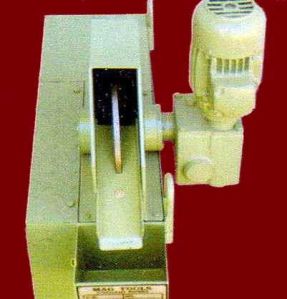

Paper Band Filtration System

65,000 - 5,000,000 Per Piece

Mag Tools Paper band filter unit is fabricated in steel. This entire unit is fixed on a coolant tank with a pump to supply coolant to the machine. The filtering paper is spread over an endless stainless steel mesh conveyor which is connected to a geared motor. this uniquely designed conveyor prevents overflowing of the liquid and the full width of the filtering paper is used. the movement of the filter paper is controlled by a float switch which actuates the geared motor.

Driven Type : Electric

Color : Black

Condition : New

Automatic Grade : Automatic

Power : 1-3kw

Application : Filtering Coolant

Certification : CE Certified

...more

Paper Band Filters

65,000 - 5,000,000 Per Piece

1 Piece(s) (MOQ)

Mag tools paper band filter unit is fabricated in steel. This entire unit is fixed on a coolant tank with a pump to supply coolant to the machine. The filtering paper is spread over an endless stainless steel mesh conveyor which is connected to a geared motor. This uniquely designed conveyor prevents overflowing of the liquid and the full width of the filtering paper is used. The movement of the filter paper is controlled by a float switch which actuates the geared motor. Mag tools paper band cum magnetic coolant clarifier involves our standard atp or tap model magnetic coolant clarifier. The powerful magnetic drum driven by a heavy duty geared motor designed to run continuously. The contaminated coolant liquid is first passed through the magnetic filter which separates almost 95% of the ferrous particles. The liquid further passes through filter which paper where all the nonferrous particles like grinding grit, stainless, brass or aluminum are filtered. As the porosity of paper gets filled up due to accumulates the liquid level rises. This triggers the float switch which starts the geared motor and fresh paper from the reel is pulled forward automatically. Now the liquid passes through the fresh paper and float switch shuts down the paper band cum magnetic coolant clarifier offer the excellent means of filtering both ferrous and nonferrous particles. Where high degree of purification id required and contaminates differ in from, size and composition. Paper band filtering system as a rule gives best results. Paper band filters are recommended for grinding, honing, transfer lines and machining center. It also can be used for rolling mills for filtering coolant which helps to improve the surface finish to the sheets. High efficient way of filtration guarantee fine finish, dimensional accuracy, increased tool life. Keeps your machine clean & reduces costly machine down time for periodical cleaning. Avoids bacterial growth and wastage of expensive coolants.

Application : Industrial

Power Source : Electric

...more

Paper Band Filter

Mag Tools Paper Band Filter unit is fabricated in steel. This entire unit is fixed on a coolant tank with a pump to supply coolant to the machine. The filtering paper is spread over an endless stainless steel mesh conveyor which is connected to a geared motor. this uniquely designed conveyor prevents overflowing of the liquid and the full width of the filtering paper is used. the movement of the filter paper is controlled by a float switch which actuates the geared motor. Mag Tools paper band cum magnetic coolant Clarifier involves our standard ATP or TAP Model Magnetic Coolant Clarifier. The powerful magnetic drum driven by a heavy duty geared motor designed to run continuously. OPERATION The contaminated coolant liquid is first passed through the magnetic filter which separates almost 95% of the ferrous particles. The liquid further passes through filter which paper where all the nonferrous particles like grinding grit, stainless, brass or aluminum are filtered. As the porosity of paper gets filled up due to accumulates the liquid level rises. This triggers the float switch which starts the geared motor and fresh paper from the reel is pulled forward automatically. Now the liquid passes through the fresh paper and float switch shuts down the geared motor. If required a push button switch may also be used for manually operating the geared motor and to bring the fresh paper forward. APPLICATION Paper band cum Magnetic coolant Clarifier offer the excellent means of filtering both ferrous and nonferrous particles. Where high degree of purification id required and contaminates differ in from, size and composition. Paper band Filtering system as a rule gives best results. Paper band filters are recommended for Grinding, Honing, Transfer lines and Machining center. It also can be used for rolling mills for filtering coolant which helps to improve the surface finish to the sheets. Advantages High efficient way of filtration guarantee fine finish, dimensional accuracy, increased tool life.Keeps your machine clean & reduces costly machine down time for periodical cleaning.Avoids bacterial growth and wastage of expensive coolants.Since the complete filtration system is automatic, No manual attention is needed.Where heavy stock removal increases the temperature of the coolant. This system of filtration due to sufficient exposure to air helps to control the same.The pump capacities will be according to the capacity of filter.Filters/ min. and above will be supplied with two or more pumps.Filters more than 400 liters will also manufactured as per customers requirements.The Specification for magnetic coolant Filters will be as per our catalogue. Features Filters both ferrous and nonferrous particles.Completely automatic operation, no manual attention needed.Continues trouble free operation.Prevents wastage of Coolants.High Surface finish & Dimensional accuracy on jobs guaranteed. Dimensional specification for Paper Band Cum Magnetic and Paper Band Filters

