White Clay Lumps

800 - 1,000 Per Ton

25 Ton (MOQ)

White clay is sedimentary clay having properties of no shrinkage at 1120°C temperature and giving good-fired strength to the tiles fired at low temperature below 1150°C. Because of no shrinkage or expansion, size will not shrink more in firing. Best suited for wall tiles for both single firing and double fast firing. This clay helps in fast degasification in ceramic tiles because of lower loss on ignition (below 4%) compared to any clays.

Color : White

Form : Lumps

Application : Industrial

Country of Origin : India

...more

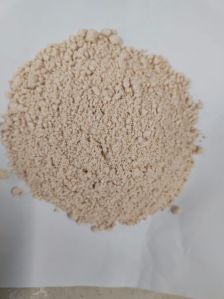

Washed Soda Feldspar Powder

3,500 - 5,000 Per Ton

25 Ton (MOQ)

Feldspars are sodium, potassium and calcium aluminosilicates that constitute 60% of the Earth’s crust.Feldspars of importance to ceramics are aluminosilicates of sodium , potassium and calcium. They are used as fluxes to form a glossy phase in bodies , thus promoting vitrification and translucency . they are also serve as a source of alkalies and alumina in glazes. The pure spars are albite (NaAlSi3O8), orthoclase or microcline(KAlSi3O8) and anorthite(CaAlSi3O8). The soda feldspars are used in glasses and glazes, the high potash feldspars in whiteware bodies. Potash feldspar enable the broadest firing range and the best stability of the body aginst deformation during firing. Sodium feldspar exhibits a lower viscosity than potash feldspar when melted at a given temperature.Feldspars are the main vitrifying or fluxing agents used during the firing process of ceramic bodies. Fluxes melt at an early stage in the firing process, forming a glossy matrix that bonds the other components of the system together, ensuring the durability of firing bodies.We offer washed soda feldspar with good whiteness. Washed soda feldspar best suited for double charge top bodies and glazes where more whiteness and melting required.

Country of Origin : India

Color : White

...more

Washed Potash Feldspar Powder

3,500 - 5,000 Per Ton

25 Ton (MOQ)

Feldspars are sodium, potassium and calcium aluminosilicates that constitute 60% of the Earth’s crust. Feldspars of importance to ceramics are aluminosilicates of sodium, potassium and calcium. They are used as fluxes to form a glossy phase in bodies, thus promoting vitrification and translucency. They are also serve as a source of alkalies and alumina in glazes. The pure spars are albite (NaAlSi3O8), orthoclase or microcline (KAlSi3O8) and anorthite(CaAlSi3O8). The soda feldspars are used in glasses and glazes, the high potash feldspars in white ware bodies. Potash feldspar enable the broadest firing range and the best stability of the body against deformation during firing. Sodium feldspar exhibits a lower viscosity than potash feldspar when melted at a given temperature. Feldspars are the main vitrifying or fluxing agents used during the firing process of ceramic bodies. Fluxes melt at an early stage in the firing process, forming a glossy matrix that bonds the other components of the system together, ensuring the durability of firing bodies.We offer washed potash feldspar with good whiteness. Washed potash feldspar best suited for double charge top bodies and glazes where more whiteness and melting required.

