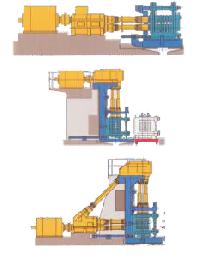

Housingless Stands

Stand-mounting variants: Horizontal mill stands Multigroove rolls Grooves changed by shifting the stand Stands changed by shop crane Stand-mounting variants: Vertical mill stands Top-driven rolls Multigrooves rolls Stands changed on stand changing rig Use of concrete supports Stand-mounting variants: HorizontalVertical mill stands Multigroove rolls Grooves changed by shifting the stand Stands changed on stand changing rig Use of concrete support

...more

High Speed Laying Head

Project Engineering • Supply • Services Characteristics of advanced wire rod mills Production speeds up to 120 ms Utilization factor up to 90 % and more Yield of material over 96 % Good tolerances and minimum surface scratching to achieve best prices in the markets Temperature control system throughout the mill to achieve repeatable and uniform material properties : Rolling within closed temperature ranges meeting the particular material demands Low temperature rolling Controlled cooling process used as in-line heat treatment or for “pre-adjustment” of material properties Low labour cost due to high degree of automation Extensive program system for both the rolling process and subsequent rod treatment Developed and improved continuously, including the experience and expertise gained from many Rolling mills delivered by Rana Udyog An effective tool to save costs in downstream processes and achieve an optimal product structure and specific Physical properties Intermediate cooling upstream the rod mill block Maintain the desired temperature field by regulating the water pressure Temperature controlled rolling possible Improved grain size(fine) of rolled material Quick-acting valves for higher speeds and small-diameter rod to shut off the water flow while the rod head end enters the cooling pipes. Cooling line also suitable for other products High strength values: • Yield point : 500 Nmm2 • Tensile strength: 560 Nmm2 • Elongation percentage grade: 12% Other data: • Final rolling temperature: 950-1050°C • Equalizing temperature at laying head: 650°C • Water pressure, max: 1.6 Mpa • Max product speed, approx: 80 ms

...more

Crank Shears

The design of knife carrier will be adopted to the required application, e.g.: One knife track, one knife: cropping, dividing (e.g. cooling bed lengths) Low temperature rolling One knife track, two knives: cropping; emergency cutting One knife track, various knives short emergency lengths Two knife tracks, with additional switch: 1st track one knife: cropping, dividing 2nd track various knives: short emergency lengths Shear start is initiated by pulse generator (billet head end) Cut according to chosen crop length After cutting, the shear is stopped again Crop end diverted into scrap disposal system

...more

Crank Lever Shears

Crank lever shears working as start-stop-shears and adopt the crank-and-rocker principle of operation. Whilst performing the shearing operation the knives are almost perpendicular to the stock to be cut. This shears are suited to crop, cut sections and cooling bed lengths as well as for emergency cutting.

...more

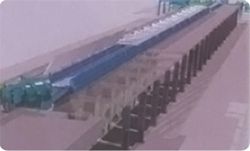

Automatic Rake Type Cooling

Valued Clients: Automatic Cooling Bed ISI Bar, Khopoli , Maharashtra Gulf Steel, Abu Dhabi Himal Iron, Kathmandu, Nepal Confab, Colombo Tisco, Jamshedpur For Their 600,000 New Bar Mill (morgan). Peekay Steel, Calicut Cisco, Capetown- South Africa Tulsyan Nec, Chennai Vikash Metal & Power Ltd, Purulia, West Bengal Ankit Metal & Power Ltd, Bankura, West Bengal Bma Stainless Limited, Assansol, West Bengal Nalwa Sponge Limited (jindal), Raigadh Suryadev Alloys Ltd- Chennai Brahmaputra Rolling Mills, Guwahati Shree Trichy Sumathai Steel Rolling Mills Pvt Ltd, Coimbatore JSW (morgan) Abuja Steel Mills Limited, Nigeria BDG Metal & Power Ltd, Kolkata Purulia Metal Casting Pvt Ltd Rashmi Metaliks Ltd, Kolkata Shree Sanyeeji Ispat Ltd Modern India Steel Rolling Mills Pvt Ltd, Kolkata Kamachi Sponge & Power Corporation Ltd HRG Alloys And Steels Pvt Ltd, Bangalore Nav Durga Fuel Pvt Ltd, Raigarh Steel Rolling Mills Ltd, Kampala, Uganda Salam Casting, Bangladesh

