wobbler feeders

Material handling unit to feed and separate (scalp) a variety of feed materials. Over 650 units installed. Features Incredibly reliable material handling unit designed primarily to handle wet, sticky materials where a separation is required Jog reverse function if jamming should occur Variable speed drives Automatic lubrication system.

...more

wire systems

Metso wire media systems offer the latest innovation in wire screening media, Trellex PCL (PolyClean), designed to improve your aggregate production. Features The Metso wire screening media system, Trellex PCL (PolyClean) is the solution you have been waiting for. This wire media enables you to screen your material efficiently even in the most demanding conditions. Even when your feed is sticky or prone to pegging, Trellex PCL will screen it. Combining the wear resistant properties of polyurethane with the open area of wire media, Trellex PCL provides increased wear life and capacity compared to classic wire.

...more

Wear Lining

Mining, aggregate and cement applications are tough on equipment, which can make it even tougher on budgets. Keep material flow up and maintenance time down with a range of wear lining products designed to maximize productivity and profit.

...more

VisioRock analyzer

The crushing quality can be easily measured with Metso’s VisioRock™ photo particle size analyzer that is connected to the IC crusher automation. VisioRock Compact is the latest version of the system Metso has developed to measure real-time production. Its compact design, easy installation and Modbus interface enable quick access to particle size distribution from cameras above the conveyor belt.

...more

Vibrating Screens

Metso MF Series (Multi-Flo) vibrating screens, generally referred as banana screens, are specially suited for large material volumes with a high percentage of undersize product in the feed material.

Feature : Linear motion screen with multiple curved decks Screen body easily prepared for dust encapsulation High screening efficiency with less square meters

...more

Vibrating Screen

Screen primarily used as a low tonnage trash screen with excellent results in dewatering. Features Compact design Very easy to install in most circuits Unbalanced motors add to the ease of installatio.

...more

vertical shaft impactor (VSI) plants

Metso NW Series™ portable VSI plants are built around Barmac® B Series™ Vertical Shaft Impactor (VSI). Barmac is the original rock-on-rock impactor. It has become synonymous with high-quality products in quarrying and minerals processing industries. The crushing process makes Barmac VSI unique. Whereas most other types of crushers use metallic parts to crush rock, Barmac VSI uses the rock fed into the machine to crush itself. This autogenous crushing action offers the lowest possible cost per ton of any impact crushing method. The high velocity impact crushing achieved in a Barmac VSI improves the soundness and shape of the material and produces the highest quality end products on the market today. It is widely known that the more cubical your product, the better its performance in concrete, asphalt and base mixtures.

...more

Vertical shaft impact

Barmac® B Series™ Vertical Shaft Impactor (VSI) is the original rock-on-rock impactor. It has become synonymous with high-quality products in quarrying and minerals processing industries. Features The crushing process makes Barmac® VSI unique. Whereas most other types of crushers use metallic parts to crush rock, Barmac VSI uses the rock fed into the machine to crush itself. This autogenous crushing action offers the lowest possible cost per ton of any impact crushing method. The high velocity impact crushing achieved in a Barmac VSI improves the soundness and shape of the material and produces the highest quality end products on the market today. It is widely known that the more cubical your product, the better its performance in concrete, asphalt and base mixtures.

...more

valve spare parts

Use genuine spare parts designed for your process to ensure safe operation, a long operating life and an efficient process. Features Metso spare parts are made to meet original material and specification requirements as used in original valve or accessory. Metso spare parts are manufactured to include latest design changes. By using Metso spare parts, you have the assurance that the spare part is designed for your specific process, certification will be maintained and maximum equipment lifetime achieved. Original Metso spare parts ensure that wear and maintenance costs are kept to a minimum.

...more

Valve controls switches

High availability and easy interpretation are the key success factors in effective field device data analysis. Metso is committed to supporting open and standardized technologies. We can offer the best field devices and ensure the availability and usability of diagnostics information independent of your control, safety or asset management system.

