Self Aligning Carrying Roller

Get Price Quote

Self-Training Carrying Idler are installed between the normal idlers to adjust the transverse displacement caused by unevenly loading, wet condition of bottom of belt side and bad training of belt.

Impact Idler Frame

Get Price Quote

1 Piece (MOQ)

We offer an exclusive range of Impact Idler Rollers to our clientele. These products are highly used in the market for various applications. Our professionals manufacture these products employing the industry approved raw material and advanced technology. These products are highly praised in the market owing to their longer service life and low prices.

Best Deals from Conveyor Components

Conveyor Belt With Rollers

Get Price Quote

We are counted amid the quality-centric organizations and thus source the inputs only from the trustworthy sources and we offer the best quality products at very affordable prices.we are dealing in all types of alternative spare parts and widely in demand across different industries. These raw materials are checked against varied quality parameters. One stop destination for the best in class, we are a reliable Supplier amidst the customers

Stainless Steel Conveyor Roller

3,000 Per Piece

10 Piece (MOQ)

Magnetic Separator

Get Price Quote

1 Piece (MOQ)

Owing to our wide distribution network and the fastest transit system, buyers can receive their orders on timely basis. In order to keep the products in safe condition during handling, warehousing and transit, we make use of only premium packaging materials. Moreover, our skilled personnel are employed for carrying out the task of packing.

Magnetic Separator

Get Price Quote

Magnetic Separator is a basic equipment of magnetic separation technology. It finds wide usage in separating magnetite, reclaiming magnetism weight additive and preselecting wet high-intensity magnetic separation feeding act. The major advantages of Magnetic Separator are low power consumption, high magnetic induction, low cost, easy of handing, small floor space and large processing capacity. NHI China are a well-known Supplier of Magnetic Separator in China.

Conveyor Roller

Get Price Quote

100 Piece (MOQ)

Conveyor Components

Get Price Quote

We are one of the leading manufactures and exporters of a wide range of Industrial Conveyor that are widely used in the extrusion process. This wire feeder is manufactured using finest quality raw material using machines based on the latest technology and are available under the following technical specifications

chain conveyor belt

200,000 - 1,000,000 Per Piece

2000 Piece (MOQ)

Magnetic Filter

63,800 - 63,801 Per Unit

1 Piece (MOQ)

Modular Belt Conveyor System

5,000 - 80,000 Per Meter

Obtain the extensive and affordable array of products that is available from our massive inventory in Delhi(India). Each consignment of ours is packaged carefully utilizing premium packaging supplies and technologies in order to maintain the products' environment and quality during shipping and handling.

Fully Automated Magnetic Filter

687,000 Per Unit

Dek SMT Screen Printer Conveyor Belt

Get Price Quote

conveyor wheels

Get Price Quote

NKC offers a choice of two types of motors in the Motrain system: a silent inverter-type motor and a linear motor. Use of urethane rubber wheels cuts noise levels drastically. Moreover, the linear motor system offers a further advantage: the driving wheel and the rail do not come into contact with each other. That makes this system ideal for eliminating problems arising from water and oil used in the production process. The low noise levels also guarantee a pleasant working environment. And since Motrain brings what you need so quickly, when you need it, its speed reduces the noise generated even further.

Magnetic Filter

Get Price Quote

We are providing magnetic filter for food industry , pharmacutical industry and chemical and fertilizer industry.

Dry Magnetic Separator

Get Price Quote

CTL Series Dry Magnetic Separators are simple in terms of structures. They can be simply installed at the head of belt conveyors. They can also work as dry magnetic separation machines.

Conveyor belts

Get Price Quote

Conveyor Belt

150,000 Per Piece

CONVEYOR PULLEY BELT

Get Price Quote

Conveyor pulley is a mechanical device used to change the direction of the belt in a conveyor system, to drive the belt, and to tension the belt. Modern pulleys are made of rolled shells with flexible end disks and locking assemblies.

plastic roller

Get Price Quote

Vintex Rollers with time has upgraded to maintain its position as top suppliers of Rubber Rollers for almost all types of machinery for Flexible Packaging Industry. With latest equipment and gained expertise, We serve half of its total sales to the flexible converting industry.

Roller-belt Conveyors Idler & Powerised

Get Price Quote

We are offering roller-belt conveyors idler & powerised. The components of powerised idler roller conveyors model – ips-prc & ips-irc are designed to deliver heavy duty usage as well as flexibility. They comprise of broad walled rollers of sprocket (complete with torque limiting clutch assemblies), chain to chain or tangential (one common chain) chain mechanism, a fully enclosed side frame and an external shaft mounted motor. These powered roller conveyor comprises of component that are designed for both heavy duty usage and flexibility.

