WRAPTOR DUCTILITY TESTING UNIT

Sandvik's Wraptor ductility testing unit enables more accurate prediction of the retirement point of a slickline. This can lead to considerable cost savings through the reduced risk of unplanned production stops and the loss of valuable production equipment

...more

Wire Drawing Dies

Sandvik offers an extensive product portfolio for wire drawing solutions. Every stage in the manufacture of cemented carbide components – from powder production to finishing – is crucial for optimum performance. Sandvik employs a methodical process to yield consistent results – every time. Commitment to the wire draw industry and our technical expertise provide a powerful package. We are capable of satisfying your wire drawing needs with production units strategically located around the world and the capacity to support large volumes.

...more

Metal Wires

Sandvik is a leading manufacturer of wire in a wide range of materials including stainless steels and nickel alloys. With our extensive application knowledge we have the expertise to recommend the optimum wire for any wire application, resulting in enhanced end-product performance.

Material : Metal

Certification : ISI Certified

Usage : Construction, Fence Mesh

Grade Standard : AISI, ASTM

Color : Grey

...more

Wheeled Units

Maximising productivity, minimizing investment. Our wheel-mounted semi-mobile crushing and screening units are durable and give outstanding productivity. Designed for flexibility; many combine primary and secondary crushing as well as screening in a single unit. A full production system on one chassis. We have designed all units in the wheeled range to meet the same high standard as our tracked equipment, operating at maximum efficiency and minimizing environmental impact. Our wheeled crusher units are designed with customer's requirements in mind, while ensuring that all units are user-friendly, easy to operate, highly efficient and offer optimum productivity.

...more

Wheeled Crushing Units

Maximising productivity, minimizing investment. Our wheel-mounted semi-mobile crushing and screening units are durable and give outstanding productivity. Designed for flexibility; many combine primary and secondary crushing as well as screening in a single unit. A full production system on one chassis. We have designed all units in the wheeled range to meet the same high standard as our tracked equipment, operating at maximum efficiency and minimizing environmental impact. Our wheeled crusher units are designed with customer's requirements in mind, while ensuring that all units are user-friendly, easy to operate, highly efficient and offer optimum productivity

...more

WELD FINISHING

Sandvik provides chemical products for improving the surface finish and corrosion resistance of welds. These include root flux for root protection during welding, pickling paste for post weld treatment and neutralization paste for neutralizing pickling residues to pH value 7-10, facilitating rapid precipitation of metallics.

...more

Wedge Crested Inserts

This type of insert is predominantly used in the outer or gauge row on roller cone drilling bits. The wedge design increases the insert strength.

...more

Seal Ring Bushing Material

It is essential that wear parts have extremely high resistance to corrosion due to the nature of their environment. Sandvik engineers custom parts using cemented carbide, which stand the test of harsh elements.

...more

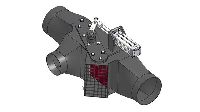

VR SERIES - ROTAPORT CONE SPLITTER

Our Rotaport Cone Splitter gives you accurate, trouble-free sampling results from production, grade control, and exploration mineral drilling. By rotating the cutting ports below the sampling cone, sample quality can be greatly improved when material flow bias is present. ADVANTAGES Multiple samples can be taken simultaneously – saving you time View of cutter while rotating parts are fully guarded, which saves maintenance Sample bags are enclosed during operation, protecting from outside elements during sampling—ensuring quality Safety interlocked with user-friendly

...more

VR SERIES - RC INVOLUTION CYCLONE

Our RC Involution Cyclone combines inlet velocity reduction with standard ceramic liners to minimize wear, while increasing efficiency for sampling by intensifying centrifugal effect. This helps you with increasing rig volumes and a need to drill faster, deeper holes.

