Vibrating Screens

We are offering vibrating screens. vibrating screen is a kind of sieving equipment of international advanced level, developed by our company on the basis of carrying on the advantages of traditional screens and absorbing the outstanding technology from abroad it is widely used for grading and screening materials like minerals, stones, limestone, coal, building materials and other. the vibrating equipment is used to separate materials. It is composed of main frame of screen, motor, eccentric shaft, springs and deck plates. Company supplies suitable type according to customers’ demands. These are simple, reliable and have high screening capacity and high durability. chm manufactured range of industrial vibrating screens is used as standard practice where large capacity and high efficiency of screening are desired. The vibrating screens which we manufacture are used for standalone or multiple installations. Made according to the diverse demands, a wide range of sizes of these screens are manufactured. In these vibratory screens each unit is compatible with all screening systems and can be integrated into existing and current processing plants.

...more

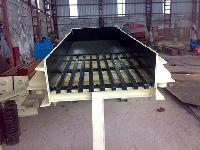

Vibrating Grizzly Feeders

160,000 - 1,800,000 Per Piece

1 Piece(s) (MOQ)

We are offering vibrating grizzly feeders. vibrating grizzly feeders are used in extraction and conveyance of materials of very large size from storage bins and hoppers, and are conveyed to downstream crushers, while screening the materials. our vibrating feeders are mainly used for continuous and evenly feeding coarse to crusher, screening fine aggregate, and thus enhances crusher capacity. When operated, the vibrating feeder can send massive and granular materials to the crusher evenly, regularly and continuously. In the sand making production line, its even and continuous feeding crusher helps avoid feeding-hole blocking. chm feeders are available in all sizes for capacity upto 800 tph. the features are : smooth in vibration have reliable operation. long service life. low noise. low power consumption. easy to adjust. simple structure. easy to install. light weight. small volume. simple maintenance.

Type : Feeders

Condition : New

Frequency : 50Hz

Driven Type : Electric

Warranty : 1yrs

Country of Origin : India

...more

Vibrating Grizzly Feeder

They are used in extraction and conveyance of materials of very large size from storage bins and hoppers, and are conveyed to downstream crushers, while screening the materials. Vibrating Grizzly feeder is used in feeding calcareous, calcium containing material with a size up to 1,000mm at 600m3 per hour also it is used for the separation of fines from primary feed or secondary feed to the crushing plant and is meant for heavy duty applications. CHM projects manufacturers, exports and supplies fine quality of Vibrating Grizzly Feeder.

...more

Vertical Shaft Impact Crusher

We are offering vertical shaft impact crusher. vertical shaft impact crusher ( vsi ) is more suitable for crushing mid-hardness materials and high-hardness materials and its product is cubic, and the density of piling up is high and the iron pollution is low. Vertical shaft impact crusher ( vsi ) is widely used in metal and nonmetal mine, concrete, fireproof material, abrasive filler, frit, construction aggregate, sand, metallurgy and so on. it is applied widely for the powder process of mineral product including mental and non-metay ore, fireproof material, bauxite, diamond dust, glass raw materials, archtiectural materials, artificial sand and all kinds of metal ore materials, especially which has more advantages than any other machines in processing the more and most hard materials. features of vertical shaft impact crusher: 1. Standard replacement parts 2. Heavy duty design 3. High productivity 4. Minimum maintenance 5. Safe and user-friendly 6. Cubically shaped product 7. Cost effective 8. Excellent performance and high final fineness 9. Smooth and quiet operation 10. Long service life

...more

Stone Hoppers

We are offering stone hoppers. we offer a complete range of feed hoppers which are specially designed to cope with a variety of capacity requirements. These heavy duty units can be used for the feeding of stone and aggregate type materials such as: � stones � coal � limestone � slag � dolomite � clinker we currently offer a range of capacities within the range to suit your specific application. All our feed hoppers include an upper liner to ensure the efficient transition of material from the feed hopper to the next stage of material processing.

...more

Stone Crushing Plants

We design, manufacture, supply and commission complete crushing plants for various minerals such as stone, iron ore limestone, coal, gypsum, dolomite etc. we carry out the work on turn-key basis and our product range includes dump hoppers, vibrating grizzly feeders, jaw crushers, cone crushers, impact crushers, vibrating screens, vibro feeders, belt conveyors, surge bins, electrical control panels etc. we can supply plants upto 800 tph capacity.

...more

Jaw Crushers

We offer jaw crushers with complete range of single toggle and double toggle jaw crushers which are specially designed for consistent performance for all type of heavy-duty applications in all types of rocks, ores & mineral crushing. These crushers are robust, heavy duty and need little maintenance. The swing jaw or the pitman is mounted on a shaft with four heavy duty self aligning spherical roller bearings with a provision to adjust the gap as per the gradation requirements. accurately balanced steel structure allows for easy and economical installation. Crushers are based on a revolutionary stress relieved, mig welded frame construction giving highest possible fatigue strength, excellent reliability and numerous mounting possibilities. All its wear parts are highly durable of special high quality steel components. To ensure smooth crushing action, two precise counter balanced flywheels are provided. Simple locking arrangements are provided for easy replacement or reversing the jaw liners.

