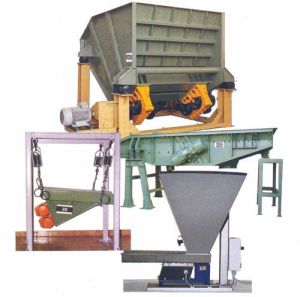

Vibrating Screen

The decision to select a particular vibrating screen is critical. It impacts the operating life, efficiency of screening, maintenance requirement, inventory cost, environmental factors and of course investment. A wrong choice could lead to bottlenecks in material flow, preventing the plant from working to its capacity. Electro Zavod screens are rugged and designed for a long life. Due to the vast experience of JOST and the wide choice of vibratory drives available, Electro Zavod selects and delivers the most efficient and economical screen for each individual application. Selection of the correct drive is very important for screening efficiency and highest possible output especially for prolonged usage over the life of the machine. Electro Zavod has the complete range of vibrating drives which enables us to make the optimum selection. Screening performance is affected by various characteristics of the feed material including particle shape, bulk density, flow-ability and surface moisture. Most important perhaps, is the particle size distribution of the feed. It is essential to choose the correct screening motion and configuration for performance and durability.

...more

Vibrating Feeder

ontrolled mechanical vibrations are used in the transfer of bulk material in the form of solid, powder or granule form. Controlled mechanical vibrations can be produced by setting predetermined frequency and amplitude.

...more

Spring Driven Cable Reeling Drum

Spring Driven Cable Reeling Drums are driven by special helical springs. Generally springs have a limited life. Due to continuous winding and unwinding operation normal fatigue stes in. If the best material is used, will show signs of fatigue after approx 40,000 to 50,000 movements. This metal fatigue can lead to breakage of the springs. Any small oscillation of the spring to be considered as one movement. There are two types of spring drums. In one type the springs are mounted on the drum shaft and tensioning is achieved by rotation of the drum body. In the other type, the springs are accommodated in a separate i.e.a spring motor. The spring motor facilitates easy spring replacement, without disconnecting/removing the trailing cable Cable Reeling Drum with Spring Drive The Spring acts as the drive force. Due to the limited torque available from the spring, the size and length of cable that can be wound is limited for Spring Drums. The efficiency of the drive mainly depends upon the spring life, and the life of the spring depends upon the number of operations i.e. the working cycle. The application of spring drum is limited to electro-magnets, machine tools etc. Since the efficiency and reliability of the drum depends on the quality of the spring, great care is taken in the selection and manufacture of the spring.

...more

Slipring Assembly

Slipring Assemblies are used for carrying electrical current from a stationary part to a rotating part of an equipment such as Rotary Crane, Rotary Reclaimer, Cable Reeling Drum, Excavator,Circular blenders, Rotatory Kilns etc. The sliprings or the brush holders can be mounted either on the fixed or the rotating part of the machinery as per machine design. Rings of various amperages can be combined to form Slipring Assemblies and a combination of Power, Control and Communication can be offered. Our design range caters to the following requirements - Slipring Current rating 15 Amps. - 600 Amps. Number of Sliprings upto 50 Nos. with a combination of control, power and communication. Voltage rating 220V, 415V, 3300V, 6600V and 11000V Sliprings are made of Cast Brass or Copper Brushes - Copper Carbon Insulator - Epoxy Resin Applications of Slipring Assemblies – Earth Moving Equipments Rotary Cranes Jib Cranes Excavators Reclaimers Circular Blenders Cable Reeling Drums Clarifoculators Benefits - Twisting of cable avoided Fatigue of cable avoided Continuous conductivity ensured Highlights – Compact Easy installation Rugges in design Weather proof Vermin proof

...more

Reeling Drum

Cable Reeling Drums are used for automatic reeling and unreeling of flexible trailing cables for current-consuming mobile machines, whose travel is mostly track bound. The spring acts as the drive force. The spring drum is used for small sizes and lengths of cable. Due to the limited torque available from the spring, the size and length of cable that can be wound is limited. The life of the spring depends upon the number of operations i.e. the working cycle. The application of spring drum is limited to electro-magnets, machine tools, etc. Since the efficiency and reliability of the drum depends on the quality of the spring, great care should be taken in the selection and manufacture of the spring.

