Single Point Diamond Dresser

Single point diamond dressers have, undoubtedly, emerged as the most widely used diamond dressing tools. The prime reason for the popularity of these tools is the versatility offered by them, as they can be used for truing as well as dressing of grinding wheels. Manufactured using high quality raw diamond that is selected with utmost precaution, Comet single point diamond dresser is formed by either mounting a natural diamond or a bruted diamond at the top of the tool by using a special adhesive.

...more

Multi Point Diamond Dressers

Natural point diamond dresser that makes complete use of natural point angle of the diamond for truing grinding wheels. The natural point diamond dresser has many advantages such as high cleanness and hardness, no cracks, no impurities, an octahedron shape, good transparency, many natural cusps, highly durable, low waste rate. The range of natural point diamond dresser is from 0.10 Carat to 3 Carat.

...more

metal paste

Comet offers high-grade diamond lapping paste that is manufactured using qualitative diamond powder along with appropriate components, in order to ensure efficient application and achieve the desired quality of results. Available in both oil as well as water-soluble mediums, our diamond lapping paste finds application for quick polishing of all kinds of hard metals and for rendering a superior degree of finish to them. Comet's range of diamond lapping powder is extensively demanded by manufacturers of dies, seals, molds, components and other similar industries where a high degree of polish is required. Our diamond lapping powder can be made available in fine, medium and rough pastes and is packed in syringes of 5 C.C., so as to ensure easy and safe handling. To ascertain efficient application and optimum results, the work conditions and the stock to be removed are taken into consideration to determine the appropriate grade.

...more

Indexable Crown Type diamond dresser

Comet indexable crown type diamond dressers are specially recommended for cylindrical grinders and all type of large wheels where fine dressing is considered important. Comprising of several natural diamonds these multi point diamond dressers can be utilized to the maximum possible extent without requiring any resetting or re-sharpening of the diamonds used in it. The range of indexable crown type diamond dressers fabricated by us provides swift dressing and thus produces consistent and smooth surface on grinding wheels. Moreover owing to the contact of multiple diamond points with the face of the wheel, the unit pressure on individual points reduces, thereby making them more durable. Available with us are the following two types of indexable crown type diamond dressers: EM-24 with 24 Diamonds for wheel size up to 600 mm diameter wheel. EM-36 with 36 Diamonds for wheel size above 600 mm diameter wheel. Advantages of Multi Point Indexable Crown Type Diamond Dressers In this type the diamonds are mounted on a circular crown in such a manner that an angle of 90 degrees is formed between the circular crown and the operating plane. Once the diamonds get used at their current positions the crown can be readjusted on the shank and hence diamonds can be completely used up and resetting is redundant. In this dressing wheel with large area is possible in relatively shorter span of time time than single point diamond dresser. As two or more diamonds come in contact with the wheel the workload on the diamonds is divided, so the feed may be safely increased. Fine finish is obtained on the wheel due to the crystal shape of the diamonds. It can be used for side dressing of grinding wheels.

...more

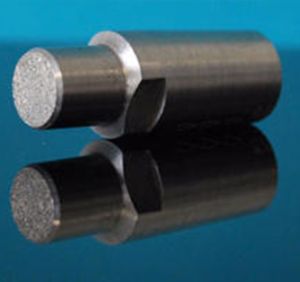

Impregnated Diamond Dressers

The diamond grit impregnated dressers offered by Comet are designed on lines similar to the multi-point diamond dressers. However, the diamond grit dressers are manufactured using crushed diamond grit instead of small natural diamonds. The grit utilised is obtained not only from natural diamonds, but also synthetic ones. It is because of the sharpness of these tools that they have been used all over the world and mainly because they are truly effective when it comes to restoring the roughness of the surface of the machine wheel. There are plenty of reasons why the diamond grit impregnated dressers are preferred over others and these include:

...more

Hardness Tester Diamond Indenter

The range of intenders manufactured by Comet Engg. Co. are utilised mainly for concluding the hardness testing on various metals as well as equipment made using metals. The intenders are designed in such a manner that the Octahedron diamond is mounted at an exact angle of 120 degrees. This ensures that there are rarely any errors, when it comes to results. Several results are obtained through the different intenders and then the same are tabulated to reach a final conclusion. The array of intenders manufactured for hardness testing are offered in several models and have been recognised for being accurate and offering errors free as well as unswerving readings. Requiring minimal maintenance and being extremely durable, the range of Comet intenders are offered in the below mentioned testing systems: Rockwell Avery Wilson Reicherter

...more

Diamond Grit Thread Dressers

COMET THREAD DRESSERSDiamond Grit Impregnated Thread Dressers Are Used For Finished Grinding. The thread dressing tools is best suitable for Profile grinding machines, screw thread and gear machines and also for tool and plain grinders. Advantages of COMET THREAD DRESSERS LIGHT DRESSING FORCE ACUTE ANGLED WHEEL PROFILE CAN BE MAINTAINED.