Adjustable Sliding Roller

150 Per Piece

Industrial Printing Rollers / Sleeves

Get Price Quote

Your Satisfaction is our Goal.Böttcher - a global market leader in the printing industry and a leading supplier of industrial rollers: a name rich in tradition that stands for continuous innovation, superior quality and comprehensive service for 70,000 customers around the world. Böttcher has been developing and producing roller coverings for a wide range of applications for more than120 years. We have acquired a broad base of complex expertise in rubber processing that is applied in one of Europe's most modern mixing plants. And that makes us one of the few competent compound producers with an in-depth understanding of the entire production chain, from intensive research and development to recipe composition to optimum compounding. Extensive experience in elastomer processing, first-class products, cost-consciousness, continuous development and a highly motivated technical field sales force - these are the success factors that translate into significant competitive advantages for our customers. To maintain an effective market presence, our customers need more. We are fully committed to these objectives: Build on our Strength for your Competitive Edge. With production facilities all over the globe and a worldwide sales and logistics network, we are there to serve you wherever you may be. Your Böttcher representative is right around the corner - with professional service and expert solutions. That saves you time and money. Our know-how is your capital. In close dialogue with users and machine manufacturers, 50 Böttcher engineers and technicians are constantly at work developing and optimizing compounds designed to meet your specific needs. Thus new solutions are constantly being developed for processes of all kinds. And the standard we apply is very simple: the most demanding requirements for the industrial application in question. And that has made us a recognized OEM supplier to leading machine manufacturers. We process and continuously monitor compounds at all sites in order to guarantee you consistently high quality and stable production at a high level of productivity - worldwide.

Conveyor Spare Parts

Get Price Quote

Wouldn’t it be more efficient to have one supplier for all your conveyor needs? Metso provides just that, with the most complete and versatile range of conveyor spare parts on the market to maximize the efficiency and safety of your conveyor operations. Whatever conveyor structure you operate, we have everything you need.

Wire Mesh Conveyor Belt

Get Price Quote

We are counted as one among the well-known manufacturer, exporter and supplier of quality assured Wire Mesh Conveyor Belt. The offered belt are manufactured by using the excellent quality raw material and ultra-modern technology under the vigilance of our adept professionals. The provided belt widely find applications in material handling, biscuit plants, food processing, etc. Additionally, these belt are available for our clients in several technical specifications to select from.

CWC Counter Top Circular Waste

Get Price Quote

FEATURES LONG LASTING LIFEFull assurance of best quality#304 grade Stainless Steel VANDAL PROOF BODYPerfect Selection of Material &design to protect from vandalism HYGIENIC ENVIRONMENTKeeps your hands andwashrrom germ free.

automatic screw feeder

94,000 Per Piece

1 Piece (MOQ)

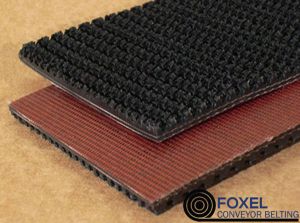

Rough Top Conveyor Belt

Get Price Quote

Available with bottom cover/bare back for use in slider bed applications Depending upon transported materials, these can handle transportation at inclination angle of 25 ~ 30 Bareback rough top belt allows less possibility of friction thus making these suitable for running over table as well as flat panel Superior finish design of mesh-like pattern on top surface cover that aids in generating relief effect while absorbing any vibrations as well as impact that is exerted on materials which are conveyed Also simultaneously helps in preventing material from slipping Some of the standard applications where these Rough top conveyor belt solutions find usage include: For transportation of light weight goods For transportation of products like sacks, boxes and parcels For transportation on inclined surface at maximum angle of 35 degrees Typical application include for belt flight loaders, lorry loaders and others For transporting light goods having movement in either inclined or horizontal Suitable for transportation of fragile/deformed materials as well as pack goods like papers, bags, glass, boxes as well as cartons to of 35 degrees maximum Construction & Properties 2 or 3 ply construction Comes with cut edges and carcass of synthetic EP fabric Superior surface texture that resists tendency for material roll back down the conveyor Black top cover recommended for utility type incline service Tan cover suggested for meeting the transportation needs for packaged food products where presence of belts having odorless non toxic finish is required Top cover comprises full 1/8 thick SBR Back of belt protected through durable friction surface bottom or through synthetic bare-back for slider bed applications

tension device

Get Price Quote

Diameter = 2.0 in, Stroke = 2.0 in, Centering Spring Force = 1100 lb, Maximum Spring Force = 2500 lb, Maximum Force = 8000 lb. Weight = 3.3 lb, Material = Titanium, non-magnetic.

BELT TENSIONER 35612031F

800 - 2,000 Per set

100 Set (MOQ)