...more

Pulse Metal Detector

Electro Zavod Metal Detectors detect the presence of metals-both magnetic and non-magnetic in moving bulk material. Tramp Metal affects many Industries, and presents Quality Control problems or a Hazard to processing equipments i.e. Crushers, Ball Mills, Conveyor Belts, etc. Electro Zavod Metal Detectors meet the requirements of a wide spectrum of industries like Iron Ore, Metallic Ore, Cement, Coal, etc. Electro Zavod Metal Detectors with rugged design and continuous heavy- duty usage, are field proven. Electro Zavod’s R & D and continuous innovations ensure the performance and reliability of Metal Detectors. Principle of Operation Electro Zavod Pulse Metal Detectors operate on the principle of Eddy Current induced imbalance in a set of mutually balanced coils. A frequency of 20 KHz to 100 KHz is used to generate an electromagnetic field in the aperture area. The system automatically maintains a high degree of balance which is distributed by the metal passing through the aperture resulting in a signal, which is amplified to operate an audio visual alarm and interlock or reject mechanism system. Electro Zavod Pulse Metal Detector The Electro Zavod Pulse Metal Detectors works well with magnetic and conductive ores. No other system can work effectively when a tramp metal is to be detected in the presence of magnetic and conductive ores. The Electro Zavod Pulse Metal Detector detects 25mm MS sphere/cube and 25mm Al sphere/cube. Detects ferrous and non-ferrous metal including manganese steel and stainless steel. Distinguishes between stationary and moving metals. Automatic sensitivity for temperature variation and static metal. Adjustable sensitivity. Completely solid state using latest technology, ruggedly built to give years of trouble - free operation. Easy installation: Search Coil can be installed around an endless belt. Can take supply voltage variation of 1- 15%. Extremely low power consumption. Suitable for ambient temperature up to 55°C and humidity 100%. Audio-Visual Alarm to draw the attention of the operator. Potential - free change over contact for interlocking as per customers requirements. Reliable Sand Bag Marker and External Hooter can be coupled to the system.

...more

Permanent Magnetic Separator

Belt type Magnetic Separator Magentic Drum Separtor Magnetic Pulley Product Enquiry

...more

Magnetic Separator

Electro Zavod Overband Magnetic Separators are available in two basic designs : In Line models are suspended along the main conveyor belt. The separator is mounted at an angle as shown for better performance. The belt of the separator travels in the same direction as the main process conveyor with a speed which is equal or greater than the main burden speed. The tramp is discharged away from the conveyor belt in the direction of travel. Transverse Separators are suspended at right angles to the main conveyor. It can be installed anywhere along the conveyor line. The tramp is discharged at right angles away from the conveyor. Electro Zavod Suspended Magnets These operate most efficiently when they are placed at an angle over the conveyor head or over the discharge point of a vibratory feeder. In such cases, the magnets can remove more tramp from deeper burdens even at higher conveyor speeds since the burden loosens up and fans out. In cases where the magnet cannot be installed at an angle over the discharge point, it may be suspended parallel to and above the conveyor belt. Selection of the proper magnetic separator for any application requires very careful evaluation of all operating conditions and separation objectives. The magnetic field configuration of any magnetic separator, regardless of type, should profile the conveyor belt for maximum tramp removal. To help proper selection, to enable us to recommend the most efficient and economical magnet, the following information is required - Belt width Belt Speed Belt incline Troughing idler angle Burden depth Capacity in TPH Material size & density Minimum & maximum tramp metal size Desired location of magnet Head pulley material & diameter Type of separator Suspended In line Transverse

...more

Linear Motion Screen

Circular Motion Screens are operated either by a mechanical exciter or two unbalance motors. In both cases rotation in opposite directions creates linear vibration. Linear motion screens are very high performance machines, in terms of capacity and efficiency. They have a low inclination which varies between 0 degree and 15 degree. The drive is a combination of high amplitude and low frequency of vibration.

