Pneumatic Filter

We offer Pneumatic Filter. Applications: Recommended for increasing in life of Air Operated Equipment. Principle of working: Eliminates moisture, oil emulsions, condensed liquids and harmful foreign matter, thus maintaining a high level of purity. Features: • Pressure die cast aluminum alloy body • Centrifugal airflow separates moisture and oil emulsions. • Increased area of filter element traps solids • Increased quiet zone collects more liquid • Easy to dismantle. Specifications : 14’,38’,12’,&34’ Pipe sizes. BSP,BSPTr and NPT pipe thread standards as per IS -554 of 1964 • Low pressure Drop:2 ½ to 3% at maximum flow. • Polycarbonate bowl –Maximum air pressure: 14 kgcm2 at 1200F. Metal bowl 28kgcm2 at 1750F.

...more

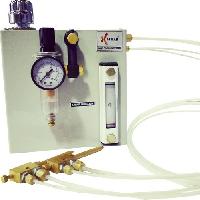

Oil Lubrication Systems (Mist Lubrication)

We offer Oil Lubrication Systems (Mist Lubrication). "MIST LUBRICATION SYSTEM" The finest solution for all the cutting tools and Conveyors. Applicable for all types of cutting tools and conveyors: Tool and cutter grinding Surface grinding operations Drilling Machines CNC Machines Shaping Machines Abrassive Cut off machines Milling operations Special Purpose Machining Operations. Benefits: • Instant cooling for the tool and the workpiece • Increase in production • Prolongs tool life by 50 to 200% easily • Visibility in machine operations • Takes away chips and saves time • Saves cleaning work • Improves surface finish • Saves costly coolant liquids, Avoids wastage • Prevents galling and sizing of taps Specially Designed for SPM'S, Milling centres, Turning Centers, All types of CNC'S & VMC's, Heavy Mill Roller Operations, all types of Cutting Tools, Extrusion Machines, Conveyors etc

...more

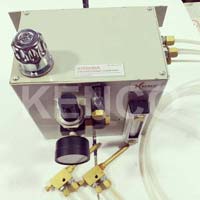

MIST LUBRICATION SYSTEM (AIR OIL MIX)

We are offering mist lubrication system . "mist lubrication system" the finest solution for all the cutting tools and conveyors. Applicable for all types of cutting tools and conveyors: tool and cutter grinding surface grinding operations drilling machines cnc machines shaping machines abrassive cut off machines milling operations special purpose machining operations. Benefits: • instant cooling for the tool and the workpiece • increase in production • prolongs tool life by 50 to 200% easily • visibility in machine operations • takes away chips and saves time • saves cleaning work • improves surface finish • saves costly coolant liquids, avoids wastage • prevents galling and sizing of taps specially designed for spm's, milling centres, turning centers, all types of cnc's & vmc's, heavy mill roller operations, all types of cutting tools, extrusion machines, conveyors etc

...more

Mist Cooling System

We offer Mist Cooling System . "MIST COOLING SYSTEM" The finest solution for all the cutting tools. GREEN LUBRICATION - GREEN MANUFACTURING Applicable for all types of cutting tools and conveyors: Tool and cutter grinding Surface grinding operations Drilling Machines CNC Machines Shaping Machines Abrassive Cut off machines Milling operations Special Purpose Machining Operations. Benefits: • Instant cooling for the tool and the workpiece • Increase in production • Prolongs tool life by 50 to 200% easily • Visibility in machine operations • Takes away chips and saves time • Saves cleaning work • Improves surface finish • Saves costly coolant liquids, Avoids wastage • Prevents galling and sizing of taps Specially Designed for SPM'S, Milling centres, Turning Centers, All types of CNC'S & VMC's, Heavy Mill Roller Operations, all types of Cutting Tools, Extrusion Machines, Conveyors etc

...more

Micro Lubrication Systems

Voltage : 230VAC,24VDC,110VAC

Automation Grade : Automatic

Brand Name : KENCO

...more

lubricating systems

25,750 Per Piece

Voltage : 24VDC,230VDC,110VAC

Automation Grade : Automatic

Brand Name : KENCO

...more

Industrial Lubrication System

We offer Industrial Lubrication System. Automatic Micro-Mist Oil Lubrication System (Micro-Fog) Principle of working: The lubricant is atomized to 4-6 micron sizes. They form a mist and are coalesced at the point of application to lubricate the two surfaces under friction. Advantages: * Can be easily installed on the existing machine. * Increases machine life * Simple to connect and operate. * With Oil control suitable lubricant is used, thus avoids lubricant wastage. * No extra cost on return pipe lines, pump and filtering systems as there is no recirculation. * As No wastage of oil nor any generation of fumes due to heating hence makes it Environmentally friendly. Applications: * Petroleum and chemical Industry * Refinery * Gear Boxes * Rolling Mills *Textile Mills * Machine Tools * High speed spindle bearings *Food processing Industry * Sugar Mills etc Models: Economic, Semi-Auto and Automatic. Specailly designed for Rolling Mills, Sugar Mill Roller Bearings, Conveyors, Food Industry, Textile Mills etc.

...more

Hydraulic Filter

We are offering hydraulic pressure line filter with cracking pressure valve.

...more

Fine Mist Sprayer

Centralized Lubrication System

centralised lubrication systems

22,000 Per Piece

Brand Name : KENCO

Voltage : 220-240 V

Automation Grade : Semi-Automatic

...more

Aluminium Pressure Die Casting

We manufacture and export varied range of high quality aluminium pressure die parts and components with our sophisticated facilities and skilled team. The components are as follows, * automobile components *railway components * electrical components * pneumatic filter components * hydraulic filter bodies * automotive engine parts * washing system components * aerospace and etc.

...more

Air Filter Regulator Lubricator

We offer air filter regulator lubricator. Kenco compressed air filter regualtor + lubricator unit applications: recommended for increasing in life of air operated equipment. Principle of working: eliminates moisture, oil emulsions, condensed liquids and harmful foreign matter, thus maintaining a high level of purity. Features: ¢ pressure die cast aluminum alloy body ¢ centrifugal airflow separates moisture and oil emulsions. ¢ increased area of filter element traps solids ¢ increased quiet zone collects more liquid ¢ easy to dismantle. Specifications : 14g, 38g, 12g,&34g pipe sizes. Bsp,bsptr and npt pipe thread standards as per is -554 of 1964 ¢ low pressure drop:2 â½ to 3% at maximum flow. ¢ polycarbonate bowl , maximum air pressure: 14 kgcm2 at 1200f. Metal bowl 28kgcm2 at 1750f.

...moreBe first to Rate

Rate ThisOpening Hours