Roll To Roll Paper Printing Machine

Get Price Quote

Steel Bar Thread Rolling Machine

110,000 - 155,000 Per Piece

All roller dia built by die steel with hi tempreature heat tritment. Inclusive all size of scale for sze measuring

Best Deals from Rolling Machine

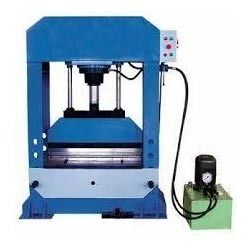

3 Roll Hydraulic Plate Bending Machine

300,000 - 1,500,000 Per Set

1 Set (MOQ)

Scrap Bailing Machine

SLITING MACHINE ROLLER

Get Price Quote

Pipe Rolling Machines

Get Price Quote

Starting Price: Rs 70,000 / Piece Being a customer oriented firm, we are engaged in offering a wide range of Pipe Rolling Machines. These machines are manufactured using best grade raw-material and latest technology in synchronization with industry norms. In order to make sure quality, the entire range is meticulously tested on different parameters by quality examiners. Keeping in mind the varied needs of our clients, we offer the entire range in different specifications and at affordable price. Features: Rugged construction Anti corrosive body Require less maintenance

Pyramid Plate Rolling Machine

Get Price Quote

Longitudal Grooves on Bottom rolls for correct Feeding of Plates. Build in Lubricated Storage. Circumferencial and Axial Grooves on Gun Metal Bearing for even Lubrication. Gun Metal Bush Bearings. Dropend opening system for easy removal of rolled shells. Minimised feeding height for easy operation. Well balanced design. Controlled roll speed for accurate curvature performance. Indicators provided for correct even top roll presure. Mechanical device Mechanism for easy sliding of non drive side top roll housing. Motor of reputed make. Worm Reduction Gear-Box of reputed make. Reverse Forward starter with overload thermal relay of reputed make like Siemens/L & T/Cutler Hammer/HKS. One piece fabricated heavy duty base frame. UNIQUE SPECIAL DESIGNED OPTIONAL : Extended rolls (To be ordered alongwith machine) Dies for rolling of angles, channels, pipes, flats, I-beam etc Attachment for conical rolling. Extra heavy base frame (for site work) Direct coupled gear box with electric motor and electro magnetic brake. Semi automatic centralised lubrication systrm. Feeding plateform. Interchangeable extra top roll to roll shells of smaller diameter Spilproof re-usable lubrication system. Manual or pneumatic or mechanical shell ejecting device. Remote floating control. Shell support device. Gun metal nuts for smoother manual rotation. 50% thick plates than the rated capacity can be bent on the machine by hammering action as shown while the thicker plates have to be prebentoutside the machine. Insert the plate between top roll and bottom roll by adjusting the top roll manually. Apply pressure on the plate by lowering the top roll, then start the main motor in forward direction till one end of plate comes over the first bottom roll. Then stop the main motor and reverse its direction so that other end ofthe plate will come on second bottom roll. Repeat the same procedure by applying the pressure from top roll till you get a perfect shell as shown on figure. For removal of rolled shell reduce the pressure of the top roll, make the shell free between top and bottom rolls, remove tilting end bearing of top roll manually and take out the shell, (Please note that top roll is balancd by means of balancing screw.) Replace that bearing and the machine is ready for next operation.

paper rolling machine

Get Price Quote

This hi-speed toilet paper toilet roll making machine is available in 810mm, 1020mm & 1650 mm working widths. It is slitting machine with perforation. Slitting blades could be adjusted to make Kitchen Rolls & Industrial rolls. Electronic counter is provided which controls the No. of sheets to be wounded over a given roll in this toilet roll making machine. Special Features : Consistent Functioning Energy Efficient Operation Longer Functional Life Perforation Unit Slitting Unit Embossing Unit (Optional)

Shelter Rolling Machine

Get Price Quote

Roll Forming (Shelter Rolling Machine).

plate rolling

Get Price Quote

SS Plate Rolling Machine

Get Price Quote

SS Plate Rolling Machine

Roll To Roll UV printing Machine

Get Price Quote

Roll To Roll UV printing Machine, automatic glass cutting machine, Cnc Routers

Corrugated Roof Panel Roll Forming Machine

Get Price Quote

Corrugated Roof Panel Roll Forming Machine

Toilet Roll Making Machine

Get Price Quote

Toilet Roll Making Machine