables is the best alternative to PVC, plastic and rubber insulated wire, widely used in high temperature applications. These cables have their prime applications in steel mills, foundries, glass factories, etc. Ensure overall abrasion resistance coverage, these cables are impregnated with high class insulating thermosetting varnish that can sustain wide range of temperature from 70 to 200 degree Celsius. Typical industrial applications include food processing packaging, refrigeration furnaces and lighting Fibre glass cables is used extensively as motors, transformers, lead wire and at places where conventional PVC wire is not suitable

Braided Aux Cable

12 - 15 Per piece

500 Piece (MOQ)

Verilux 4 in 1 C Type 60W Nylon Braided USB Cable

340 - 1,299 Per Piece

50 Piece (MOQ)

Copper Braided Fiberglass Cable

Get Price Quote

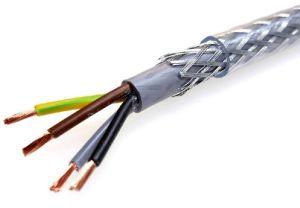

Braided Shield Cable

Get Price Quote

50 Meter (MOQ)

Classifications Cables with twisted pairs or quads with means for reducing effects of electromagnetic or electrostatic disturbances, e.g. screens Cable with a flexible connection The utility model discloses a cable, it includes a pair of heart yearn, the cladding is a pair of simultaneously the extrusion fashioned insulating layer outside the heart yearn, the cladding the shielding layer and the cladding of insulating layer the outer quilt of shielding layer, it is a pair. Double-deck aluminium foil high-speed signal line in band Similar The utility model discloses a belting double-layer aluminum foil high-speed signal wire which comprises core wires, anti-interference layers, ground wires, shielding layers and Mylar layers which are sequentially distributed from inside to outside, wherein each core wire comprises a conductor . Multi-pair data cable with configurable core filling and pair separation An improved twisted pair telecommunications cable according to the invention includes a plurality of twisted pairs of insulated conductors, and a substantially flat configurable pair separator disposed between the plurality of twisted pairs of insulated conductors along a longitudinal length of Data cable with cross-twist cabled core profile Cables including a plurality of twisted pairs of insulated conductors and a jacket surrounding the plurality of twisted pairs of insulated conductors, the jacket including a plurality of protrusions extending away from an inner circumferential surface of the jacket toward a center of the cable. Cable barrier layer with shielding segments A cable that has a cable core that includes at least one conductor that is surrounded by insulation. A barrier layer substantially surrounds the conductor's insulation. The barrier layer may include a plurality of shielding segments. Each of the shielding segments extends substantially around. Eight-type wire and production process thereof The invention discloses an eight-type wire, which comprises four groups of twisted-pair wire pairs, a linear bracket, a tinned copper wire shielding layer and a sheath; a linear bracket is arranged between the four groups of twisted-pair wire pairs; two groups of twisted-pair line pairs are . Discontinuous cable shield system and method Implementations of a discontinuous cable shield system and method include a shield having a multitude of separated shield segments dispersed along a length of a cable. The separated shield segments can serve as an incomplete, patch-worked, discontinuous, ‘granulated’ or otherwise perforated shield . 2-core shielded cable and wire harness A 2-core shielded cable and a wire harness is provided. The 2-core shielded cable is equipped with two insulated electric wires, a metal film which is provided along a length of the electric wire so as to cover the two electric wires, and a sheath which is formed around the metal film in a filled . Shielding elements for use in communication cables Cables incorporating discontinuous shielding elements are described. A cable may include at least one twisted pair of individually insulated conductors, and a shield element may be positioned adjacent to the at least one twisted pair. The shield element may include a plurality of segments. Shielded pair cable and a method for producing such a cable The present invention concerns a cable for signal transmission and a method for producing such a cable. The cable comprises one or more wire pairs extending in a longitudinal direction, each of said wire pairs including two conductors each separately surrounded by a dielectric layer. At least one. LIGHTWEIGHT BRAIDED SHIELDING FOR WIRING HARNESSES TECHNICAL FIELD This invention relates to braided shielding for a wire harness, which braided shielding is flexible and lightweight. More particularly this invention relates to a braided wire harness shield which has an open weave configuration and provides protection against electrical transients resulting from lightning strikes, and provides protection against