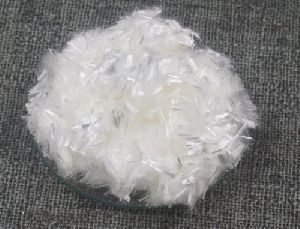

Polypropylene Fiber

Get Price Quote

5 Ton (MOQ)

Application Area: Addition of fibres results in increase in tensile strength and flexural strength. Hence it is ideal for seismic designs and high strength concrete. Consumption Area: For Crack prevention- 500 -1000gm/m 3 ; For Fire Protection of Concrete:- 1.0– 3.0 Kg/m 3 As primary reinforcement: - 1.– 4.0 Kg/m 3 (depending on conditions required.)

Mortar Polypropylene Fiber

135 Per Kilogram

1000 Kilogram (MOQ)

Best Deals from Polypropylene Fiber

Polypropylene PP bristle filaments

250 - 275 Per Kilogram

500 Kilogram (MOQ)

we are a well-known manufacturer, exporter and supplier of pp bristles. the pp (polypropylene) bristles offered by us are extensively demanded in industries all across the world for manufacturing industrial and household brushes. the pp bristles possess excellent chemical stability and also come with good uv stability. we supply premium quality and durable pp bristles at fair prices.

Polypropylene Fiber

200 Per Kilogram

200 Kilogram (MOQ)

polypropylene fibre

Get Price Quote

Bajaj Polypropylene Fiber

250 Per Pack

10 Pack (MOQ)

Polypropylene Construction Fiber

Get Price Quote

1 Ton (MOQ)

Polypropylene Fibres

Get Price Quote

Polypropylene Fibre are precision cut polypropylene fibres which are used in mortars and in concrete to produce crack free and durable wall plasters, concrete panels and durable floor screeds. Fibres are milky white strands of poly propylene supplied in 6 mm and 12 mm lengths. The smaller 6 mm ones are used in plaster mixes whereas the longer 12 mm ones are used in concrete.Features:Fibres are used as an additive in mortars for making crack free internal and external plasters of buildings. Fibres are also used as an admixture in floor screed concrete for making crack free and aberration resisting floors. As a secondary reinforcement, in large bays of concrete to get over surface cracks.

Monofilament Concrete Polypropylene Fiber

180 Per Kilogram

500 Kilogram (MOQ)

Polypropylene Synthetic Fiber

208 Per Kilogram

100 Kilogram (MOQ)

Polypropylene synthetic Construction Fibers available in various length, 6mm, 12mm, 18mm etc. packaging available 900 grams or Bulk Gony packaging

PP Macro Fiber

Get Price Quote

Polypropylene Fiber

40 Per 100 Gram

10 Kilogram (MOQ)

Polypropylene Fibre are used in construction for mixing in cement which reinforces concrete. hich reduces rebound losses by 60%-70%. Improvesnspeednand finish of plastering. Reduces shrinkage and cracks. Improves waterproffing ability of plaster.

Crack Resistant Polypropylene Fiber

100 - 200 Per Kilogram

Polypropylene Construction Fibres

220 Per Kilogram

Monofilament Micro Fiber

90 - 149 Per Kg

200 Kilogram (MOQ)

Jayma International Glass Fiber are an advanced version of Reinforcement Fiber for Crack Reduction and Micro Secondary Tensile Reinforcement. There are varieties of Fibers available in the International market, Our Fibers are Imported, Manufactured, and Supplied with Advance Technology for Crack Reduction and Micro Secondary tensile Reinforcement. We have full range of Glass Fiber Including Industrial Grade, AR Fibers, GRC etc

polypropylene fibre

Get Price Quote

We are one of the respected names engaged in the process of supplying quality Polypropylene Fibre at nominal rates. With excellent storage space and shipping facilities, we effortlessly entertain bulk requirements of our respected patrons. We maintain complete records and transactions of the products delivered. Our Polypropylene Fibre has a crystalline surface and is available in various diameters.

Polypropylene Fiber

Get Price Quote

We offer Polypropylene (pp)Fibers (Euro Faster), is a technologically advanced polypropylene fiber specifically engineering for use in concrete, cement mortars, and ready made mixtures. It is coated with a special solution that leads to improvement of the concrete quality with respect to micro crack reduction,comprehensive strength, crack tensile strength, flexural and abrasion resistant. Used everywhere, where cements can be used

Polypropylene Fiber

Get Price Quote

We bring forth high quality Polypropylene Fiber that is manufactured as per set industrial standards. The Polypropylene Fiber offered by us, is known for its high strength and durability.

Micro Pp Mesh Fiber

Get Price Quote

1 Metric Ton (MOQ)

Durocrete tm fibrillated polypropylene fibers employ a unique technology that creates additional micro fibrils attached to the primary fibrillated network. These offer more adhesion points that increase bonding between the mortar matrix and the fiber network. The resulting network increases concrete compressive and tensile strength providing excellent shrinkage and temperature (secondary) reinforcement. Additionally, durocretetm fibrillated has excellent finishing properties. Durocretetm fibrillated fibers are a cost-effective alternative to light gauge welded wire fabric (wwf). The fibrillated strands prevent 80-100% of all cracks in the plastic state–precisely when most cracks occur. Fibrillated complies with astm c 1116/c 1116m, type iii. benefits: • saves construction and placement time, especially for laser screed operations • increases crew safety by eliminating wire mesh handling • reduces long term cracking • improves residual strength • improves green strength applications: can be used for all residential flatwork as well as light duty commercial floors including: • slabs on grade (driveways, patios, walkway) • standard commercial floor traffic such as stores, hospitals, offices • concrete toppings of precast panels • stair pans and basement floors • shotcrete and tunnel linings, slope stabilization.