...more

Automatic Cooling Bed

Cold Shears

Steel Pinch Roller

Housingless Mill Stand

Rod Mill Block

wire rod mill

Flying Shears

Mechanical Shears

bar mills

Starting Stock Billets 160 x 160 x 12,000 mm 130 x 130 x 12,000 mm Furnace Group Charging grate, Hot charging, Elevator, Induction online heater Finished product Rebar 8 three-strand slit TMT Rebar 10 two-strand slit TMT Rebar 12-40 mm TMT Flats, angles and channels are possible too Sub-bundles 100-400 kg Master bundles 1 MT-3 MT Furnace Capacity 80 MTh Main train Single-strand HV arrangement, two strands are HV type Roughing train : 4 off Model 600, 2 off Model 440, Free outletafter stand # 2 Intermediate train : 4 off Model 440, 4 off Model 340 Finishing train : 6 x Model 340 Associated shears Loopers : 8 off vertical, 6 off Single strand, 2 off multi strand Capacity 400,000 MTy Cooling bed group Water quenching line, Thermex® Cooling bed shear Cooling bed 66 x 10 m

...more

Structural Steel Mill

Starting stock Blooms 180 x 180 x 8,000 - 12,000 mm 300 x 300 x 8,000 - 12,000 mm Finished product Rebars 28 - 40 mm Rounds 30 - 100 mm dia. Hexagons 50 - 80 mm Flats 8 x 30 - 60 x 150 H-Beams 100 - 180 mm I-Beams 100 - 200 mm T-sections 75 - 140 mm Channels 100 - 200 mm Angles 80 x 80 x - 200 x 200 mm U-type sections for mine timbering 18U, 25U,29U Bundlestack length 6 - 24 m Bundlestack weight 2 - 5 t Furnace capacity 116143 th Annual capacity 700,000 ty Finishing speeds 6 ms Material grades Carbon steels, Alloyed structural steel,Antifriction bearing steel Furnace group: Elevator (for hot charging), charging grate,weighscale, descaler, insulated holding tunnel Mill train: Single strand Roughing train 4 x Model 670, 1 x Model 760(V-H-HV-H) Intermediate train: 2 x Model 760, 4 x Model 670(H-H-H-UR-UR-HV) Finishing train: 5 x Model 670 (UR-HV-UR-HV-FUR) Associated shears Loopers: 4 x vertical Cooling bed group: Water cooling line, pinch roll unit Cooling bed shear Cooling bed 84 x 19 m Short-bar collecting device Continuous finishing shop In-line straightening machine (10 rollers) Hot saws: 1 x stationary, 1 x movable Abrasive cutting machines: 1 x fixed, 1 x movable Piling and stacking facilities (magnet-type) Tying machines: 2 x stationary, 2 x movable Various associated equipment, e.g. stoppers, chain transfers, roller tables etc.

...more

section mill

Starting stock Billets 100 x 100 x 12,000 mm 200 x 200 x 12,000 mm Finished product Rounds 8 - 50 mm dia. and equivalent squares, hexagons and rebars Flats 38 x 5 - 100 x 15 mm Angles (equal legs) 32 x 4 - 70 x 6 mm Angles (unequal legs) 45 x 28 x 3 - 63 x 40 x 8 mm Channels 50 - 80 mm Furnace capacity: up to 200 th Capacity: 1,000,000 ty Finishing speeds: up to 20 ms Material grades: Carbon steels, Alloyed structural steel, Antifriction bearing steel, Spring steel Furnace group: Charging grates (2x), weighscale, descaler,insulated holding tunnel Mill train: Single strand, HV- arrangement, 6 mill stands are the HV-type Roughing train: 2 x Model 670, 4 x Model 440 Intermediate train: 6 x Model 390 Finishing train: 6 x Model 390 Associated shears Loopers: 6 x vertical Cooling bed group: Water cooling line, pinch roll unit Cooling bed shear Cooling bed 102 x 13 m Continuous finishing shop: In-line straightening machine (10 rollers), Flying cold shear Piling and stacking facilities (magnetic-type) Tying machines Various associated equipment, e.g. stoppers,chain transfers, roller tables etc.

...more

Double Crank Shears

Double crank shears are designed such that knives are perpendicular to the product whilst the cut is being performed Shears of this type used to cut medium size and large size sections Profiled knives will be used

Type : Cutting Force (kn)

...more

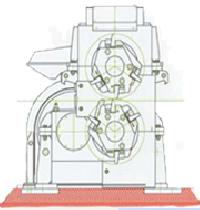

Rod Mill Block

ROD MILL BLOCK - The field-proven unit Modern rod mill processes are characterized by high productivity. The material is shaped at high mill delivery speeds and low product temperatures to obtain defined metallurgical effects, entailing high requirements to be met by the equipment. Therefore, the rod mill blocks operating in the high-speed range are of a particularly rugged design. Our Rod mill blocks feature Product speeds up to 100 ms (designed for 120 ms) through optimized mechanisms. Low gear speeds compared to roll speeds. Roll forces and roll torques designed for low temperature rolling. Large spaces to accommodate antifriction and friction bearings. Gear shafts supported in heavy-duty cylindrical roller bearings of special cage design and in precision angular-contact ball bearings. Five-year preventive maintenance intervals for gear units and power dividers.

...moreBe first to Rate

Rate This