Pfw Impact Crusher

PFW Impact Crusher Base on the plentiful experience of producing and marketing of impact crusher, SCM R&D institution designed the PFW series impact crusher. It is the newest style impact crusher and has been widely used in many industries, like chemical, metallurgy, road and bridge construction and sand making and so on. Features Advanced Manufacture process and high-end fabrication material Heavy rotor design and tight test method improve the rotor performance. Overall type cast steel structure bearing base improves anti load resistance capacity. Hydraulic jacking device and hydraulic regulated discharging port is helpful to save labor and time. Application PFW series Impact crusher are mostly used as secondary crusher and it well fits for crushing numerous medium and soft mineral &rock materials, such as limestone, feldspar, calcite, talc, barite, clay, tombar thite, kaolin, gypsum, and graphite, etc.

...more

Pe Jaw Crusher

PE Jaw Crusher PE series jaw crusher is usually used as primary crusher in quarry production lines, mineral ore crushing plants and powder making plants. It can be described as obbligato machine in mining, building construction, construction wastes crushing, Hydropower and Water Resource, railway and highway construction and some other industries. Features Simple structure, easy maintenance; Stable performance, high capacity; Even final particles and high crushing ratio; Adopt advanced manufacturing technique and high-end materials; Application Jaw crusher is widely used in various materials processing of mining &construction industries, such as it is suit for crushing granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral &rocks.

...more

Mobile Crushing Plant

K Series Mobile Crushing Plant Based on more than 30 years’ manufacture experience, millions of equipment units’ installation experience and abundant invested in research and development, SCM has released the K series portable crushing and screening plants, which contain 72 models that fit various crushing work in metal mines, building aggregates and solid waste treatment fields. Features Take advantage of the hydraulic system to control equipment installation, lifting, erection, transportation, contraction, folding and other motions to achieve simple and convenient Equipped with sustained hoisting tools, operating platform, repair kit, and centralized control system, etc., to humanize maintenance and applications The product widely adopts automotive covering parts, for example, streamlining hood design; the vehicle body sheet metal structure uses industrial aesthetic modeling to ensure specialized production of the equipment steel structure. The equipment has been optimized in structure design and product portfolio, so it has more types and more flexible combinations, able to provide users with more abundant and effective portable solutions. A water-jet dust suppression device and other relevant devices are added as options to satisfy users’ various requirements Application K series portable crushing and screening plants can not only be used for crushing, but also be used to produce high quality sand, wash sand, sharp aggregates and screen particles and some other processing work in metal mines, building aggregates and solid waste treatment industries, etc.

...more

Manganese processing plant

Manganese processing plant Manganese is essential to iron and steel production by virtue of its sulfur-fixing, deoxidizing, and alloying properties. Steelmaking, including its iron making component, has accounted for most manganese demand, presently in the range of 85% to 90% of the total demand. Among a variety of other uses, manganese is a key component of low-cost stainless steel formulations. Small amounts of manganese improve the workability of steel at high temperatures, because it forms a high melting sulfide and therefore prevents the formation of a liquid iron sulfide at the grain boundaries. Manganese processing equipment There is a manganese production line provided by SCM in Mexico. This production line is the whole manganese process line, which can product 100t manganese per day. SCM design all the line and supply PE Jaw Crusher for primary crusher and HPC Cone Crusher for secondary crusher. Beside, SCM Vibrating Feeder and Belt Conveyor is used in the line. SCM is a professional manufacturer of manganese crushers and manganese grinding mills. Manganese processing flow The manganese testing is the first step of mining manganese, in which the manganese ore test machine is necessary. After manganese tested, manganese mining and processing methods include mechanical separation, which includes ore crushing, washing, screening, gravity separation, high-intensity magnetic separation and flotation separation, pyrometallurgy enrichment and chemical mineral processing method and so on. SCM Machinery can design all process line and supply good quality crusher to crush manganese ore, washing machine to wash manganese ore and vibrating screen to screen .

...more

Limestone Grinding in Belgium

Limestone Grinding in Belgium In modern industries, powder has widely application and powder making industry has become one high value-added industry. As professional milling machine manufacturer, SCM has helped great many customers from different countries solve their problems and build powder making plants. Customer's Background: A material supplier from Belgium would like to produce limestone powder for his customer, one paper making company. The capacity of the milling plant should be able to reach 3-5 tons per hour, and the final powder size should be as D90=105μm.