...more

Crusher Spare Parts

We are offering crusher spare parts. we provide of an eminent range of spare parts for crushers and other equipments that are widely demanded in various small and large scale stone & mineral industries. We offer spare parts for: jaw crusher vibrating screens cone crushers impact crushers vibrating grizzly feeder rotopactor machine sand classifier/ screw conveyor coal crusher belt conveyors please call for any requirement.

...more

Single Toggle Jaw Crusher

Developed for crushing of minerals and rubbles includes grease lubricated roller bearings, two flywheels, grooved for V-belt drive and the other acts as a weight, hydraulic jaw adjustment via operated pump, with overload protection system and fitted with reversible manganese jaw plates and side cheek liners. Effective crusher’s motion maximizes production, reduces usage for secondary crushing. High output rates, lower operational costs are its major applications.

...more

Screening plant

Sand Classifier

We offer Sand Classifiers which are used for the separation of crushed sand (stone particles below 3 mm.) from natural mud or silt, is based on the principle that the former is heavier than water but the latter is not. Silt mixed crushed sand if used for making concrete yields low strength and hence this machine is particularly useful for obtaining crushed sand for use in high strength concrete. Our Sand Classifier consists of an inclined screw conveyor with a water jacket. Water is retained till a particular level. The mixture of silt and sand is fed at the feed (lower) end of the inclined screw conveyor. The silt particles being lighter than water do not settle down and are drained away with water. The crushed sand being heavier than water settles on the bottom part of the trough of the screw conveyor and is conveyed at the discharge end.

...more

Rotopactor Machine

We are offering rotopactor machine. we offer rotopactor which is basically a rotary crusher used in the secondary or tertiary stage of a stone crushing plant. Its sturdy design consists of an impeller (rotor) rotating at 1000-1200 r.p.m. Inside a steel fabricated body lined with high grade austenitic manganese steel breaker liners. it can handle large quantity material and selectively reduce their particles into desired sizes. This process in executed very quickly and efficiently. The finished products obtained from this process are technically & comfortably acceptable to any authority, which include nhai, most or dam construction. the stone to be crushed is fed directly into the centre of the rotor, the high rotating speed of which throws the material outwards towards the breaker liners and other flying crushed particles for further impact crushing. The result of the process is production of absolutely cubically crushed stone, which finds great use in the construction sector. the rotor is completely dis-assemblable and hence all its components - back plate, eight rollers and ring (all of manganese steel casting) can be individually replaced to avail optimum useful life. The direction of rotation of the rotor can be reversed to prolong the useful life of the same as well as the breaker liners, thereby reducing the cost of crushing. none of the components requires frequent adjustment like in a jaw crusher, roll crusher or cone crusher and hence the down time is very less.

...more

Road Marking Machine

Thermoplastic road marking machine is used as an edge marking on roads as it offers enhanced night visibility. Thermoplastic road marking machine is equipped with sensors that provides an audible warning to drivers straying out of lane. The Thermoplastic road marking material is used on motorways, dual carriageways and airfields.

...more

Road Making Machine

Road Construction Machinery

Road Construction Equipment

Mobile Crusher

We are offering mobile crushers. the portable crusher is composed of primary crusher, a portable frame or a station and a secondary chute for material discharge. we manufacture jaw crushers which has high-efficiency, multi-function, excellent crushing product quality as well as the reasonable structure design and prominent crushing characteristics. It has the strong adoption ability for the transporting quantity, material particle size and abrasiveness. It brings long wear time and higher work efficiency. The reliable and stable quality establishes the perfect reputation among all the users domestic or abroad. the size of crusher depends on the amount of production to be done and the type of crusher will depend on the material to be crushed like stone, coal, limestone, clinker, slag, dolomite and other.

...more

Skid Mounted Crushing Plant

We offers skid mounted crushing and screening plants. these are composed two stations i.e. Primary crushing and screening stations. For primary crushing, single or a set of crushers are placed on a highly integrative full-set machine frame and a vibrating screen is installed on the secondary screening station. These two frames are joined by a belt conveyor for material transition. An electrical control panel is also placed for proper controllability of all the equipments. Every station is an independent working unit. They separately perform their different responsibilities. these plants are easy to install. These machinery equipments are easily movable. They just need a concrete foundation set up. Our units meet high demands both on site and on the road establishment purposes. They are compact, very stable and of low weight. Since the different units are compatible with each other, it is easy to combine two, three or more units, depending on the production required.

