Water Purifier

We offer an extensive array of water purifiers for finest purification of water through uv technology. Ultraviolet radiation is used to kill the deadliest microorganisms through a 5- stage purification system present in our water purifier system. We design and manufacture the water purifiers using latest techniques to provide several features, making the purification of water safer and easier. Due to the quality offered by us in this range, we have become a much sought after water purifiers exporter from india. We offer three types of water purifiers namely domestic water purifiers and mineral water purifier.

...more

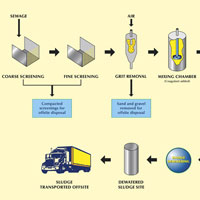

Sewage Treatment Plant

We offer technically advanced sewage water treatment plant, which is used to treat large amount of sewage effectively. With a combination of several steps, our sewage water treatment plant treat the toughest sewage without using much power. The designing of the plant is done by experienced personnel to make them ideal for repetitive usage.

Brand Name : AT/SWTP

...more

packaged drinking water plant

We are a well-known packaged drinking water plant manufacturer and exporter, bringing forth a wide range in the market. Fitted with high-efficiency equipment and backed by latest technology, our packaged drinking water plants are known for producing water in its purest form. The packaged drinking water plant is tested on various industry parameters to give best output for a long time. attributes easy to operate effective performance free from corrosion attack kills deadly pathogens removes harsh chemicals durable finds application in food processing industry plastic industry pharmaceutical industry chemical industry college labs

...more

jar plant

Product Description : Treatment for drinking water production involves the removal of contaminants from raw water to produce water that is pure enough for human consumption without any short term or long term risk of any adverse health effect. Substances that are removed during the process of drinking water treatment include suspended solids, bacteria, algae, viruses, fungi and minerals such as iron and manganese. The processes involved in removing the contaminants include physical processes such as settling and filtration, chemical processes such as disinfection and coagulation and biological processes such as slow sand filtration. Measures taken to ensure water quality not only relate to the treatment of the water, but to its conveyance and distribution after treatment. It is therefore common practice to keep residual disinfectants in the treated water to kill bacteriological contamination during distribution. WHO guidelines are a general set of standards intended to apply where better local standards are not implemeted. More rigorous standards apply across Europe, the USA and in most other developed countries. followed throughout the world for drinking water quality requirements. Processes Empty aeration tank for iron precipitation Tanks with sand filters to remove precipitated iron (not working at the time)A combination selected from the following processes is used for municipal drinking water treatment worldwide: Pre-chlorination for algae control and arresting biological growth Aeration along with pre-chlorination for removal of dissolved iron when present with small amounts relatively of manganese Coagulation for flocculation or slow-sand filtration Coagulant aids, also known as polyelectrolytes – to improve coagulation and for more robust floc formation Sedimentation for solids separation that is removal of suspended solids trapped in the floc Filtration to remove particles from water either by passage through a sand bed that can be washed and reused or by passage through a purpose designed filter that may be washable. Disinfection for killing bacteria viruses and other pathogens. Technologies for potable water and other uses are well developed, and generalized designs are available from which treatment processes can be selected for pilot testing on the specific source water. In addition, a number of private companies provide patented technological solutions for treatment of specific contaminants. Automation of water and waste-water treatment is common in the developed world. Source water quality through the seasons, scale and environmental impact can dictate capital costs and operating costs. End use of the treated water dictates the necessary quality monitoring technologies, and locally available skills typically dictate the level of automation adopted.