...more

V-port segment valve

Neles R-series V-port segment valve is an economical high performance control valve designed for liquid, gas, vapor and slurry control applications - especially with high capacity and wide rangeability requirements. R-series offers light weight, low torque control valves from 1" low capacity models up to 32". Features Real one piece body without inserts or seat retainers eliminates possible leak paths and bending forces from piping ensuring reliable valve operation. Anti-blowout shaft. Rotating, dynamic Q-trim attenuator for anti-cavitation and noise abatement. Low emissions according to ISO 15848 with wide temperature range and the longest endurance class. Fire safe certification according to API 607, 6th edition.

...more

UltraFine Screens

The new Metso UltraFine high frequency vibrating wet screen is designed for separation from 0.075 to 1 mm, and is an ideal alternative to hydrocyclones by providing greater separation and energy efficiency. The UltraFine Screen addresses all of the challenges of previous fine wet screening technologies, enabling our customers to broadly implement this technology to improve their profitability.

...more

Trellex wear sheeting

Installing Trellex rubber wear sheeting from Metso is identical with good operating economy and reduced risk of breakdowns. Features Trellex rubber wear sheeting has proved a long wear life compared to other material. The result is that you simply don't need to change lining as often. Fewer stops and less production losses increases your profitability.

...more

Trellex wear elements

Trellex wear elements include a wide range of basic wear plates manufactured in rubber or polyurethane. The wear elements provide first class protection in applications that are subject to wear and noise. Features Metso offers a complete range of wear plates when it comes to sizes, thicknesses, fixing systems etc enabling us to provide you with the most suitable product for your application.

...more

Trellex SQ300 recyclable modular system

Trellex SQ 300 is a completely recyclable modular system for wear lining. What makes the difference? Quite simply, it is designed without fabric or steel reinforcements - something few other wear protection products on today’s market can claim. Features At last, the mining and aggregates industry has access to a modern, environmentally friendly wear lining system. Its main purpose is to reduce impacts and improve health and safety in a variety of important ways - all without increasing costs or sacrificing operational efficiency. Suitable for use in mining chutes, transfer points and other areas subject to wear, SQ 300 provides excellent protection in many applications, keeping material flow up and maintenance time down.

...more

Trellex Poly ceramic lining

The combination of the best properties of rubber and ceramics in our linings ensures an extra long life cycle compared to other wear protections. The high quality ceramics provide unique resistance to wear, while the elastic properties of rubber effectively absorb shock impacts. Features:- Trellex Poly-Cer is our ceramic lining designed to be extremely resistant to abrasion even in high material flows and speeds. Trellex Poly-Cer provides excellent wear protection for feeders, bins, transfer chutes, silos and any other application that are subject to heavy wear and noise.

...more

wobbler feeders

Mine or quarry-run material is dumped on the elliptical bars. As the bars turn, fines, mud or dirt drop through the openings. Oversize or unwanted waste materials move forward in a rocking roller motion. The opening between the bars remains constant as the bars rotate. Ribs on the bars reduce the amount of large elongated pieces of material from passing through.

...more

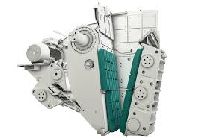

The ultimate primary crusher

The Nordberg C Series jaw crushers are overhead eccentric single toggle jaw crushers. The feed material is crushed between fixed and movable jaw dies. Movable jaw die is mounted to the pitman. Pitman motion (=kinematics) is defined by the eccentricity of the eccentric shaft and by the angle of the toggle plate. In Nordberg C Series jaw crushers the angle of the toggle plate is so steep that it amplifies the stroke from the top of the cavity to the bottom of the cavity. The result is a long and linear stroke in the bottom of the cavity which ensures great productivity and high reduction ratio.