...more

Mechanical Broom

Mechanical broom sweepers are the machines that are used for road sweeping by municipalities and departments of transportation. These machines have a ‘main broom’ that runs transversely from one side of the sweeper to other, such that the broom bristles contact the paved surface with the full width of the sweeper unit. Mechanical broom sweepers remain the standard for sweeping extremely heavy or packed-down material such as road millings.

...more

Horizontal Shaft Impact Crusher

We offers Horizontal Shaft Impact (HSI) crushers which are best used for primary or secondary crushing operations. The HSI consists of a horizontal rotating shaft to which a rotor is attached. The shaft is placed inside a chamber which is lined with replaceable blow bars. The material is fed into the top of the chamber where it impacts the rotor and is reduced in size. The rotor then throws the material outward against the hard wearing liner material. In this manner the material is reduced by repeated impact against the rotor and the blow bars until the desired material size is reached and it drops through a sizing device. Material sizing is achieved by rotor rotational speed and adjustment of the clearance between the blow bars and rotor. The blow bars are reversible to even out wear and are easily replaceable. HSI's offer high throughput primary and secondary crushing with good control of product size. Good choice where high reduction ratios are required. Capital cost per ton of capacity is low, however higher rotation speeds and wear will result in increased operating and maintenance compared to other types of primary crushers. HSI's work well with ore that is sticky or have high clay content.

...more

Hydraulic Mobile Crane

The crane has a pick 'n' move capacity of 9 to 16 tonnes and at 2.2 m from the centre of the front wheel, has the best lifting features. Derricking of boom and chassis articulation function are obtained hydraulically. It is fitted with water cooled diesel engine and has sufficient reserve power for its rated capacity. This crane gives very high productivity in materials handling applications and is highly useful where loads are not palletised and for working in rough terrain areas. CHM projects provides the cranes based on the latest trends in the mechanical industry.

...more

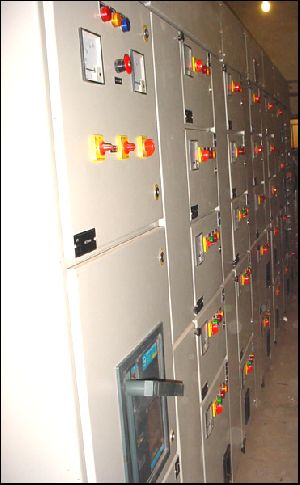

Electrical Control Panels

We are offering electrical control panels. we offer electrical control panels which consists of a fully solid state circuitry that ensures reliable supply of direct power at optimum voltage. Electrical control panels offer a reliable dc power source for smooth and continuous working of high performance rate systems. The electrical control panel consists of a capital console and several sub panels. Console contains all the fuses and all the ambit breakers. With modern electrical control panels, there is no need of transformer to transform the ac supply into dc supply. It also allows supply of current at a voltage lower than that of the main supply. In workplace where equipment with different power requirements is connected to a single circuit, the modern electrical control panel does an effective job.

...more

Electrical Control Panel

This includes and incorporates the procedures like continuous in-process reviews, visual inspection, point-to-point continuity checks, usual power test simulations. We deal in Manufacturing of electrical control panel fully customized according to customers requirements. We have a team of dedicated engineers capable to cope with the latest trends and technologies in the aforesaid arena.

...more

Double Toggle Jaw Crusher

Double Toggle Jaw Crusher features hydraulic relief, automatic oil lubrication, and automatic wedge locking systems. We deal in the installations of Fuller-Traylor single and double toggle jaw. The Toggle Jaw crusher has been of extreme use in mining industry. Double toggle jaw crushers are made up of heavy duty fabricated plate frames with reinforcing ribs throughout.

...more

Steel Fabrication Services

Metal fabrication is a value added process that involves the construction of machines and structures from various raw materials. Usually based on the engineering drawings, and if awarded the contract we fabricate the required product. fabrication shops are employed by contractors, oems and vars. Typical projects include; loose parts, structural frames for buildings and heavy equipment, and hand railings and stairs for buildings. welding is the main focus of steel fabrication. The formed and machined parts are assembled and tack welded into place then re-checked for accuracy. A fixture may be used to locate parts for welding if multiple weldments have been ordered.

...more

Wear Part Replacement Services

we offer an eminent range of wear parts for crushers and other equipments that are widely demanded in various small and large scale stone crushing units. we specialize in taking wear part replacement jobs like shaft replacement and other for the following machines : jaw crusher roller crushers vibrating screens impact crushers vibrating grizzly feeders rotopactor machines sand classifiers / screw conveyors coal crushers belt conveyors please call for any requirement.

...more

Crushing Repair Services

We have an eminent technology and workforce for repairing and machining of crushing equipments. We offer these services for the wear parts of : rotopactor machines/ roller crushers jaw crusher vibrating screens cone crushers impact crushers vibrating grizzly feeder please call for any requirement.

...more

Cargo Clearance Services

Engineering Consultants

Engineering Services

Quality Inspection Services

Be first to Rate

Rate ThisOpening Hours