Color : Brown

Application : Industrial

Country of Origin : India

...more

Talc Powder

2,000 - 4,000 Per Ton

25 Ton (MOQ)

Talc powder is a naturally occurring mineral that is composed of hydrated magnesium silicate. It is a soft and white powdery substance that has been used for various purposes. Talc is widely used in industries such as cosmetics, pharmaceuticals, ceramics, paint, paper, and rubber.Talc powder is used in the ceramics industry as a filler and a flux. It is added to clay to improve its strength and to make it easier to mold. Talc is also used as a flux in ceramic glazes and bodies to lower the firing temperature and to improve the opacity and whiteness of the glaze. Talc is valued in the ceramics industry for its high melting point, chemical inertness, and ability to improve the properties of ceramic products. Talc powder is used in paint as a filler and a pigment extender. It is added to paint to improve its opacity and to reduce its cost. Talc is also used as a flatting agent in some paints to create a matte finish. Talc powder is preferred in the paint industry for its chemical stability, low oil absorption, and ability to improve the hiding power and rheology of paint.Talc powder is used in paper as a filler and a coating. It is added to paper to improve its opacity and brightness and to make it easier to print on. Talc is also used as a coating on some paper products such as glossy magazines to improve their surface properties. Talc is a preferred ingredient in the paper industry due to its whiteness, low abrasiveness, and ability to enhance the printing properties of paper.Talc powder is used in rubber as a filler and a reinforcing agent. It is added to rubber to improve its strength, stiffness, and resistance to heat and chemicals. Talc is also used as a release agent in the rubber manufacturing process to prevent the rubber from sticking to the molds. Talc is valued in the rubber industry for its chemical inertness, low abrasiveness, and ability to improve the mechanical and processing properties of rubber products.We are supplying good whiteness talc to ceramic tiles industry.

Color : White

Shelf Life : 1year

Country of Origin : India

...more

Quartz Powder

3,000 - 5,000 Per Ton

25 Ton (MOQ)

Quartz is a mineral composed of silicon and oxygen, with a chemical composition of SiO2. It is the most abundant mineral in Earth's crust and is resistant to both chemical and physical weathering. When rocks weather away, the residual material usually contains quartz. This is why the sand at most of the world's beaches is quartz.It is abundant in igneous, metamorphic, and sedimentary rocks.Quartz is one of the most useful natural materials. Its usefulness can be linked to its physical and chemical properties. It has a hardness of seven on the Mohs Scale which makes it very durable. It is chemically inert in contact with most substances. It has electrical properties and heat resistance that make it valuable in electronic products. High-purity quartz sandstone suitable for the manufacture of high-quality glass. "Glass sand" is a sandstone that is composed almost entirely of quartz grains. Much of it has been used for container glass, but some of it has been selected for use in making lenses for the largest telescopes. The high hardness of quartz, seven on the Mohs Scale, makes it harder than most other natural substances. As such it is an excellent abrasive material. Quartz sands and finely ground silica sand are used for sand blasting, scouring cleansers, grinding media, and grit for sanding and sawing. Quartz is very resistant to both chemicals and heat. It is therefore often used as a foundry sand. With a melting temperature higher than most metals, it can be used for the molds and cores of common foundry work. Refractory bricks are often made of quartz sand because of its high heat resistance. Quartz sand is also used as a flux in the smelting of metals. Quartz sand is used as a filler in the manufacture of rubber, paint, and putty. Quartz powder is one of the most important ingredients in glass manufacturing. The high purity and small size of its particles enable the product to be used to produce first-quality glass in bottles, containers, optical glass, etc. Quartz powder is used in the ceramics industry to improve the properties of ceramic products. It improves strength, decreases shrinkage during firing, and increases thermal stability.Quartz powder functions as both a filler and a thickening agent in the paint and coatings industry. It improves viscosity and texture, enhancing paint durability in its application.Our quartz powder having low iron and good whiteness. No shrinkage at 1230 degree centigrade temperature. Suitable for glazes, engobes and body preparation of tiles and sanitaryware.

