Cable Roller

680 - 750 Per Piece

10 Piece (MOQ)

Conveyor Roller

Get Price Quote

We offer wide range of conveyor rollers. For any conveyor system application engineering and resulting layout is obviously custom-made. However, the equipment itself is often entirely standard. This is specially true of roller conveyor which include a high percentage of package conveyor usage. Roller conveyor ideal for in process operation and for any handling requirement.

Best Deals from Rollers

Supporting Roller

Get Price Quote

Supporting roller highlights. Oblige high spiral burdens. The thick-walled external ring empowers high spiral burdens, while lessening twisting and bowing anxieties. Long administration life. The delegated external ring running surface is gainful for applications where external ring tilting with respect to the track may happen or where edge stresses.

Deflector Roll

Get Price Quote

The production and processing of steel subjects mill components to combinations of enormous load, high temperature, corrosion, and abrasion. This has the potential to cause many problems throughout the processing line. Modern steel mills have recognized the importance of working with coated rollers. Thermal sprayed components are designed to permit steel to be processed more rapidly and efficiently.

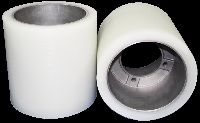

pu roller

800 Per Piece

We are the main supplier of this product.

tea roller

Get Price Quote

Vikram manufactures four types of high efficiency tea rollers - Single Action in two sizes - 36" & 46" Double Action in two sizes - 36" & 46" These Tea Rollers are efficiently engineered - fitted with heavy-duty bearings and robust body to take any amount of pressure. The Direct Drive mechanism ensures minimum power loss. The most important advantage is that standard components are used across the entire range of rollers, thus requiring just one set of spares.

Rice Rubber Roller

Get Price Quote

As we came across the performance of standard nitrile rubber rolls for de-husking of paddy in rice mills, with our in depth knowledge of polymer composites, we soon realized that this cannot be the ultimate material for de-husking, considering the three parameters of life in tonnage, de-husking efficiency and the most important of all the broken percentage. Hence few years back we started our laboratory experiments with different formulations, though we shall always remain in the process of improvisation in terms of all the three parameters, as of now we are in a position to offer to the industry, rolls made of elastomeric polymer composites which can give multiple times life while maintaining optimum de-husking efficiency through out its life. Now our focus is on reduction of broken percentage and for that we need full co-operation of the industry has a whole. We promise our full devotion of this mission of developing

plastic roller

Get Price Quote

plastic roller, Plastic Buckets

coal rolling

Get Price Quote

coal rolling, Steel Ingot, wagon component, center seal hat section

Industrial Rollers

Get Price Quote

Chevron Packing, Motor Fan, Filter, Bush HDPE, Veryus size Bearing Cover