...more

Oil Skimmers

MAG TOOLS now has available small, cost effective Oil Skimmers for removing tramp oil from machine tool coolant tank. The MAG TOOLS wheel skimmer (WS) effectively removes floating tramp oil from water soluble coolants. In its magnetic version (MWS) it will even remove dispersed ferrous particles from the coolant. Tramp oil caused leaking hydraulic system & usage of way oil is an even present problem in the management of water soluble coolants. Tramp oil reduces the coolants cooling and lubrication properties and supports bacterial growth which produces corrosive sulphuric acid. Tramp oil will shorten the coolant lifetime drastically, sings of affected coolant are: The bad smell, rust stained poor quality parts and premature tool wear. Renewal of labour, purchase and disposal fees and machine down time. The oil skimmer removes up to 12 lifer of tramp oil per hour. After half an hour the coolant surface has been cleaned almost completely. Even now the skimmer still removes tramp oil. The Advantages of the MAG TOOLS Wheel Skimmer Low cost tramp oil removal for single machine application. Improves coolant performance. Improves coolant life. Simple design, few moving parts, low wear, very little maintenance required. Easy to install or retro-fit. Removes ferrous fines (M option) from the coolant. HOW IT OPERATES A steel wheel driven by a small close coupled gearbox reducer (0.25KW) is partially submerged in the soluble coolant. As it rotates the steel wheel picks up tramp oil & many other kinds of floating debris from the coolant surface. The wheel turns past a scraper which removes the oil from the wheel and guides the tramp oil into an existing separate tramp oil bin. The tramp oil bin may be equipped with soluble recovery option. Range of our products Magnetic Coolant Filters. Paper Band Cum Magnetic Coolant Filters. Hydro Cyclone Filters, vacuum Filters. Cartridge Filters, Magnetic Inline Filters. Centralized Coolant Filtration Systems. Mechanical Chip Conveyors, Scraper Conveyors. Screw Conveyors, Roller Conveyors. Filter Paper Rolls. Magnetic Chip Conveyors. Oil skimmers.

...more

Magnetic Coolant Separators

25,000 - 2,000,000 Per

The contaminated coolant from the machine is fed into the inlet of magnetic filter Magnetic coolant separator. As it passes through the gap between the drum and the body, the dust particles are arrested by the magnetic drum. A synthetic rubber roller mounted on springs, squeezes the dust and allows only dry power, which is further scraped out from the drum by scraper and is collected in the dust collecting tray. The filtration level achieved will be almost 95% for ferrous particles. These Magnetic Coolant Filters are manufactured in 2 Models, TAP & ATP