...more

SwitchGuard

Metso's Neles SwitchGuard is a top class intelligent onoff valve controller designed to operate on any valve actuator. Large pneumatics capacity and embedded diagnostic features enable users to guarantee the availability of their switching and high cycling valves in demanding processes. Features SwitchGuard’s pneumatic capacity easily replaces any solenoid valve and other pneumatics accessories, providing a simple and reliable interface with the process control system. Programmable speed control enables adjusting the openingclosing times easily and provides trouble free long term valve operation. Diagnostic information is presented in easily understandable way to enable planned maintenance of potentially failing valve assemblies before they have chance to impact on the process.

...more

standard port flanged valve

s V-port segment valve is an economical high performance control valve designed for liquid, gas, vapor and slurry control applications - especially with high capacity and wide rangeability requirements. R-series offers light weight, low torque control valves from 1" low capacity models up to 32".

Feature : Real one piece body without inserts or seat retainers eliminates possible leak paths and bending forces from piping ensuring reliable valve operation. Anti-blowout shaft.

...more

Standard Port Ball Valve

Thread end connection resilient seated 2 piece ball valve Features Robust engineering design Manual operation High quality

...more

Conveyor Spare Parts

Wouldn’t it be more efficient to have one supplier for all your conveyor needs? Metso provides just that, with the most complete and versatile range of conveyor spare parts on the market to maximize the efficiency and safety of your conveyor operations. Whatever conveyor structure you operate, we have everything you need.

...more

Slurry Pumps

When it comes to pumping abrasive slurries it’s not a question of if you will need spare and wear parts – it’s a question of when. With fully integrated systems and single source supply solutions we simplify the inventory, distribution and installation of spares and wears to keep our customers’ processes running longer, safer and more efficiently.

...more

Screening media

Whatever the application, there is a Metso screening media solution to match. Metso screening media are adaptable to all environments and tasks. The range is designed to offer maximum productivity without compromising quality.

...more

Wear Parts Optimization

Shutdown and Wear Parts Optimization package ensure that everything goes well during major shutdown events carried out for maintenance purposes, and that your equipment gets back up and running safely and quickly. Features An LCS Shutdown and Wear Parts Optimization solution means you get one supplier performing all components of a shutdown from start to finish. With this package, we take responsibility for reducing your downtime due to shutdowns over the life of the contract. We also look to improve your efficiency by optimizing your wear parts for longevity and their highest production capacity. When you sign on, we�ll give you everything you need, backed by commercial terms and payment plans that work for you. Shutdown and Wear Parts Optimization package Level 2 gives you: 1. Scheduled inspections 2. Wear parts design, supply and optimization 3. Shutdown planning, execution and follow-up 4. Wear and spare parts inventory.

...more

Metso valve selection software

Metso has released Nelprof 6 valve sizing software. The new version extends earlier Nelprof� versions with two new calculation modules, which enable the selection of intelligent automated onoff valves and emergency valves. Special safety requirements, such as an actuator-sizing safety factor or a complete valve-assembly safety-integrity level, can be evaluated with the new state-of-the-art tools in the program. Features Nelprof, with its advanced control-valve selection features, was first introduced in 1981. Now Nelprof 6 can be used to select all Metso�s automated onoff and emergency valves. Performance analysis, which has been one of the value-adding features in the control-valve sizing tool since 1980�s, can be used to study valve controllability in a closed control loop. The module also includes multi-phase flow sizing as well as noise and cavitation prediction analysis.

...more

Metso Metrics Services

Under our Life Cycle Services offer, Metso Metrics Services is now available for our aggregate customers. Comprised of a cloud-based, remote monitoring and data visualization service for Metso Lokotrack® mobile crushing plants, you gain critical data and insight on your fleets operational performance and maintenance needs. Features You aim for high utilization rates and optimized production from your equipment. However, managing your crushing assets, whether it is a single machine or a fleet working at multiple sites can pose challenges. With mobile crushers often located at remote locations or being moved between production sites, it can be difficult to track and interpret the operating condition and performance of your equipment. In addition, managing maintenance schedules for multiple different machines and ensuring the right wear and spare parts are on hand when you need them can be problematic. Extended downtime and lower production can result if the right steps are not put in place.

...more

device management

Installed Base Analysis

Be first to Rate

Rate This