...more

Granite Crushing Plant

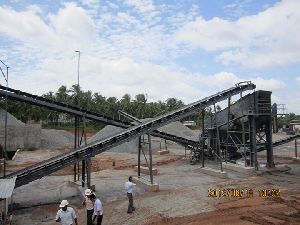

Vietnam 300TPH Granite Crushing Plant Vietnam is an important mining export country in Asia, especially the exportation of Limestone, iron ore, coal, granite and bluestone products. With many years’ effort, SCM successfully developed Vietnam market, SCM crushing machineries and milling equipments are very popular in many provinces, like Yen Bai province, Ho Chi Minh City, Nghe An, Tỉnh Quảng Ninh and Hanoi. These mining equipments make up various mining crushing lines, sand making plants and mineral powder production bases. Customer's Background: At the beginning of 2012, SCM salesman got one phone call inquiry from Vietnam Yen Bai, expressing that he visited one superfine limestone powder production line designed by SCM and he would like to know more about SCM. The Salesman Anne warmly welcome him visit SCM head-office and carefully help him analysis his requirements. After many negotiations, SCM design, 300TPH granite crushing plant, is highly-prized by the customer

...more

Feldspar stone processing plant

Feldspar stone processing plant Feldspar is the most common ore in the earth crust and it even appears on the moon and in the aerolite. In some parts of the earth crust, 15km under the earth’s surface, feldspar accounts for 60%. Feldspar is the main component of igneous and is also common in metamorphic rock and sedimentary rock. Feldspar processing equipment Typically, jaw crusher is used in the primary crushing, and the impact crusher is used in the secondary crushing. Usually, according to the quarry conditions, mobile crushers are also used in the feldspar quarrying. To produce feldspar powder, the grinding mill is a necessary machine. including the ball mill, Raymond mill, vertical mill, trapezium mill, coarse powder mill, and ultrafine mill, etc. Feldspar processing flow The process of feldspar crushing is consisted of primary crushing and secondary crushing. After the two stages of feldspar crushing, large feldspar whose diameter is approximately 1.5 meters has changed into feldspar particle, and the size of feldspar particles can achieve to 25mm or less. In the grinding process, crushed feldspar particles is grinded into powder with the fineness requirement of 200 mesh by grinding mill.

...more

Copper Ore Crushing Plant in Chile

Copper Ore Crushing Plant in Chile SCM set up a local branch office in Chile, which is one of the most important sales markets of SCM in South America. Each year, a large number of clients purchased crushing and powder-making machineries produced by SCM, and we have won trust from our clients because of the high-quality products and after-sales services. Customer's Background: In 2011, the clients contacted our sales person in Chile branch office. The clients wanted to set up a copper ore crushing plant with the following requirements:

...more

concrete tools

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in standard sizes of the final products between 0.074 mm and 0.4 mm in diameter.The capacity and fineness can be adjusted by adjusting the diameter of the ball.

...more

Calcite mining and processing plant

Calcite mining and processing plant SCM Machinery is professional manufacturer of calcite Crusher and Calcite Grinder Mill. It supplies all kinds calcite crusher equipment and design calcite crushing & grinding production line according to the requirements of customers. Our calcite Crusher have exported to South Africa, Kenya, USA, Australia, Zimbabwe, Russia, etc. Calcite processing equipment SCM calcite pulverizers include calcite crushers and calcite grinding mills. calcite crushers includes Jaw Crusher, Cone Crusher, Impact Crusher and Mobile Crushing Plant, which is used to crush the big calcite block to smaller. SCM grinding mills include Ball Mill, Raymond Mill, MTM Trapezium Mill, Super-Micro Powder Mill and Coarse Powder Grinding Mill, which is used to grind the crushed calcite block to fine powder. You can choose suitable calcite pulverizers depends on your calcite size, hardness, capacity and your cost budget. Calcite processing flow Raw calcite first enter calcite crushing plant to be crushed to smaller size. The calcite crushing plant consists of jaw crusher, cone crusher, impact crusher, belt conveyor, vibrating screen and vibrating feeder. Then they are lifted to storage room by elevator. Vibrating feeder will feed materials into calcite grinding mill evenly and gradually. After being grinded, the calcite powder will be blowed to cyclone by blower. Then the calcite powder will be transferred to storage room through pipes, and then will be discharged as final products. Sometimes the crushing process is not necessary, sometimes grinding process is not necessary.

...moreBe first to Rate

Rate ThisOpening Hours