electromagnetic interference (EMI). The braid exhibits lower (better) surface transfer impedance than conventional braided shielding for frequencies below 50 MHz. Surface transfer is an intrinsic parameter of a shield that corresponds directly to shielding effectiveness and lightning protection capability. BACKGROUND ART Wire harnesses which are used in aircraft, ships and in-ground installations are typically encased in a protective shield which is formed from multi-strand carriers which are braided onto the wire harness. The purpose of the shield is to protect the wire harness against lightning strikes and EMI. The conventional approach to providing the aforesaid protection has been to provide maximum area coverage for the wire harness with the braid, typically 85 to 95%. This approach has been taken in part because of the perceived need to provide high frequency (above 50 MHz) EMI shielding for the wire harness. The resultant braid has been conventionally formed with a relatively large angle of strand carrier application onto the wire harness, i.e., typically about 60 degrees. The weight of the shielding is a significant factor in the overall weight of the wiring components in a facility which requires such shielding. The use of the wire harness braided shielding has increased in recent years due primarily to two considerations, which are: 1) the use of electronic systems to replace mechanical devices, especially in aircraft flight controls; and 2) the use of composite materials which utilize graphite to replace metal structures in aircraft and other craft We have determined that electronic equipment can be protected against high- frequency EMI by filtering the input and output wiring using light weight components, such as pin-filter connectors, and that such filtering is sufficient to protect against frequencies greater than 50 MHz in most applications. Thus, a braided shield providing high frequency protection is unnecessary, and may only add weight and stiffness to the wiring assembly. These weight and stiffness characteristics are not desirable, especially in aircraft applications. Wire shielding is required to provide low frequency shielding for lightning protection and to preclude interference due to low frequency external electromagnetic fields. The lightning requirement stems from large transient voltages that result when lightning current flows in a resistive structure. The external field requirement arises from the fact that filter components for low frequencies are physically large and therefore impractical for applications where weight is critical, and furthermore, that such filters may interfere with proper functioning of the equipment. Therefore, wire harness shielding is needed to prevent interference from low-frequency sources. It would be desirable to provide a wire harness shielding braid which is both flexible and light-weight, and yet provides the necessary shielding protection. DISCLOSURE OF THE INVENTION This invention relates to a braided electrical shielding for an electrical wire harness, which braided shielding consists of an open braid that provides coverage for less than the entire outer surface of the wire harness, and therefore produces a lighter and more flexible braided shielding. A primary application of this invention is in lightweight lightning protection of electronic equipment installed in moderately conductive structures, such as a graphite aircraft fuselage. The invention can also be used in conjunction with non-aircraft applications which require electromagnetic protection of electronic equipment, whether installed on metallic or non-metallic structures. The percentage of wire harness coverage provided by the shielding of this invention can be as low as about 60%, and can go as high as about 70% without unduly sacrificing the desired reduction in weight and flexibility. In order to obtain the desired flexibility and weight reduction, the carrier strands of the braid are laid onto the wire harness at a relatively flat angle in the range of about eighteen degrees to about twenty four degrees, and preferably about twenty degrees, relative to the axis of the harness. The aforesaid flat braid carrier angle results in a braid which has between three and eight picks per inch, with a typical number or picks per inch being four. Present day government specs, as defined in MIL-C-27500, call for a minimum of 85% coverage of the wiring harness by the braid, and call for a braid angle in the range of eighteen to forty degrees. In practice, one cannot achieve a minimum coverage of 85% with a carrier angle in the lower end of the aforesaid range, therefore, the braid carriers are laid onto the wiring harness at angles which are at the higher end of the aforesaid range and even above the forty degree angle, up to about sixty degrees. The resultant braid will typically have about eighteen picks per inch, and is quite stiff and heavy, and does not improve low frequency