Country of Origin : India

State : Powder

Application : Industrial

Color : White

...more

Quartz Lumps

25 Ton (MOQ)

Material : Quartz Stone

Shape : Lumps

Color : White

Form : Solid

Grade : Industrial Grade

Packaging Type : Plastic Bags

Country of Origin : India

...more

Potash Feldspar Chips

1,500 - 2,500 Per Ton

25 Ton (MOQ)

Feldspars are sodium, potassium and calcium aluminosilicates that constitute 60% of the Earth’s crust.Feldspars of importance to ceramics are aluminosilicates of sodium , potassium and calcium. They are used as fluxes to form a glossy phase in bodies, thus promoting vitrification and translucency. They are also serve as a source of alkalies and alumina in glazes. The pure spars are albite (NaAlSi3O8), orthoclase or microcline(KAlSi3O8) and anorthite(CaAlSi3O8). The soda feldspars are used in glasses and glazes, the high potash feldspars in whiteware bodies. Potash feldspar enable the broadest firing range and the best stability of the body against deformation during firing. Sodium feldspar exhibits a lower viscosity than potash feldspar when melted at a given temperature.Feldspars are the main vitrifying or fluxing agents used during the firing process of ceramic bodies. Fluxes melt at an early stage in the firing process, forming a glossy matrix that bonds the other components of the system together, ensuring the durability of firing bodies.We offer Potash chips having particle size in between 0 to 5 mm. having low iron content and good whiteness.

Color : Light -brown

Application : Construction

State : Chips

Country of Origin : India

...more

Kaolin Lumps

5,000 - 8,000 Per Ton

25 Ton (MOQ)

Kaolin is soft white clay that is an essential ingredient in the manufacture of sanitary and porcelain and is widely used in the making of paper, rubber, paint, and many other products. Kaolin is named after the hill in China (Kao-ling) from which it was mined for centuries.Kaolin is used extensively in the ceramic industry, where its high fusion temperature and white burning characteristics makes it particularly suitable for the manufacture of whiteware , porcelain, and refractories. The absence of any iron, alkalies, or alkaline earths in the molecular structure of kaolinite confers upon it these desirable ceramic properties. In the manufacture of whiteware the kaolin is usually mixed with approximately equal amounts of silica and feldspar and a somewhat smaller amount of a plastic light-burning clay known as ball clay. These components are necessary to obtain the proper properties of plasticity, shrinkage, vitrification, etc., for forming and firing the ware. Kaolin is generally used alone in the manufacture of refractories.Kaolins are used for filling rubber to improve its mechanical strength and resistance to abrasion. For this purpose, the clay used must be extremely pure kaolinite and exceedingly fine grained. Kaolin is also used as an extender and flattening agent in paints. It is frequently used in adhesives for paper to control the penetration into the paper. Kaolin is an important ingredient in ink, organic plastics, some cosmetics, and many other products where its very fine particle size, whiteness, chemical inertness, and absorption properties give it particular value.

Country of Origin : India

...more

Glaze Grade Ball Clay

5,000 - 8,000 Per Ton

25 Ton (MOQ)

Ball clay and china clay differ only in the degree of plasticity. China clay is less plastic than ball clay. Ball clay is a highly plastic variety of kaolin having high binding power, tensile strength and shrinkage. Ball clays are fine grained, highly plastic sedimentary clays, which fire to a light cream or near white colour. ball clays exhibit highly variable compositions and consist of a mixture, primarily of kaolinite, mica and quartz, with each contributing different properties to the clay. Ball clays are mainly used in the manufacture of ceramic white ware and are valued for their key properties of plasticity, unfired strength and their light-fired colour.Ball clays would be ideal ceramic materials. However, in practical terms, they are employed to achieve the desired plasticity but minimized to reduce the detrimental effect on fired whiteness and drying properties. Ball clay is a binding agent and helps to enhance the plasticity, workability, and strength of a pre-fired ceramic body. Some are highly effective for their fluid and casting properties, particularly in the manufacture of sanitaryware. Ball clays are used in ceramic bodies because of their plastic nature combined with high firing temperature. Ball clays have very high dry and green strength and slow drying.We have ball clay having good plasticity and flow properties with white firing colour. Best suited for Engobe preparations and sanitary ware.