...more

Lifting Magnet

low Dead Weight Large Lifting Capacity Unequalled rates of lifting capacities to magnet weight Relatively low power consumption Stainless steel base plate - weather proof, right, less complex Easily exchangeable wear part for the central poles Lower total cost of ownership - considering purchase, running and maintenance costs Electro Zavod makes the following lifting Magnets : Rectangular Lifting Magnets : 18" Series/ Copper Wound 22OV DC 18" Series/ Aluminum Wound 22OV DC 24" Series/ Aluminum Wound 22OV DC Circular Lifting Magnets : Standard Type Heavy Duty Type Heavy Duty Deep Field Type Consultation & Design : Electro Zavod can servey your requirements and help to select the right equipment. If you require non-standard equipment, we can manufacture specific to your needs.We can make Old magnets New, for example: Rewinding with Aluminium instead of Copper.make Old magnetsw, for example:ewinding with Aluminium instead of Copper.We can make Old magnets New, for example: Rewinding with Aluminium instead of Copper.

...more

Inline Magnetic Separator

Electro Magnetic SeparatorsSuspension Magnets are designed specifically for the extraction of continuousoccasional tramp iron from material being carried by conveyor belts, vibratory feeders or gravity chutes. The Electro magnets employ a high permeability magnetic path using tripolar design. They are D. C. operated rectangular magnets. To remove tramp iron materials for protection of expensive equipment in the downstream process.For purification of conveyed material, for reclaiming and salvaging valuable ferrous scraps.

...more

Conveyor Magnets

These operate most efficiently when they are placed at an angle over the conveyor head or over the discharge point of a vibratory feeder. In such cases, the magnets can remove more tramp from deeper burdens even at higher conveyor speeds since the burden loosens up and fans out. In cases where the magnet cannot be installed at an angle over the discharge point, it may be suspended parallel to and above the conveyor belt. Selection of the proper magnetic separator for any application requires very careful evaluation of all operating conditions and separation objectives. The magnetic field configuration of any magnetic separator, regardless of type, should profile the conveyor belt for maximum tramp removal.

...more

Circular Lifting Magnets

low Dead Weight, Large Lifting Capacity, Unequalled rates of lifting capacities to magnet weight, Relatively low power consumption, Stainless steel base plate - weather proof, right, less complex, Easily exchangeable wear part for the central pole, Lower total cost of ownership - considering purchase, running and maintenance costs.

...more

cable reeling drum

Cable Reeling Drums are used for automatic reeling and unreeling of flexible trailing cables for current-consuming mobile machines, whose travel is mostly track bound. There are mainly three modes of drive for the drums:- Cable Reeling Drum with Spring drive The spring acts as the drive force. The spring drum is used for small sizes and lengths of cable. Due to the limited torque available from the spring, the size and length of cable that can be wound is limited. The life of the spring depends upon the number of operations i.e. the working cycle. The application of spring drum is limited to electro-magnets, machine tools, etc. Since the efficiency and reliability of the drum depends on the quality of the spring, great care should be taken in the selection and manufacture of the spring. Cable Reeling Drum with counter weight drive The counter weight acts as the drive force and is suitable for cable sizes upto 4 x 95 mm sq. and travel length upto a maximum of 100 metres. The length of cable is limited by the height the counter weight has to traverse. Cable Reeling Drum with stall torque motor drive The drum is driven by a specially designed "Stall Torque Motor". The motor provides the necessary torque for the rotation of the drum and has proven to be the most reliable drive for the cable reeling drum. Motorised cable reeling drums can handle almost all sizes and lengths of cable. The stall torque motor is a brake motor capable of producing a strong torque while remaining close to or exactly at zero speed i.e. rotor in locked condition, without overheating. While the reel is unwinding the rotor is moved against its natural direction of rotation, without being electrically reversed. This is the unique feature of the stall torque motor which makes it extremely suitable for reeling and unreeling application. This motor has a conical rotor and a built-in-brake. The stall torque motor is available in squirrel cage as well as slipring construction. The two types used are : Squirrel cage motor – 12 poles operating range. - 500 to + 500 rpm Slipring motor - 4 poles operating range. -600 to +1500 rpm The output torque can be reduced in the slipring motor by increasing the rotor resistance.

...moreBe first to Rate

Rate ThisOpening Hours