Yarn Filter Cartridge

Machines handle polypropylene viscose or cotton yarns used in wound cartridges. Individually based on wound cartridge lengths and diameter. Special modules can be supplied for fine stainless steel wire winding. Machine designed and built for ease of operation and minimal maintenance. Filter diameter control device Aluminum extruded section base frame and powder coated paint finish Machine speed variable. Safety guards.

...more

wire winding machine

A2Z Coil Filter making machine is designed to wind the paper filter cartridge. Equipment is supplied with Water based gluing system or hot melt system to paste the edges and ends of media. This system includes corrugation of media across half the widths, folding the media from middle of the width, filter diameter detection and automatic end cutting.

...more

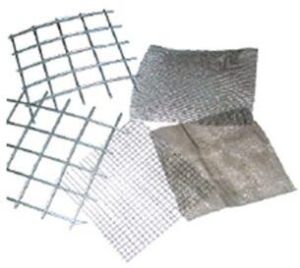

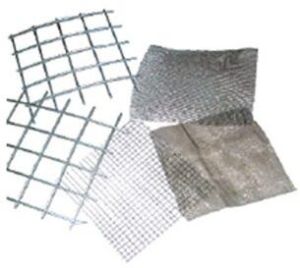

welded mesh machines

Weld mesh can be supplied as per customer's design and requirements either zinc plated or powder coated in roll form or cut to size. Stainless steel or GI Wire meshes can be supplied in roll form.

...more

weld mesh machines

Weld mesh can be supplied as per customer's design and requirements either zinc plated or powder coated in roll form or cut to size. Stainless steel or GI Wire meshes can be supplied in roll form.

...more

tube rolling machines

A2Z Tube Rolling machines have been designed to produce tubes of expanded and perforated metals upto 1000mm width and 0.3mm to 1mm sheet thickness and can produce tubes of 60mm to 600mm diameter and are custom made for working widths and the machine permits easy adjustments for different tube diameters.

...more

thread winding machine

Machines handle polypropylene viscose orcotton yarns used in wound cartridges. Individually based on wound cartridge lengths and diameter. Special modules can be supplied for fine stainless steel wire winding. Machine designed and built for ease of operation and minimal maintenance.

...more

Spiral Tubes

Available in various sizes and dimensions to suit customer's needs and specifications and only orders for large volumes are accepted owing to specific manufacturing process.

...more

sheet decoiling machine

State of the art Solidworks® 3D design software for design & simulation of equipment. Components and parts from leading global suppliers to achieve a distinctive durable and globally serviceable product. Easy availability of components and spares for trouble free maintenance.

...more

Rotary Pleating Machine

Rotary Pleating Machines are custom built for range of widths, capacity and pleat depths and designed for high speed production. Machines are supplied with pictorial user-friendly manuals. Manufactured usin internationally recognized, serviceable and replaceable parts for trouble free maintenance. Distinctive & Durable. Designed on State-of-the-art Design software allowing tailor made solution for optimal performance. Experienced Installation teams & Specialised Training available.

...more

Pulp Disintegrator

A pulp sample is said to be disintegrated when it has been subjected to mechanical treatment in water so that interlaced fibres, which were free in the pulp stock, are again separated from one another without appreciably changing their structural propertie

...more

plating machine

Versatile Pleating for a variety of media like Filter Papers, Glass Fiber, Synthetic Medias, Stainless Steel Wire Mesh and a combination of fabric and wire mesh (also heavy Stainless Meshes) or any other pleatable medias Machines are supplied with pictorial user-friendly manuals Manufactured using internationally recognised, serviceable and replaceable parts for trouble free maintenance. Durable and aesthetically designed Designed on state-of-the-art design software allowing tailor made solutions for optimal performance Qualified teams for installation & specialised training available

...more

perforation press

A2Z perforation Presses are offered for both Heavy Duty and Light Duty applications. Perforation Press has been designed to perforation of Paper Board, wrapper sheets or sheet metals. Perforations dies are engineered to suit materials in reels or coils and in any desired pattern. Pneumatic clutch Centralized lubrication systemPerforated sheets are generally used as outer wrapper filter cartridge, outer and inner tube for filter cartridge.

