Plastic Injection Moulding Services

Get Price Quote

We are one of the renowned Service Providers of Plastic Injection Moulding Services. We are engaged in offering a comprehensive range of Plastic Injection Moulding Services of Moulded products up to 400gms to our clients at competitive market prices. With the aid of our skilled professionals, we are able to offer customization in terms of dimensions, shapes, and sizes as required by the customers. We offer Plastic Injection Moulding Services within stipulated time as per clients’ requirements. Owing to our qualitative service, we are able to garner huge clientele; our clients are from different sectors like households, medical equipment, industrial packing etc.

Reverse Engineering Services

Get Price Quote

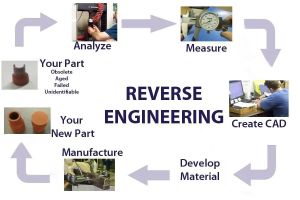

Our reverse engineering services unlock the secrets of existing products or systems, offering valuable insights for innovation, improvement, or replication. Using state-of-the-art technologies and methodologies, we meticulously analyze and deconstruct components, structures, or processes to understand their functionality, materials, and design principles. Key Features: 1. Comprehensive Analysis: With a keen eye for detail and engineering expertise, we conduct thorough analysis and documentation of existing products or systems. This includes examining components, materials, and design intricacies to uncover hidden insights. 2. Precision Documentation: We utilize advanced tools and techniques to create precise CAD models, schematics, or prototypes based on our findings. This enables us to accurately replicate or enhance existing designs for various purposes. 3. Innovation and Improvement: Whether it's for product enhancement, troubleshooting, or competitive analysis, our reverse engineering solutions empower businesses to drive innovation and stay ahead in today's dynamic market. By understanding the inner workings of existing products, we provide opportunities for improvement and differentiation. 4. Collaborative Partnership: Partner with us to unravel complexities, optimize performance, and drive innovation in your projects. We work closely with clients to understand their specific needs and goals, delivering customized solutions that meet and exceed expectations. With our reverse engineering expertise, businesses can gain valuable insights, optimize performance, and drive innovation in their projects. Let us help you unlock the full potential of your products or systems.

Looking for Product Prototyping Services Providers

Product Reverse Engineering Services

Get Price Quote

Unlock the secrets of your competitor's products with our expert Product Reverse Engineering Services. We meticulously deconstruct and analyze products to reveal their materials, components, and manufacturing processes. This valuable insight allows you to innovate and improve upon existing designs, optimize production costs, and enhance product performance. Whether you're looking to replicate, innovate, or enhance, our team provides detailed reports and recommendations tailored to your needs. Partner with us to gain a competitive edge and drive your business forward with superior products.

Engineering Services for New Plastic Product Development

Get Price Quote

Polymergenix also offers consulting services in the areas of Product Innovation, Value Engineering, Preliminary Design Studies, Process Automation, Technology Integration/Transfer, Application Development, etc. Our team has over 22 years of experience into the Engineering Services domain which differentiate us from other reprocessors & compounders.

Marine Loss Control Engineering Services

30,000 - 300,000 Per visit

01 Visit (MOQ)

product rapid prototyping service

15,000 Per Service

Our Product Rapid Prototyping Service accelerates product development by swiftly translating digital designs into physical prototypes. Using cutting-edge technology and diverse manufacturing methods, we create precise and functional prototypes for validation, testing, and visualization purposes. From concept to tangible model, our service enables quick iterations and customization, fostering innovation and reducing time-to-market. We specialize in producing high-quality prototypes for various industries, aiding in design verification, enhancing product functionality, and facilitating efficient product development processes.

Prototype Designing

Get Price Quote

We are engaged in offering unmatched Prototype Designing to the clients all over India and Worldwide. Through our Prototype Designing services, we are capable of making millions of identical shapes.Within our Prototype Designing services, we are able to meet demands of several manufacturing companies for making prototype assemblies. With the help of CAD/ CAM facilities, we are able to offer Prototype Designing services at reasonable rates. Designs made through our Prototype Designing services can be easily implemented within hours through the machines files that are formulated on our software.

Engineering Models

Get Price Quote

We offer the best quality Engineering Models for Civil, Mechanical & Architectural Engineering. Engineering Models, manufactured and supplied by us, is made using reasoned pine wood & play wood. The surface of Engineering Models is well painted. We also provide fittings of iron, aluminium and brass as per the requirement. Engineering Models are required for basic understanding of the students of engineering. We have a wide range of Engineering Models of buildings, bridges, culverts, railway, dams, irrigation, public health, etc.