Polypropylene Fiber

190 - 210 Per Kilogram

1000 Kilogram (MOQ)

pp fiber

Get Price Quote

Polypropylene macro Fiber

170 - 180 Per kg

500 kilogram (MOQ)

Crackstop Monofilament Polypropylene Fibres

Get Price Quote

The Crack stop range of monofilament polypropylene fibres reduce the occurrence of plastic shrinkage and plastic settlement cracking, whilst enhancing the surface properties and durability of hardened cementitious products. Crack stop fibres are extremely fine, single filaments, cut to lengths of either 3, 6, 12 and 18 mm. Some fibre types also have blended lengths. The fibres are coated with surfactant to improve initial dispersion within the cementitious materials.Advantages & Benefits Reduced plastic shrinkage cracking Reduced explosive spalling in fire Alternative to crack control mesh Improved freeze/thaw resistance Reduced water & chemical permeability Reduced bleeding Reduced plastic settlement cracking Increased impact resistance Increased abrasion properties General Applications Internal floor slabs Concrete framed buildings External hard standings Bridges Underground construction Agricultural areas Self compacting concrete & screeds Water retaining structures Repair materials Pattern imprinted concrete Precast concrete Extruded concrete Piling concrete Shotcrete/gunite Mixing Directions : Crack stop fibres should ideally be added at the batching plant although in some instances this may not be possible and addition at site will be the only option. If mixing at the batching plant, fibres should be the first constituent, along with half the mixing water. After all the other ingredients have been added, including the remaining mixing water, the concrete should be mixed for a minimum of 70 revolutions at full speed to ensure uniform fibre dispersion. In the case of site mixing, a minimum of 70 drum revolutions at full speed should take place.Packing & Dispensing : Crack stop fibres are packed in the desired measured quantities in either degradable/pulpable paper bags or plastic bags. The paper bags can be added to the truck or plant mixer unopened. Plastic bags will need to be opened and the fibres added manually. Bagged fibres are placed in boxes for ease of handling. Crack stop fibres can also be ordered in bulk quantities and packed in boxes or super sacks of various sizes between 20-200 kg. The larger units are specifically designed for projects where fibre dosage machinery is available.Storage : Crack stop fibres must be stored on a clean surface, in dry conditions, under cover and away from the possibility of damage.Quality Assurance : The Quality Management Systems of facilities have been approved to the ISO 9001 Quality Management System Standard. Certificates are available on request. Products are manufactured to exacting standards on technologically advanced production and packaging lines, which allow constant monitoring of quality. Quality audits are conducted at our manufacturing plants.Technical Advice : Our technical specialists are available to assist you in the correct use of all products.Design Service : For all concrete floor design requirements please consult your representative.Total Solution Provider : We offer a full design service for products. Our expertise and knowledge of the construction industry means that we can offer our customers bespoke solutions in terms of engineered proposals, concrete mix designs, packaging configurations, high standards of distribution and fibre dosage equipment.

polypropylene fibre

200 Per Bag

100 Bag(s) (MOQ)

Give them the additional strength Secondary reinforcement fibre for concrete, in wet laid non-wovens, paper and lead acid batteries. BENEFITS OF PP FIBRE Improves resistance to plastic & drying shrinkage/cracking • Inhibits propagation of micro-cracks and provides stability to concrete • Improves flexural toughness/increases split tensile strength • Enhances abrasion resistance and increases energy absorption of concrete, thereby improving impact resistance • Aids in making concrete more homogenous • Reduces permeability in concrete • Improves durability and enhances the longevity of the structure

pp fiber

Get Price Quote

Polypropylene Fiber

Get Price Quote

The polypropylene fibers are hydrophobic, which do not absorb the water, and are non-corrosive. Moreover, the polypropylene fibers have excellent resistance against alkali, chemicals and chloride and have low heat conductivity. By these characteristics polypropylene fibres have therefore no significant effect on the water demand of the fresh concrete. They do not intervene the hydration of cement and hence do not influence unfavorably the effects of all constituents in the concrete mixture.

Polypropylene Construction Fibers

Get Price Quote

Polypropylene construction fibers are used as a concrete additive to increase strength and reduce cracking and spalling. In some areas prone to earthquake, polypropylene construction fibers are added with soils to improve the soil's strength and to prevent damping when constructing the foundation of structures such as buildings, bridges, etc. These fibers are mainly used in the plaster coat. Being a prominent polypropylene construction fibers manufacturer and supplier, our company is indulged in offering premium grade polypropylene construction fibers for our buyers. The offered fibers are resistant to alkaline materials and resistant to the natural threat. They are helpful in controlling cracks, reducing seepage and water permeability. Furthermore, the offered product is reasonably priced to make it accessible by everyone.

Polypropylene Construction Fibres

Get Price Quote

PP Long Glass Fibre

Get Price Quote

We are renowned Manufacturer and Supplier of PP Long Glass Fibre from Mumbai, India. Our dexterous team employs good manufacturing practices in fabrication of the PP Long Glass Fibre in order to meet or exceed the expectations of our valued clients. Further, we offer the quality-tested and securely-packed PP Long Glass Fibre across the nation at competitive prices. Shipping delays are never caused, courtesy our developed logistics network.

Polypropylene Fiber

235 Per Kilogram

10 Kilogram (MOQ)