...more

diamond grit impregnated dressers

The diamond grit impregnated dressers offered by Comet are designed on lines similar to the multi-point diamond dressers. However, the diamond grit dressers are manufactured using crushed diamond grit instead of small natural diamonds. The grit utilised is obtained not only from natural diamonds, but also synthetic ones. It is because of the sharpness of these tools that they have been used all over the world and mainly because they are truly effective when it comes to restoring the roughness of the surface of the machine wheel. There are plenty of reasons why the diamond grit impregnated dressers are preferred over others and these include: These tools do not require any resetting, hence reducing the inventory levels. The initial cost is low, as is the cost of maintenance. The resistance towards shock as well as impact ensures that the diamond grit impregnated dressers are extremely durable. Since these diamond dressers are so adaptable, they are utilised for not only dressing the outside diameters but also the sides of grinding wheels, irrespective of them being coarse or fine. The range of diamond dressers offered by Comet finds use in areas such as: Grinding machines Tool grinders Dressing resin Rubber and vitreous bond Fine grit grinding wheels Boron carbide grinding wheels Dressing V-profile grinding wheels Dressing single profile threaded grinding wheels

...more

Natural Point Diamond Dresser

Comet offers natural point diamond dresser that makes complete use of natural point angle of the diamond for truing grinding wheels. The natural point diamond dresser has many advantages such as high cleanness and hardness, no cracks, no impurities, an octahedron shape, good transparency, many natural cusps, highly durable, low waste rate. The range of natural point diamond dresser is from 0.10 Carat to 3 Carat. Guidelines While Using Comet Natural Point Diamond Dresser To use the tool to its optimum level, it would be wise to keep the following guidelines in mind: Comet diamond dresser should be mounted firmly into the holder and, the distance between the diamond and the clamp should be reduced to the least, so as to avoid the diamond from getting ruptured due to vibration. Ensure that the diamond tool is never directed at an angle which is opposite to the direction of the rotation of the grinding wheel. To maintain a sharper point, it is essential to check that a drag angle of approximately 10 degrees to the horizontal wheel radius, pointing in the direction of grinding wheel rotation is maintained. It is important not to insert comet dressers into the grinding wheel at more than 0.001” (0.025mm) per pass. Cuts deeper than this may cause overheating and, thereby, result in excessive wearing of the diamond. A fast traverse dressing rate will produce an open wheel, enabling removal of large stock. On the other hand, a slow traverse dressing rate will impart a finish on wheel which is appropriate for producing a good finish on the work piece. In order to maintain a conical point, Comet dresser should be rotated in the holder at an angle varying from 20 to 40 degrees. To avoid cracking of the diamond, use ample amount of coolant wherever possible. Always make sure that before beginning with the cutting activity, the coolant is turned on. In cases, where dry dressing is performed, do not apply the tool incessantly for longer time, in order to avoid high temperature. Allow the tool to cool naturally instead of doing it with the aid of a coolant. A sudden change in temperature can possibly cause fracture to the diamond, essentially not at the time of shock but in the future use of the tool. A diamond dresser should never be worn down to the shank as this might result in dropping out of the diamond. Unusually, a Comet diamond dresser mounted in a dressing tool has more hidden points which, if desired, may be used by resetting. A crucial point to be remembered is not to allow a large flat to develop on the cutting point as this may deteriorate the economic life of the diamond.

...more

cluster type diamond dressers

In this variety of diamond dressers, a pair of diamonds is mounted on the tool. Primarily used for replacing single point diamond dressers, cluster type diamond dressers help in reducing the load of the diamond by bringing the pair of diamonds in contact with the wheel. These diamond dressers consist of a cluster of a variety of small diamonds arranged in a definite pattern for use with harder and coarser wheels. Cluster type diamond dressers comprise small diamond sets of 3, 5, 7, 9 and 13 diamonds forming a cluster.

...more

Chisel Diamond Dressers

Comet Chisel Diamond Dressers are manufactured using best quality natural diamonds and are preferred where accurate profiling of grinding wheels is needed. Chisel dressers are used on Diafarm, Akuform and similar machines. These tools are used for generating concave and convex radii on all wheel sizes, for contour dressing on centre-less grinders and for angle head dressing. Made from the finest quality elongated diamonds, these are lapped precisely to the required angle. All our tools are based on the highest quality natural diamonds stones. If you want maximum tool life for your Chisel dresser, choose a larger profile angle, protect, and store the tool properly when not in use.

...more

Blade Type Diamond Dressers

Blade Type Diamond Dressers are specially recommended for Angular and centreless grinders. In this non-crushed natural grains are uniformly set in a special pattern. Advantages of blade type diamond dresser: Restores the required effective roughness of the wheel surface. It is adapted to the machining operation by varying the traverse dressing feed. Complete use without any maintenance. Reduced inventory. Cost cutting upto 50% Extremely long service life and used where precise dressing of wheel is required.

...more

V Belt

Be first to Rate

Rate This