Plastic Injection Moulding Services

Get Price Quote

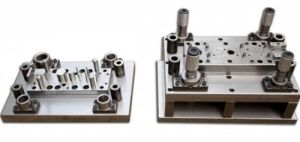

Process Overview – Injection molding is a manufacturing process in which molten plastic is injected into a mold which is made up of steel or aluminum. Principally it is like a die casting process used for making metal parts. The semi-molten plastic is injected into a feeding system and traversed to the mold before passing through feed, transition, and metering section. The Injection molding process cycle consist of six main stages : Closing of mold – When the mold is closed the injection molding cycle timer begins Injection - Heated plastic is injected into the mould. As the melt enters the mould, the displaced air escapes through vents in the injection pins and along the parting line. A good runner, gate and vent design are important to ensure the mould is properly filled. Cooling - Once the mould is filled the part is allowed to cool for the exact amount of time needed to harden the material. Cooling time is dependent on the type of resin used and the thickness of the part. Plasticizing the resin - While the part cools, the barrel screw retracts and draws new plastic resin into the barrel from the material hopper. The heater bands maintain the needed barrel temperature for the type of resin being used. Ejection - The mould opens, and the ejector rod moves the ejector pins forward. The part falls and is captured in a bin located below the mould. Removing the runner – Runners and gates are removed from the original part. Runners are also ground and recycled to reduce costs and environmental impact. Capabilities Integrated sequential manufacturing process under one roof i.e., Simulation -> Tool designing and manufacturing -> Prototype -> Mass production Tool room equipped with VMC’s and CNC’s for manufacturing of die and molds Prototype to high volume production of up to millions of parts per year based on part configuration Manufacturing of parts wide variety of materials such as ABS, LDPE, HDPE, Nylon, PC etc. Manufacturing of molds for up to 3000 Ton molding machine Provide different type of finish to molded part based on customer requirement CMM inspection for part validation and approval In-house lab tests carried out for raw material verification at production site, certified to international standards Defect analysis of plastic molded parts as per international standards Customer appointed third party inspection and verification allowed Manufacturing facility certified to IATF 16949 and ISO 13485 Quality Management System Implementation of Lean Six Sigma tools for better quality control, process control, part traceability and documentation Industry 4.0 integrated manufacturing facilities Application and Benefits Injection molded parts have vast application in consumer and commercial products which are used by us in our daily lives. Few commonly known parts include : Automotive parts – Dashboards, bumpers, grills Electronic components – Connectors, enclosures, protective sleeving Medical devices – Syringes, valves, dishes Consumer plastics – Mobile covers, bottles, toys Furniture – Seat covers, cushions, chairs Few important benefits of plastic injection molding are : Highly efficient mass production Low production cost Manufacturing of complex and intricate parts Enhanced material strength Flexibility of material and color selection Reduced material wastage

Building Model Maker Services

Get Price Quote

Our Building Model Maker Services provide precise and detailed scale models for architectural, real estate, and construction projects. We specialize in crafting high-quality, custom building models that help visualize design concepts, layouts, and spatial arrangements. Whether for presentations, exhibitions, or client demonstrations, our models bring architectural ideas to life with accuracy and craftsmanship. Using advanced techniques and materials, we deliver realistic models with intricate detailing, ensuring your project is represented effectively. Trust us for exceptional models that enhance your presentations and design communication.

Instrumentation and Control Engineering Service

Get Price Quote

Our Instrumentation and Control Engineering Service provides tailored solutions for precise and efficient system automation. We specialize in designing, installing, and optimizing instrumentation and control systems across various industries. Our expert engineers ensure seamless integration, reliable operation, and enhanced performance through advanced technology and rigorous testing. Whether you need process automation, SCADA systems, or PLC programming, we deliver innovative solutions that optimize your operations. Partner with us for comprehensive instrumentation and control engineering services that meet your specific needs and exceed expectations.