Color : Grey

Form : Lumps

Application : Industrial

Country of Origin : India

...more

Dolomite Lime

25 Ton (MOQ)

Form : Lumps

Grade : Industrial Grade

Color : Snow-white

Application : Cement Industry

Packaging Type : Drums

Country of Origin : India

...more

China Clay Lumps

800 - 2,000 Per Ton

25 Ton (MOQ)

China Clay is also known as kaolin & white clay. Primary clay formed by natural kaolinisation process. It is formed by the decomposition of some part of feldspar mineral. White in colour, Used in the ceramic slip casting process, pressing processes and forming process as a body former and filler. Chemical formula of china clay is Al2O3 2SiO2 2H2OProcessing of China Clay:Processing of china clay difference from place to place but the essential step are the same. i)Excavating china clay. ii) Sieving process. iii) Settling process. iv) Filter press process. v) Drying process. vi) Packing and TransportingProperties of China Clay:China clay is Primary clay and generally found in white colour. Casting Rate: High casting rate in slip casting compared to ball clay. Particle size: Large particles when compared to Ball clay. Green MOR: Modulus of rupture is low compared to ball clay. Plasticity: Low plasticity compared to ball clay. Refractoriness: High Refractoriness. Uses of China Clay:China clay used in all Kind of ceramic product production and other products for its properties. Following are the primary uses of the china clay, Used In Sanitaryware industry Used in the tiles Production industry. Used in Refractory production. Used in the Paper industry as a filler. Used in Rubber industry as a raw material. Used in textiles industries. Used in the Dinnerware production process as a raw material.

Country of Origin : India

Style : Dried

Application : Industrial

Color : Grey

Form : Lumps

...more

Calcite Lumps

25 Ton (MOQ)

Color : White

Form : Lumps

Application : Constructional

Type : Calcite Lumps

Country of Origin : India

Pacakging : Gunny Bag

...more

Bentonite Lumps

10,000 - 14,000 Per Ton

25 Ton (MOQ)

Bentonite is an absorbent swelling clay consisting mostly of montmorillonite which can either be Na-montmorillonite or Ca-montmorillonite. Na-montmorillonite has a considerably greater swelling capacity than Ca-montmorillonite.Bentonite usually forms from the weathering of volcanic ash in seawater, or by hydrothermal circulation through the porosity of volcanic ash beds, which converts the volcanic glass present in the ash into clay minerals.Plasticity is the property of bentonite clay that allows it to be manipulated and retain its shape without cracking after the shaping force has been removed; clays with low plasticity are known as short or non-plastic. A small amount of bentonite added to clay can increase its plasticity, and hence ease forming of articles by some shaping techniques.Ceramic glazes often contain bentonite. The bentonite is added to slow or prevent the settling of the glazes. It can also improve the consistency of application of glazes on porous biscuit-fired ware. Once a certain amount of glaze water has been absorbed by the biscuit the bentonite effectively clogs the pores and resists the absorption of further water resulting in a more evenly thick coat.

Grade : Technical

Color : White

Whiteness : 50-99%

Form : Lumps

Country of Origin : India

...more

Ball Clay Lumps

800 - 2,000 Per Ton

25 Ton (MOQ)

Ball clay and china clay differ only in the degree of plasticity. China clay is less plastic than ball clay. Ball clay is a highly plastic variety of kaolin having high binding power, tensile strength and shrinkage. Ball clays are fine grained, highly plastic sedimentary clays, which fire to a light cream or near white colour. ball clays exhibit highly variable compositions and consist of a mixture, primarily of kaolinite, mica and quartz, with each contributing different properties to the clay. Ball clays are mainly used in the manufacture of ceramic white ware and are valued for their key properties of plasticity, unfired strength and their light fired colour.Ball clays would be ideal ceramic materials. However, in practical terms, they are employed to achieve the desired plasticity but minimized to reduce the detrimental effect on fired whiteness and drying properties. Ball clay is a binding agent and helps to enhance the plasticity, workability, and strength of a pre-fired ceramic body. Some are highly effective for their fluid and casting properties, particularly in the manufacture of sanitaryware. Ball clays are used in ceramic bodies because of their plastic nature combined with high firing temperature. Ball clays have very high dry and green strength and slow drying.We have large variety of ball clay having different plasticity indexes, firing colour, dry strength and fired strength.

Country of Origin : India

Application : Industrial

Form : Lumps

Color : Grey

...moreBe first to Rate

Rate ThisOpening Hours