Power : 1-3kw

Packaging Type : Carton Box

Usage : Gringing, Iron Separation, Sponge Iron

Specialities : Rust Proof, Long Life, High Performance

...more

Magnetic Coolant Filters

30,000 - 3,000,000 Per

MAG TOOL�S Magnetic Coolant Filters designed for filtering coolant oils contaminated with ferrous materials. These equipments are light weight, compact design and easily be installed. These Magnetic Coolant Filters are manufactured in 2 Models, TAP & ATP MODEL � TAP : The body is fabricated in thick sheet metal. The magnetic drum is slotted type with powerful ring magnets. The magnetic field will be throughout the periphery. This produces magnetic field 30 mm above the drum. Very fine particles will be arrested without slip. The magnetic material used will not loose its strength even after number of years of use. Magnetic Coolant Filter with 100 to 1200 liters per minute filtering capacity are available in single construction. MODEL � ATP : The magnetic drum is made out of powerful ring magnets which also produces field 30 mm above the drum. Very fine particles will be arrested without slip. The magnetic material will not loose its strength even after number of years of use. These filters are available in 30 to 500 liter per minute filtering capacity. These filters can be coupled with Hydrocyclone, Paper Band, cartridge filters etc. And are also manufactured as per customer requirements. GEAR BOX : The drive of the drum is achieved by double reduction worm and worm wheel. The worms are made in high carbon steel, hardened and ground which run on sealed ball bearings. The worm wheels are made in high wear resistance materials. An oil indicator is provided to ensure the level of oil in the gear box. This box is designed for continues and trouble free running for years. WORKING PRINCIPLES : The contaminated coolant from the machine is fed into the inlet of magnetic filter. As it passes through the gap between the drum and the body, the dust particles are arrested by the magnetic drum. A synthetic rubber roller mounted on springs, squeezes the dust and allows only dry power, which is further scraped out from the drum by scraper and is collected in the dust collecting tray. The filtration level achieved will be almost 95% for ferrous particles. APPLICATION : These Filters can be used with all types of Grinding machines such as Cylindrical, Center less, internal, Surface, Double-disc & Roll-grinding machines. These can also be used for filtering honing oil of Honing machines.

Country of Origin : India

Type : Coolant Filter

Brand Name : Mag Tools

Material : Mild Steel

Shape : Square

Color : Apple Green

Voltage : 440V

Condition : New

Corrosion Resistance : Yes

Finishing : Powder Coated

Motor Power : 0.5hp

Warranty : 1 Year

Operating Type : Semi Automatic

Packaging Type : Wooden Box

Particle Size : 100 Micron

Filtration Capacity : 50 Microns

Usage : Textile Industry, Pharma Industry, Water Filter, Air Filter

Specialities : Hassle-Free Functioning, Ease Of Install, High Tensile, High Quality, Heat Resistance, Durable

...more

Magnetic Coolant Filter

30,000 - 1,000,000 Per Piece

Mag tool's magnetic coolant filters designed for filtering coolant oils contaminated with ferrous materials. These equipment's are light weight, compact design and easily be installed. These magnetic coolant filters are manufactured in 2 models, tap & atp the body is fabricated in thick sheet metal. The magnetic drum is slotted type with powerful ring magnets. The magnetic field will be throughout the periphery. This produces magnetic field 30 mm above the drum. Very fine particles will be arrested without slip. The magnetic material used will not loose its strength even after number of years of use.magnetic coolant filter with 100 to 1200 liters per minute filtering capacity are available in single construction. The magnetic drum is made out of powerful ring magnets which also produces field 30 mm above the drum. Very fine particles will be arrested without slip. The magnetic material will not loose its strength even after number of years of use.these filters are available in 30 to 500 liter per minute filtering capacity. These filters can be coupled with hydrocyclone, paper band, cartridge filters etc. And are also manufactured as per customer requirements. The contaminated coolant from the machine is fed into the inlet of magnetic filter magnetic coolant separator. As it passes through the gap between the drum and the body, the dust particles are arrested by the magnetic drum. A synthetic rubber roller mounted on springs, squeezes the dust and allows only dry power, which is further scraped out from the drum by scraper and is collected in the dust collecting tray. The filtration level achieved will be almost 95% for ferrous particles. These magnetic separators magnetic filters can be used with all types of grinding machines such as cylindrical, center less, internal, surface, double-disc & roll-grinding machines. These can also be used for filtering honing oil of honing machines.