Reverse Engineering and Design services

Get Price Quote

1 Piece (MOQ)

With the sincere efforts of our experienced professionals, we have been able to provide our clients superior quality Reverse Engineering Service. The provided service is rendered using excellent quality inputs. Apart from this, owing to its flawless execution, and promptness, this service is valued by our clients.Other Details: Perfect work On-time completion Quick service Execution in tandem with clients detailed guidelines

Sand Model Set

4,500 Per Piece

01 Set (MOQ)

We are offering sand model set sand model set- containing 300 nos of items.

Collection of Rocks Model

230 - 300 Per Piece

1 Piece (MOQ)

This Collection contains 50 Types of Rocks Specimens of Igneous, Sedimentary & Metamorphic Rocks Types. The Rock Specimens include Andesite, Anthresite, Basalt, Bituminous Coal, Breccia, Chalk Lumps, Chert, Conglomerate, Diatomite, Diorite, Dolerite, Flint, Gabbro, Gniess, Granite Black, Granite Phorphery, Granite Red, Granite White, Khondalite, Kimberlite, Lime Stone Black, Lime Stone Silicious, Lime Stone White, Marble Black, Marble Chocolate, Marble Green, Marble Pink, Marble White, Marble Yellow, Mud Stone, Obesidian Black, Obesidian Green, Pegmatite, Pegmatite Mica, Phylite, Pumic, Quartizite Black, Quartizite Gray, Quartizite Green, Quartizite Pink, Quartizite White, Quartizite Yellow, Rhyolite, Rock Phosphate, Rock Salt, Sand Stone Red, Sand Stone Silicious, Serpentine, Shale, Slate etc.

Wooden Object Drawing Models

Get Price Quote

100 Set (MOQ)

We manufacture various engineering models for display and training students about Object drawing Models Dissected(wooden), drawing board stand, Rectangular prism, Rectangular pyramid, triangular prism, triangular pyramid, square prism, square pyramid, Pentagonal prism, pentagonal pyramid, Hexagonal Prism, hexagonal pyramid, Ocatgonal prism, Octagonal pyramid, decagonal prism, Decagonal pyramid, Cube 20x20x20 cm, Cone , Cone cut sections, Sphere 15 cm. Cylinder Cone in 5 parts Object drawing Models non dissected(wooden), Rectangular prism, Rectangular pyramid, triangular prism, triangular pyramid, square prism, square pyramid, Pentagonal prism, pentagonal pyramid, Hexagonal Prism, hexagonal pyramid, Ocatgonal prism, Octagonal pyramid, decagonal prism, Decagonal pyramid, Cube 20x20x20 cm, skeleton cube, cone , sphere 15 cm, Half sphere, cylinder, semi cylinder, Quarter cYlinder, tetrahedron, octahedron, circle, Dodecahdron, icosahedron Other Models(wooden) Isometric wooden projection model(Set of 10) Different type of joints(set of 9) interpretation of solids(set of 5) Geometrical instrument box wooden H.P horizontal plane /V.P vertical plane (plastic), octant

Plastic Injection Moulding Services

Get Price Quote

Plastic Injection Moulding is a precise manufacturing process used to produce high-quality plastic parts and components for various industries, including automotive, electronics, and consumer goods. This method involves injecting molten plastic into a custom-designed mold to create detailed, durable parts with minimal waste. It supports a wide range of materials and offers high repeatability, making it ideal for mass production. Plastic injection molding services typically include mold design, prototyping, and production. With quick cycle times and high accuracy, these services provide cost-effective solutions for companies seeking consistent and complex plastic parts at scale.

Gear Models

5,000 Per piece

Our organization has gained name and fame in the field of offering Gear Model to the clients. There is a unique and diverse range of these gear modulation available with our organization. These are available in excellent technical specifications and are renowned for their hassle free performance for long period of time. In addition to this, following gears are available at legitimate prices to the clients. Spur Gear Bevel Gear Helical Gear Worm Gear Compound Gear Differential Gear

Reverse Engineering Services

500 - 5,000 Per no

1 no (MOQ)

3D Scanning, Reverse Engineering Services Creative Tools has rich experience of 3D Scanning, Reverse Engg, Class A Surfacing, Mold Flow, 3D Printing Services.

Orbit Tellurium Model

Get Price Quote

1 Piece(s) (MOQ)

We are offering orbit tellurium model. Harsaw orbit tellurium model is used for demonstration of respective positions and the motions of the earth, moon, and venus around the sun. Rotation of the handle makes the earth to move around the sun, while revolving on its own axis, the moon moves in its orbit around the earth, and venus will follows its path around the sun. It also demonstrates the causes of the seasons, day and night, phases of the moon, and many other related phenomena. The large sphere is the sun, with venus near it, and at the end of 16½ inch arm is the earth with the moon near it. A 220v lamp inside the sun globe projects a beam of light directly on the earth for a clearer visualization of the change of seasons on the earth and to illustrate eclipses.