...more

VR SERIES - INTERVAL DROPBOX

Our interval dropbox provides a seal from the harsh whirlwind created in the cyclone when material enters the splitter. It has greater capacity than other equivalent drill-sampling products without increasing your system height. Designed for wet and dry drill sampling. ADVANTAGES Comes equipped with PLC-pneumatic control box with a remote control, to give you easy command while ensuring accuracy Patented floating seal design allows doors to self-adjust to seal even after considerable wear has occurred Increased holding capacity (60-liter 15 gal) helps you by sharply...

...more

VR SERIES - EMISSION FILTER

Our sampling equipment emission filter prevents dust emissions from entering the atmosphere, during the drilling process, which could obscure vision and make it unhealthy to breathe. It incorporates an exhaust fan that is designed to overcome sampling system pressure drops.

...more

VR SERIES - EF DIVERTER VALVE

Our EF Diverter Valve prevents moisture from entering the emission filter during wet drilling. It opens to divert moist drilling air out to the open air, thus protecting your emission filter bag. Simultaneously, it opens at the rear to keep the exhaust fan off while wet drilling. ADVANTAGES Protects the emission filter bag during wet drilling, saving you cost and ensuring productivity Features specially formulated rubber lined double acting diverter flap, which assures continual flow Protects the sampling system from suction (vacuum) damage and "blowback" cleaning, reducing your downtime and costly maintenance

...more

VM SERIES -ROTATING CONE SPLITTER

Our rotating cone splitter can operate in any drilling environment, provide vastly more accurate sampling results than has ever seen before, and can increase or reduce your split percentages by the simple change of cutter blades. ADVANTAGES Samples accurately, even if not completely level Quick and easy design for loading and unloading Provides both sample and duplicate sample Increases or reduces split percentages by the simple change of cutter blade ..

...more

VM SERIES Cyclones Sampling Equipment

Our VM series cyclones sampling equipment are designed for grade control and mineral exploration. We make them easy for you to use, lightweight, and safe to handle. They feature a hinged, gas strut lid for easy access. ADVANTAGES Cyclones feature a simple design with fewer wear parts, making them easy for you to maintain Quality-built, heavy gauge design, ensures long life and saves you money We simplify things by giving you the option to bag collect samples or collect at the bolted-on flanged product outlet

...more

VM SERIES - BLAST HOLE SPLITTER

Our blast hole splitters come with an adapter that allows fitment onto its production rigs and can also be adapted for other drill rigs on the market. ADVANTAGES Quality-built, heavy gauge design provides the durability you demand Gravity feed means that you have minimal maintenance Easy access for cleaning riffles Clean, mild steel construction ensures quality sampling Super simple: one sample port, one waste port

...more

VM SERIES - ADJUSTABLE CONE SPLITTER

Our adjustable cone splitter operates in any drilling environment, provides you with vastly more accurate sampling results, and can adjust your split percentages by simply changing cutter blades. Designed for your grade control and exploration applications.

...more

Versimax Nozzles

The high abrasion resistance, corrosion resistance, and flexibility in manufacturing complex shapes make Versimax an ideal choice for demanding nozzle applications. Nozzle lifetime, and cost per unit produced, can be increased substantially by incorporating Versimax diamond composite in the high wear areas in tungsten carbide, ceramic, or other wear resistant nozzles. The examples below illustrate the potential for overall cost savings using Versimax in highly erosive applications.

...more

Versimax Diamond Composite Wire Dies

Our Versimax� product is a ceramic-bonded diamond composite with exceptional wear resistance, mechanical strength and high temperature performance. Versimax die blanks are free-standing cylinders, which are electrically conductive and can be easily pierced using EDM technology. Versimax die blanks are thermally stable up to 1,200°C.