...more

perforated tube

Decoiler stand for raw material coil Automatic length measuring & cutting device. Automatic centralized lubrication system. One mandrel set for one diameter of tube is enclosed in the machine price. Additional mandrel set can be supplied at extra cost. Tube length changes on the fly.

...more

Knife Pleating Machine

Versatile Pleating for a variety of media like Filter Papers, Glass Fiber, Synthetic Medias, Stainless Steel Wire Mesh, and a combination of fabric and wire mesh (also heavy Stainless Meshes) or any other pleatable medias, Machines are supplied with pictorial user-friendly manuals, Manufactured using internationally recognised, serviceable and replaceable parts for trouble free maintenance. Durable and aesthetically designed, Designed on state-of-the-art design software allowing tailor made solutions for optimal performance, Qualified teams for installation & specialised training available.

...more

Hot Melt Applicator

This operation enables the pleated cartridge media to remain in place during usage and the process ensures uniform pleat distribution. A2Z's Hot melt applicator has been designed to apply the hot melt as spiral bead on inner diameter and outer diameter of filter. Number of hotmelt bead spirals can be adjusted as per requirement. This equipment can be used for cylindrical, conical & square end cap filters.

...more

GI Welded Mesh

Weld mesh can be supplied as per customer's design and requirements either zinc plated or powder coated in roll form or cut to size. Stainless steel or GI Wire meshes can be supplied in roll form.

...more

gi mesh

Weld mesh can be supplied as per customer's design and requirements either zinc plated or powder coated in roll form or cut to size. Stainless steel or GI Wire meshes can be supplied in roll form.

...more

freeness tester

A2z's Beating and Freeness Tester Schopper Riegler Type, measure the drainage of a pulp suspension, as determined by the schopper riegler method and expressed as the SR number. The most reliable results are obtained within the SR number range of 10-90.

...more

Filter Manufacturing Equipment

A2Z Filtration Specialities Private Limited is a team of young, dynamic, experienced professionals, These include Engineers and Specialists in the field of Design, Development, Manufacturing and Installation at our Design centre and two Production facilities.

...more

filter making machine

Working Speed : up to 120pcsmin (depending on diameter and length of tube), Material width : 45mm, Material thickness (mm) : 0.25 to 0.4mm, Material Grade : Mild Steel – extra deep drawn grade. Tube length : 25 to 500 mm (length can be increased by adding additional Tube support),Electrical supply : As per customer requirement. Designed to produce perforated and louvred spiral tube used for filters, Machine has automatic length measuring & cutting devices. Equipped with decoiler.

...more

Filter Cage Welding Machine

The machine conforms to latest international standards. Selection of correct weld time using solid state electronic timer ranging from 5-99-199 cycles. Rocker Arm type spot welders are designed and developed to meet the needs of a vast number of metal fabrication shops. Besides spot welding the machine can also be used for electro brazing, cross wire welding and resistance heating.

...more

Decoiler

State of the art Solidworks® 3D design software for design & simulation of equipment. Components and parts from leading global suppliers to achieve a distinctive durable and globally serviceable product. Easy availability of components and spares for trouble free maintenance.

...more

Corrugating Machine

A2Z range of corrugating machines have been designed to fit inline with allied equipment for filter paper processing. Filter manufacturers will find a2z corrugating machines as versatile and helpful in optimizing media performance.

...more

Cabin Air Filter

To address the needs of the rapid growth in Cabin Air Filtration, A2Z has introduced an automated line that is flexible, fit to purpose and cost effective for filter manufacturers. A2Z Cabin Air Filter Line consisting of Blade Pleater, Inline Slitter, Automatic Cross Cutter and side Gluing system with Hotmelt Applicator. PLC Controlled Automatic Pleat depth adjusment Automatic lubrication controller. Memory of pre set values for different functions. Status indicator for different functions.

...moreBe first to Rate

Rate This