...more

Magnetic Chip Conveyors

50,000 - 5,000,000 Per Unit

FINE � Light and sharp chips generated from gear shaves, Gear Hobbers, Spline cutting machines, SPM deep hole drilling machines, broaching machines, Press shops and Heat treatment shops coming with large amount of coolant tend to escape with the coolant and cause damage to the pump and effects surface finish. Plain sheet magnetic conveyor help attract ferrous chips from coolant & separates coolant from chips. Thus the coolant is free from chips and the conveyor acts as magnetic filter for the coolant. The moving permanent magnets mounted on endless chain underneath the stationary stainless steel sheet attracts ferrous chips and slide them on to the plate to the discharge end. The coolant separated from chips flows to the coolant tank through an over flow so that even floating chips get attracted by moving magnets and get conveyed. MAG TOOLS Magnetic plain sheet type conveyors being sleek in construction can be introduced in to small cross sectional openings in machine tools. Since Conveyors are custom built, different configuration and profiles can be made to suit specific applications.

Finishing : Powder Coated

Machine Weight : 200-300 Kg, 300-40 Kg, 400-500 Kg

Rated Power : 1-3 KW

Packaging Type : Wooden Box

Belt Length : 10-20 Feet, 20-30 Feet, 30-40 Feet, 40-50 Feet

Belt Width : 10-20 Inch, 20-30 Inch, 30-40 Inch

Loading Capacity : 5-10 Kg, 10-15 Kg, 15-20 Kg, 20-25 Kg

Usage : Moving Goods, Coal & Fly Ash Handling, Packaging

Specialities : Vibration Free, Unbreakable, Scratch Proof, Long Life, Heat Resistant, Excellent Quality, Corrosion Proof

Type : Vertical Conveyors

Brand Name : MAG TOOLS

Shape : Square

Color : Green

Voltage : 440V

Condition : New

Automatic Grade : Automatic

Driven Type : Motor

Belt Material : Stainless Steel

Phase : Three Phase

Country of Origin : India

Corrosion Resistance : Yes

Speed Adjustable : No

Machine Material : Mild Steel

...more

Hydrocyclone Coolant Filters

FEATURES No moving parts hence least maintenance. Continues filtration avoids shut down of machine for periodical cleaning Improved surface finish and dimensional accuracy of components. Coolant life increases indefinitely. Grinding wheel life improved. Aids bacteria control. Higher production potential. WORKING PRINCIPAL: Hydrocyclone classification offers a very simple and unique approach in gravity style clarification. There are no moving parts in this continuous operating centrifuge.The classification begins when the dirty liquid is pumped at a pressure of 2 kgs./cm2 into the unequally designed head.The head permits the dirty liquid to begin rotation as soon as it enters the helical axial distributor vane.The action of the helical axial distributor vane introduces the dirty liquid into the cell.In a narrow thin band.This action reduces the intersecting angle between the incoming dirty liquid which reduces undesirable turbulences and aids to ensure maximum clarification through lower energy losses as the dirty liquid flows downwards through the helical distributor vane, a free primary vortex.Develops along the outer wall of the carefully designed cell and accelerates downwards. Due to the high cyclonic action the solid particles accumulated near the inner wall of the cell are carried downwards and discharged with about 2.5% of liquid through the outlet orifice Due to orifice opening a differential pressure generates between the inlet and outlet. This opening allows air to enter the cell creating a secondary rising low pressure vortex.Clean fluid rises through the center opening of the distributor vane.Discharged out through the outlet of the head. The discharged solids with a small amount of liquid is collected in the sludge trolley. DEGREE OF SEPARATION: The degree of separation is affected by the inlet and outlet pressure by the specific gravity of the coolant, the percentage of contaminates and the amount of foreign tramp oils.As a general rules soluble oil and water mixture containing steel and abrasive particles can be clarified to a standard or 10-20 microns. Heavier particles may be clarified up to 5 microns. MAINTENANCE : Under normal operating conditions the only wear area is the orifice which can easily be replaced by a spare one. Preventive measures must be taken to avoid the possibility of clogging the orifice. In case of clogging unscrew the orifice and clean with a pin. GENERAL OPERATION : The series is designed for easy installation and efficient liquid classification. After a minor piping connection normally only a 3 phase power supply connection completes the installation. The dirty coolant enters into the pump tank through wire mesh entry tray, which prevents any large pieces of sludge or foreign material from entering the system. The filter pump delivers the coolant to the Hydrocyclone unit where the particles are separated from the liquid and discharged through the outlet orifice into the sludge trolley. As the sludge settles into the trolley, the surplus coolant overflows back to the inlet entry tray. The clean coolant is delivered to the machine from the Hydrocyclone through the clean coolant outlet. The clean coolant accumulated in the tank receive from the pressure relief value can be utilized for another machine by fixing one more small pump. The clean coolant accumulated in the tank receive from the pressure relief value can be utilized for another machine by fixing one more small pump.