performance. An unexpected result of using the open braid shielding of this invention is that shielding formed in accordance with this invention, as compared with the more dense shielding of the prior art, provides improved transfer impedance, which improvement is a function of the DC resistance of the braid. DC resistance is essentially the parallel combination of all strands in the braid. The lowest resistance is achieved by a maximum number of strands in the shielding, and equally important, minimal strand length in the braid. Minimal strand length can only be obtained by decreasing the angle of laying the braid on the harness. The ability to maintain a braid application angle that will ensure securement of the braid on the wire harness, and which also minimize strand length, so as to decrease shielding weight, is an important advantage to this invention. The necessity of achieving minimal practical coverage while meeting performance requirements in the low frequency range of DC to 50 MHz, without sacrificing adhesion of the shielding to the harness, is accomplished by utilizing a braid which has from three to eight picks per inch (a standard shield braid has eighteen picks per inch). Utilizing a braid with less than about three picks per inch results in negligible weight savings, and therefore is not seen to be particularly desirable, since a main advantage of the invention is to obtain a lessening of wire harness weight. The light weight braid of this invention does not display degraded performance at higher frequencies. The surface transfer impedance for the lightweight braid of this invention is surprisingly better than the standard heavier braid for frequencies below 50 MHz. The lightweight braid of this invention will reduce lightning-induced voltage transients by at least 25% under all conditions of use. It is therefore an object of this invention to provide an improved wire harness shielding which is lighter in weight than conventional shielding. It is another object of this invention to provide a wire harness shielding of the character described which utilizes an open braid which covers less than the entire outer surface of the wire harness. These and other objects and advantages of the invention will become more readily apparent from the following detailed description of several embodiments of the invention when taken in conjunction with the accompanying drawings in which: BRIEF DESCRIPTION OF THE DRAWINGS FIG. 1 is a plan view of a closed braid wire harness shield formed in accordance with the prior art; and FIG. 2 is a view similar to FIG. 1 but showing an open braid wire harness shield formed in accordance with this invention. DETAILED DESCRIPTION OF SPECIFIC EMBODIMENTS OF THE INVENTION Referring now to FIG. 1 , there is shown a portion of a braided shield 2 for a wire harness that is formed in accordance with the prior art. The braid employs six stranded carriers 4 that are braided onto the wire harness at an included angle d of sixty degrees. The resultant braided shield has eighteen picks per inch and covers essentially the entire outer surface of the underlying wire harness, i.e., typically about 95%. This braided wire harness is heavy, and weighs about 0.048 lb/ft when 0.0063 inch diameter carrier strands are used on a one-half inch diameter wire harness. The large angle of the braid also results in a very stiff wire harness which is difficult to manipulate and fit into tight locations, which will be found in aircraft such as helicopters and the like. The stiffness also results in problems covering wire harnesses which have different diameter portions. FIG. 2 shows a portion of a braided shield 6 which has been formed in accordance with this invention. The braid 6 employs six stranded carriers 8 which are braided onto the wire harness at an included angle β of twenty two degrees. The resultant braided shield has eight picks per inch, and includes a regular pattern of openings 10. The braided shielding 6 covers about 65% of the wire harness, and when 0.0063 inch diameter carrier strands are used, weighs about 0.025 lb/ft when braided onto a one-half inch diameter wire harness. The shielded wire harness is quite flexible and is relatively easy to manipulate into place. A weight saving of more than about 40%, as compared to the prior art braided shielding, is achieved. It will be readily appreciated that the braiding of this invention will provide substantial weight savings, and will provide the necessary lightning strike and EMI shielding for wire harnesses on which it is braided. The flexibility of the braided wire harness aids in properly placing it in tight locations which are typically found on aircraft and in other applications. Since many changes and variations of the disclosed embodiment of the invention may be made without departing from the inventive concept, it is not intended to limit the invention otherwise than as required by the appended claims.