...more

Versimax Diamond Composite

Versimax is a silicon carbide bonded diamond composite with superior wear resistance, high strength, and high temperature performance. Versimax has hardness, strength, and toughness approaching that of Co-sintered PCD but provides superior thermal stability. The ceramic bonded composite is impervious to most corrosives. Versimax finds use in nozzles, wire bundling and stranding dies, grinding centers, truing and dressing tools, and a wide variety of other wear parts across many industries. The material is produced as a monolithic solid and does not come attached to a cemented carbide substrate. If desired, it can be attached to cemented carbide using furnace brazing methods and active brazing alloys, achieving shear strengths of 250 to 350MPa, at brazing temperatures between 650 and 925C. Versimax is available as large as 35mm diameter and 38mm overall thickness. Thermal stability Versimax is a composite composed of 80% diamond bonded by a continuous matrix of ceramic silicon carbide. Since Versimax does not contain the interstitial Co catalyst present in sintered PCD, Co-assisted thermal degradation due to Co thermal expansion and graphitization does not occur, and Versimax is stable up to temperatures of 1200C. The thermal stability of Versimax was demonstrated by heating the material in an inert atmosphere to 1200C and held for 1 hour. The transverse rupture strength was measured after cooling to room temperature. Unlike PCD which would crack over 700C, Versimax retained 90% of its strength after high temperature exposure.

...more

Versimax Diamond Composite

Versimax is a silicon carbide bonded diamond composite with superior wear resistance, high strength, and high temperature performance. Versimax has hardness, strength, and toughness approaching that of Co-sintered PCD but provides superior thermal stability. The ceramic bonded composite is impervious to most corrosives. Versimax finds use in nozzles, wire bundling and stranding dies, grinding centers, truing and dressing tools, and a wide variety of other wear parts across many industries. The material is produced as a monolithic solid and does not come attached to a cemented carbide substrate. If desired, it can be attached to cemented carbide using furnace brazing methods and active brazing alloys, achieving shear strengths of 250 to 350MPa, at brazing temperatures between 650 and 925C. Versimax is available as large as 35mm diameter and 38mm overall thickness. Thermal stability Versimax is a composite composed of 80% diamond bonded by a continuous matrix of ceramic silicon carbide. Since Versimax does not contain the interstitial Co catalyst present in sintered PCD, Co-assisted thermal degradation due to Co thermal expansion and graphitization does not occur, and Versimax is stable up to temperatures of 1200C. The thermal stability of Versimax was demonstrated by heating the material in an inert atmosphere to 1200C and held for 1 hour. The transverse rupture strength was measured after cooling to room temperature. Unlike PCD which would crack over 700C, Versimax retained 90% of its strength after high temperature exposure. Tool Fabrication

...more

UV320 Wheeled Unit

Our UV320 is an integrated Vertical Shaft Impact crusher and three-way split screener on a wheeled chassis. This unit has been designed for the production of premium shaped aggregates for your concrete and asphalt applications. We have combined our state of the art CV117 crusher and our three-way split screening technology for maximum mobility and flexibility of operation. This unit is highly productive and produces the highest quality materials. There are three models available to ensure we meet your application needs:

Weight : 46,300 kg / 101,800 lbs

...more

UV311 Wheeled Unit

The CS430 Cone crusher is characterized by the large intake capability and the high capacity in relation to size. The large intake capability, adjustable throw and high motor power give this crusher a unique possibility to handle a wide range of secondary applications. Features and benefits Excellent in secondary applications due to the large feed opening Possibility to use as a primary crushing stage depending on feed size requirement Adjustable throw give the possibility to fine tune the performance to match the desired need Full control of the process Easy to maintain Extremely reliable

Capacity : 90 - 345 tph

...more

UV210 Wheeled Unit

Our UV210 is a tertiary crushing unit fully assembled on a single trailer frame. We have designed this unit to be highly productive to meet your needs. It features a three deck vibrating screen and VSI crusher. Our VSI crushers present you with premier quality vertical shaft impact crusher technology. We have included many new and advanced design features enabling you to achieve maximum efficiency and reliability in your operation.

Power : 200 kW / 268 hp

...moreBe first to Rate

Rate This