...more

Iron Removal Plant

We are offering iron removal plant. Raw water generally contains soluble iron in the form of ferrous bicarbonate and insoluble as ferric hydroxide. Water containing ferrous bicarbonate is clear when drawn from a tube well. But as soon as it comes in contact with air develops a whitish haze which on longer standing turns yellowish and then forms yellowish to radish-brown deposits of hydrated ferric oxide, some of this deposit sticks to the side of the container and the rest sinks to the bottom. Such water is not safe for use and has discoloration with visible iron precipitates that need to be removed. We offer modernized systems for effective removal of iron in the form of iron removal filters. The complete production is carried out under a strictly quality controlled process that involves the use of finest raw materials. oxidation of iron removal filter : aeration chamber ferrous bicarbonate is usually accomplished by dissolved oxygen introduced into the water by aeration as per following reaction : 2 fe (hco3)2 + 1/2 o2 + h2o → 2 fe(oh)3 + 4co3 from the above reaction it appears that 1ppm of dissolved oxygen oxides 7ppm of ferrous iron as fe. As solubility of oxygen from air dissolved in water at 60 f is 10ppm, theoretically water saturated with dissolved air contains enough oxygen to oxidize 70ppm, of ferrous iron. water directly from tube well is first passed into the aeration chamber packed with manganese base catalyst. Before entering into the aeration chamber air is injected with water from an air compressor. Here, according to the above reaction, iron is oxidized into ferric form. Water is then passed through the iron removal filter packed with catalyst filtering media. Here the residual ferrous iron is oxidized into ferric and entire precipitated ferric hydroxide is filtered out. the precipitated and entrapped ferric hydroxide is then removed from bed during back washing. filtration process chlorine dosing system (cl2) filtration stage backwash process pipe line process specialty resistant to corrosion durable reliable performance easy maintenance economical operation finds application in industrial sector commercial sector domestic sector

Brand Name : APEX

...more

Effluent Water Treatment Plant

We are engaged in offering effluent water treatment plant that takes care of industrial and commercial effluents. The effluent water treatment plant is manufactured using latest technologies to have a simple yet very effective effluent treatment process. Tested to adhere to the industry standards, the effluent water treatment plants we offer are widely acclaimed for fitted with sophisticated equipment for better output.

Brand Name : APEX

...more

Drinking Water Plant

BOTTLED WATER MANUFACTURING PLANT Water Purification Plant is designed to produced 5000 LPH PROCESS >> Oxidation Chamber: To convert Ferrous Iron to Ferric form. Pressure Sand Filter: To remove suspended matter from the water. Activated Carbon Filter: To remove color, odor & smell from the water. To remove oil & grease from the raw water. To control BOD & COD in the raw water. Antiscalant Dosing System: To save Membrane elements from scale deposition & chocking due to scale. Micron Filtration: To remove micron particles from the raw water. Osmotic pressure system (High Pressure Pump) To create osmotic pressure in the raw water.Desalination System by Reverse Osmosis Membrane Element. To desalt the raw water i.e. to reduce total dissolve solids. Ion Controlling System. To adjust the minerals contains in process water by means of mixing of raw water in the desalted treated water. Due to propionate mixing required quantity of raw water, we can mix to get required quantity of ions from raw water to desalted water.Storage of Mineral Water. To remove back pressure in R.O. Membrane elements.Fine polishing filtration.To filter water from 1 to 0.5 micron and achieve crystal clear filtered treated water. U.V. System. To kill the bacteria from the fine water. elements. Ozonization. To prevent biological and micro organism growth in the stagnant water. Final treated water transfer pump. To transfer crystal clear & bacteria free mineral water for Packing / Bottling. Re-Circulation of mineral water for Ozonization. To re-circulate and add ozone in mineral water. FLOW CHART OF DRINKING WATER PLANT SCOPE OF SUPPLY Water Storage Tank ,Transfer Pump ,Pressure Sand Filter ,Activated Carbon Filter ,Antiscalant Dosing ,Micron Filtration System ,High Pressure Pump System ,Desalting Process ,Mixing Process ,Storage of Treated Water Polishing Filtration ,U.V. Disinfection System ,Ozonization System ,Pet Preform Manufacturing, Bottle Rinsing, Filling & Capping ,Pet Bottle Blow Moulding ,Box / Carton Packing Machine.

...more

Dialysis Water Treatment Plant

We are engaged in offering dialysis water treatment plant that is designed for various water treatment needs across different segments. The dialysis water treatment plant is engineered by experts to provide hassle-free treatment using latest processes for step-by-step removal of impurities. The dialysis water treatment plant.

Brand Name : APEX

...more

Packaged Drinking Water

Reverse Osmosis System

Water Purifiers

Be first to Rate

Rate ThisOpening Hours