Braided Fiberglass Cable

50 Per Meter

1000 Meter (MOQ)

copper braided cables

Get Price Quote

To keep up with the set international standards, we have incorporated the latest machines and cutting-edge technology to sternly examine the material used for production. Seeking a trusted Coppers Braided Cables supplier? Our organization is the best one and able to fulfill wholesale orders. Features : Heavy duty Fire resistant Quality standard compliant

Braided Cables

Get Price Quote

Raw materials are the inputs which are used for the production of the finished goods and thus it becomes essential for us to check the quality of the inputs before procurement. Thus, our experts do the needful. Conforming to international quality management systems, our product range is of unparalleled value. We offer a wide array of braided cables available in various lengths like 25m, 50m, 100m etc.

Braided Cables

Get Price Quote

RR KABEL Ratnaflex These cables are used as POWER cables in building and commercial infrastructure. Tool machinery, plant installation. The braided screen offers best possible protection against mechanical damage.

Braided Cable

Get Price Quote

Braided Copper Cable

400 Per Piece

1000 Piece (MOQ)

Braided Cable

Get Price Quote

GARG has utilized superior temperature stability of PTFE (-200°C to 260°C) to develop safe, efficient and long-life PTFE insulated heaters. GARG heating elements are made of various applications, Remote area heating elements: Fixed wattage and fixed length heating elements with integral heating leads under common PTFE cover with same or different colour to identify the heating zone, for heating of remote areas.

10 Sq.mm 4 Core Industrial Braided Cable

Get Price Quote

500 Meter (MOQ)

Supply of Polycore make 650/1100 Voltage Crade Circular Annealed Tinned Copper (Seven strand Class - 2 conductor) Multistrand, Type A PVC Insulated (with stand temp 70 degree), overall screened Shielded with Mylar & Back mylar tape polyester tape with ATC Drain Wire & Overall ATC Braided, PVC Type ST-1 Inner Sheath, GI Strip /Round Wire Armouring & Overall PVC Type ST-1 PVC Sheathed (outer colour Blue/Blac/kGrey ), Screened Shielded Armoured Braided cable as per BS: 5308 (Part- 2 & IS:1554 (Part-1)/1988 We will send you the Best Price shortly.

Copper Braided Fiberglass Cables

Get Price Quote

We offer Copper Braided Fiberglass Cables high on demand in the market. The Copper Braided Fiberglass Cables made accessible by us are available in various colors options including Red, Green, Blue, Black, Yellow, and Natural. They are used Alternator, Industrial Heaters, Furnaces, and Automatic changeover. Details : Conductor T.C. - 0.5sq mm to 6.0sq. mm. Bare Copper – 10.0 sq mm to 120.0sq mm Colors : Red, Green, blue, black, yellow, natural Volt Rating : 600/1100 A.C. R. M.S. Class : 'B', 'F' & 'H' (130oC, 155oC & 180oC). Applications : Pump, Alternator, industrial heaters, Furnaces, Automatic changeover etc.

Steel Braided cable 4C x 2.5 sq.mm

250 Per Meter

500 Meter (MOQ)

SS Braided extension cable

Get Price Quote

Thermocouple and RTD's Heavy duty designSS 316 / Inconel Sheath Heavy Duty, 14/32 SWG, FG/SS Braided extension cable Heavy Duty Male/ Female quick disconnect connector Widely used in Coast Guard, War Ships & Submarines

IPhone Lightning Braided Cable

499 Per Piece

The Ambrane ABCL-15 is a nylon braided iphone cable, setting a whole new benchmark of design, built and quality. Studded with best in class material and high speed charging gives you best in class user experience.1.5M of its length makes its sufficient enough and makes sure that you didn't stick to the wall sockets and comfortably enjoying while browsing your phone at distance even while it’s on charging Reversible DesignDurable Braided Nylon Material and Sturdy Design make it perfect blend of style and performance.Compatible with all Apple devices: Charge all iphones, ipads, ipods etc. Power Banks and other apple devices.Quick Charge and Faster Data TransmissionThis cable facilitates faster charging at 2.4A quick charge, faster data transmission at the speed up to 480mbps to sync your device2X More in Length than your general/regular cableTwice as long as your regular cable our 4ft. cable facilitates convenient charging from the comfort of your bed, office or sofa and makes sure that you didn't stick to the wall socketsWarranty1 Year Warranty, we took immense care and used advanced technology to build a product without worry. But just in case you have an issue, this product comes with one year manufacturer warranty Iphone Charging Cable Flexibility Highly durable Easy to connect Used for charging mobile Easy to use and carry Universal Compatible Smartphone's, Tablets, Power Bank and More.

Braided Cable

110 Per Piece

100 Meter (MOQ)

We are exporter and manufacture of copper flexible braided cables as per customer requirement and size. our copper material has 99.9% purity, comes in Electrolytic grade copper.