Architectural Models making services

50,000 - 100,000 Per Bag

Shree Creators Model Making Company offers a wide range of model making services, including architectural model making, industrial model making, marine model making, and engineering model making. Our team of skilled and experienced model makers use the latest techniques and technology to create models that are not only accurate and detailed, but also visually appealing.

injection mould design services

Get Price Quote

we are offering injection mould design services.

Two Stroke Petrol Engine Model

Get Price Quote

Represents internal structure and operating principles of an air-cooled two-stroke engine. All parts in aluminium alloy. Ignition is shown by means of a miniature bulb. Carburetter and fuel supply also sectioned. Mounted on metal base.

Mechanical Engineering Design Development Services

Get Price Quote

undefined undefined (MOQ)

Reverse Engineering Services

Get Price Quote

Tips provide reverse engineering of pcb services. 1. Reverse engineering means reverse process of pcb. 2. Customer provide hardware pcb. 3. Tips will generate gerber-274x data from sample pcb. 4. Tips provide a complete output of gerber-274x data. nc drill data. drill drawing.

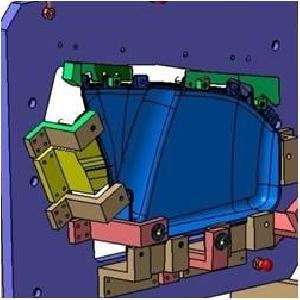

BIW Die & Mould Designing Services

Get Price Quote

Get in touch with us, if you are in search of a reliable name providing BIW die & mould designing services. Parametrik Engineering Pvt. Ltd. is a Pune (Maharashtra, India) based company, known for providing precision-engineered solutions for all sorts of die and moulds. We have a team of professionals, who work together and provide dependable solutions in concern with clients’ requirements and elevated service norms. Our service charges are reasonable. We are specialized in : BIW Interiors and Exteriors Plastic Interiors and Trims Sheet Metal Parts Seating System Design Plastics Components Casting and Forgings

Plastic Injection Mold Designing Services

Get Price Quote

Situated in Shiva Nagar Colony Nagaram, Hyderabad, Telangana (India), Shidha Technologies is involved in providing superior class plastic injection mold designing services to the clients. We have hired a team of adroit plastic injection mold designing experts, who are proficient in melting the solid plastic resin pellets, injecting them into a mold and cooling them back to a solid-state. These experts make use of the most advanced tools & machines to render these services.

Diesel Engine Model

Get Price Quote

10 Piece(s) (MOQ)

Diesel Engine Model is a model of two stroke water cooled diesel engine made in ast alloy metal. Ignition simulated by means of a miniature bulb. Fuel supply is also sectioned. With hand crank proved for manual operation depicting cam operated inlet and exhaust valves. Features of our Model Diesel Fuel Engine: Mounted on metal base with printed diagram and key Mounted on plastic base Today, we have carved a niche as one of the key 3D Diesel Engine Model Exporters from Ambala Cantt.

Diesel Engine Model

Get Price Quote

Scale Models

Get Price Quote

Architectural 3D Models offer robust, colourful and detailed replicas of your 2D architectural plan. We offer a wide range of 3D printed architectural model making services in India using 3D printing to create beautiful models. Our outstanding scalable physical 3D printed models using 3D systems FULL COLORJET PRINTERS, which can provide you the competitive edge to market your products. This 3D printed models can be used at Presentation, Sales office, Conferences, Reception and lobbies.

Reverse Engineering Services

Get Price Quote

Nikita CAD/ CAM Solutions is a New Delhi, India based company, involved in providing reverse engineering services to the clients since 2004. We are providing services for components like plastics, aluminium, sheet metal, rubber, brass, die casting, etc. or as per clients’ requirements. We make use of freeform image ware and I-DEAS software for completing the undertaken task. The assigned task is executed by our industrious professionals. Over the years, we have acquired a remarkable space in this sphere. Contact us for availing our services at economical rates. Details : Plastics Rubber Brass Aluminum Sheet Metal Die casting