...more

Filter Papers

We are take pride in introducing ourselves as one of the highly renowned Filter Paper Manufacturers and filter paper suppliers. We manufacture Filter Papers in accordance of highest technical specification. The variety of filter papers manufactured by us consists of Industrial Filter Paper etc. As the filter papers are manufactured using finest quality material, these are also offered at very reasonable prices by us.

...more

Paper Band Magnetic Coolant Filtration System

50,000 - 500,000 Per

1 Set (MOQ)

Fully automated our band filters are easy to operate and provides cost effective solution for filtration. These filters are specially designed for space efficiency and require only 20% of the space as compared to other conventional band filters. The hydrostatic head and the perfect sealing of the machine ensure that there is no leakage or overflow of the material and high filtration efficiency is achieved. Engineered to precision, these filters well suited for high flow rate and dirt content. Paper cartridge, washable cartridge, and stack type filter elements are available. System used to achieve final filtration level. Range: 30 lpm to 1000 lpm in one module. Suitable to max, working pressure 30 bar & pressure drop 0f 3 bar across filter. Clarity level : 75 microns to 3 microns.

Packaging Type : Wooden Box

Particle Size : 20 Micron

Filter Length : 100 meters

Overall Weight : 200Kg

Filtration Capacity : 10 Microns, 20 Microns, 30 Microns

Usage : Textile Industry, Pharma Industry, Water Filter, Air Filter, Griding Machines

Specialities : Hassle-Free Functioning, Ease Of Install, High Quality, Heat Resistance, Durable

Flow Capacity Range : 100 Cfm, 150cfm, 200cfm

Brand Name : MAG TOOLS

Material : Mild Steel

Shape : Square

Color : APPLE GREEN

Voltage : 440V

Condition : New

Finishing : Powder Coated

Power : 5Kw

Motor Power : 0.5 HP

Warranty : 1 Year

Country of Origin : India

Corrosion Resistance : Yes

Operating Type : Automatic

Is It Washable : Yes

...more

Coolant Filter Paper

1,500 - 100,000 Per

Coolant filter paper These equipments are light weight, compact design and easily be installed. These Magnetic Coolant Filters are manufactured in 2 Models,

Type : Coolant Filter Paper

Material : Cellulose, Cotton Pulp

Condition : New

...more

Compact Band Filter

85,000 - 5,000,000 Per Piece

Fully automated our compact band filters are easy to operate and provides cost effective solution for filtration. These compact band filters are specially designed for space efficiency and require only 20% of the space as compared to other conventional compact band filters. The hydrostatic head and the perfect sealing of the machine ensure that there is no leakage or overflow of the material and high filtration efficiency is achieved. Engineered to precision, these compact band filters well suited for high flow rate and dirt content.

Driven Type : Electric

Color : Black

Automatic Grade : Automatic

Power : 1-3kw

Application : Grinding Lapping, Gun Drilling, Wire Drawing

Certification : CE Certified

...more

Chip Conveyors

65,000 - 10,000,000 Per Piece

Hubli filters and conveyors hinged steel belt chip conveyors are been specially designed keeping in mind the hazards that are normally encountered with conventional chips and swarf conveyors, the hinged steel belt is pressed in extra heavy duty sheet and perfect guiding of rollers ensures minimum friction and noise free operation. The body compact in size occupies small space but due to extra chip space can handle large volume of chips.