Polyester Braided Cable

7 Per Meter

100 Meter (MOQ)

1.5 Meter USB 2.0 Cotton Braided Extension Cable

474 Per Piece

Braided Shielded Cables

Get Price Quote

Revti Electronics Industries manufactures multi-core screened (Sheilded / braided) flexible cables used for low noise signal cables and control purposes. These cables are generally confirming to IS : 694 (1990) BS-5308 and are manufactured with flexible copper conductors, PVC insulated, Tinned copper braided / sheilded with overall PVC sheath. These cables are especially developed for defense, Telecommunication and electronic applications. Very feeble signals can be transmitted with least interference. Revti Electronics Industries manufactures multi-pair/triad instrumentation cables for use inside plants and electrical equipment where there is low frequency. These cables consist of annealed copper conductor drawn from bright electrolytic grade copper, PVC / POLYETHEYLENE / XLPE insulated, individually, or overall sheilded with BOPP & AL MYLAR. Tape, Tinned copper drain wire & overall PVC sheath. Here bunched conductors are insulated with specially formulated and developed compounds with high resistance & low capacitance values. COLOUR CODE : Two Core : Red & Black Three Core : Red, Black & Green Four Core : Red, Yellow, Blue & Green As per International practice, as also adopted by BIS, the size of conductor is decided by its resistance only. The construction of conductor is maintained within requirements of IS : 8130 – 1984 as presented by IS : 694. 1 Pair: White + Blue 2 Pair: White + Blue : White + Orange 4 Pair: White + Blue : White + Orange : White + Green : White + Brown 6 Pair: White + Blue : White + Orange : White + Green : White + Brown : White + Grey : Red + Blue

trs braided cables

Get Price Quote

We are offering a wide range of welding cable as per IS-9857-1981 standards, which are manufactured with high quality raw material to ensure optimum efficiency. At present aluminum and copper welding cables are covered under IS: 9875-1981. The earlier IS: 4341984 used to cover only VIR covering. Whereas, the present specification covers welding cables under two categories. Cable with general purpose rubber compound covering (GPR). Cable with heat resistant, oil and flame retardant compound covering (HOFR).

Braided Data Cable

Get Price Quote

1000 Piece (MOQ)

Braided Data Cable with Data Transfer or Without Data Transfer with Good configurations with 12 months Replacement warrantY

Charging And Cotton braided cable

Get Price Quote

Cotton braided usb charger cable for iphone 5 / 6 / 7 Premium Quality-Support high speed charging and sync Compatible with: for iPhone5/5S/5C/iPod Touch 5/Nano 7 -Iphone 6 and 6plus Charming and durable-golden appearance with Aluminum shell braided-nylon fiber jacket,more durable and fashion than the normal cable.Easily to use: Just connect the USB end of the cable to PC/Laptop or AC charger to get your phone charged & sync Data Note: This is not original apple cable. 1.5m Long

steel braided cables

Get Price Quote

Copper conductor, Single Core / Multi Core / Multi Pair PVC / XLPE / FR-XLPF, insulated, Steel wire braided(Armouring), PVC / PVC-ST2 / FR / FRLS / LSOH sheathed cables to provide flexibility and added mechanical protection.

EVM Nylon Braided Cable

299 Per Piece

Silicon Fibre Glass Braided Cables

Get Price Quote

With ability to retain excellent di- electric properties when burnt, these braided cables are flame retardant and self-extinguishing. In addition to this, these cables are also resistant to fungus, UV radiations, corona discharge, acids and manganese. These cables are made with tinned copper stranded wires that are wounded twice and overlapped with polyester films braided with fiberglass. Description:- 1.1 KV Grade, Multistrand Annealed Tinned Copper (ATC) Conductor As per IS: 8130/1984 class-V, Melinex Taped, Silicon Rubber Insulated type (IE-5) As per IS: 6380/1984 & overall Fiber glass Braided with silicon varnished Rubber Flexible Cable for200°CAsperIS:9968/Pt-l/1988 Tinned Copper stranded wires twice wounded opposite and well overlapped with polyester films braided with fibreglass yarn and impregnated with high class insulating thermosetting varnish flexible up to temperature from 70"C to 200°C. Resists moisture chemicals, flames fungus radiation, corona discharged and acids ozone attack and even manages to retain excellent de electric properties when burnt Application:- Typical industrial applications include food processing packaging, refrigeration furnaces and lighting Fibre glass cables is used extensively as motors, transformers, lead wire and at places where conventional PVC wire is not suitable. Available Range:- 1.5 sq.mm to 300 sq.mm (Single & Multi Core) 0.5 sq.mm to 630 sq.mm. (Single & Multicore