Finishing : Powder Coated

Machine Weight : 100-200 Kg, 200-300 Kg, 300-40 Kg

Rated Power : 1-3 KW, 3-5 KW, 5-7 KW

Packaging Type : Wooden Box

Belt Length : 10-20 Feet, 20-30 Feet, 30-40 Feet, 40-50 Feet, 50-60 Feet, 60-70 Feet, 70-80 Feet, 80-90 Feet, 90-100 Feet

Belt Width : 10-20 Inch, 20-30 Inch, 30-40 Inch

Application : Moving Goods

Specialities : Long Life, Heat Resistant, Excellent Quality

Type : Horizontal Conveyors

Brand Name : MAG TOOLS

Color : Green

Voltage : 440V

Condition : New

Automatic Grade : Semi Automatic

Driven Type : Motor

Belt Material : Stainless Steel

Phase : Three Phase

Country of Origin : India

Corrosion Resistance : Yes

Speed Adjustable : No

Machine Material : Mild Steel

...more

Chip Centrifuge

We are a well established Chip Centrifuge Manufacturer and chip centrifuge exporter. At Mag Tools Hubli, we have chip centrifuge, Chip Centrifuge Filters etc., with us. The Chip Centrifuge offered by us is basically a device that is used for separating liquid, cutting oil etc., from a mixture of metal chips and larger pieces of metal. Hence, chip centrifuge manufactured by us is a very cost effective item. Chip Centrifuge becomes progressively more important in today�s machine shops. Environmental laws limit the maximum residual coolant that can be retained in transported swarf and economically, reclaiming expensive coolant and the increased sales value of relatively dry chips are of vital importance. The Mag Tools offers small centrifuge units for single or small groups of machine with capacities upto 1000 liters per hour. ADVANTAGES OF MAG TOOLS CHIP CENTRIFUGE: Adjustable speed to fit individual requirements. Minimum number of parts, resulting in smooth running and low maintenance. Heat treated, one piece long life bowl. Superb de-oiling. Small and compact in size. Trouble free performance. Maximum oil reclaiming from chips Low price. HOW IT OPERATES Small metal chips are continuously and regularly fed in to the centrifuge funnel by a feeding conveyor. The chips slide into the fast spinning wringer bawl and are accelerated upto the bowls RPM. High G-forces drive the chips up the bowls side wall and over the coolant exit slots toward the upper edge of the bowl. In this process the coolant is wrung off the chips and forced out via the coolant exit slots. The dried chips pass over the upper bowl edge and are guided via the wringer housing and discharge funnel into an extractor conveyor or swarf bin. DESIGNS Mag Tools Centrifuge Model MTC�10, MTC-16 and MTC-20 are designed and constructed to offer high performance, maximum reliability and long lifetime with a minimum amount of maintenance. The bowl is manufactured from one price of specially heat treated alloy steel, using high precision machining techniques. The main shaft and bearing housing are machined to precise dimension and tolerances, the total assembly is mounted on vibration damping rubber pads. MAG TOOLS Manufactures the following machine tool, chip conveying and Filtration System Magnetic Coolant Filters Paper Band Cum Magnetic Coolant Filters Hydro Cyclone Filters Cartridge Filters Vaccum Filters Magnetic Chip Conveyor Mechanical Chip Conveyor Scraper Conveyor Screw Conveyor Roller Conveyor Oil Skimmer(Disk & Belt Type) Centralized Coolant Filtration Systems Chip Centrifuge Aluminum Chip Conveyor Cum Drum Filter Chip Crusher Presser Band Filters Compact Band Filters Oil Chilling Units Filter Paper Rolls

...more

Aluminium Chip Conveyors

50,000 - 500,000 Per Unit

mag tools new aluminium chip conveyor cum drum filter was developed and performance � proven by bunri industries, ltd., japan. the aluminium chip conveyor cum drum filter offers the machine tools industry a highly effective method for the difficult task of separating aluminum chips, fines and turnings from flowing coolant. it employs a new and unique concept that incorporates a drag conveyor with drum (rolling) filters. numerous advantages include: features: removes floating and suspended chips as easily as chips and fines. self-clearing filter eliminates problems of clogging. improves part quality by improving coolant quality. prolongs coolant life. continues trouble free operation. an efficient solution for positive separation the new aluminum chip conveyor cum drum filters is the only conveyor available that can receive flowing coolant loaded with aluminum turnings, capture those turnings inside, and then allow only clean coolant to exit. it is available for use with a single machine tool, or as part of a central integrated coolant cleaning system. how it operates the dirty tank coolant inlet is the first area to receive chips, turnings, fines and coolant from the machine tool. there, large chips settle to the bottom where they are removed by a drag conveyor. all coolant must then pass through a series of drum filters. there a ss drum screen, scraped, captures smaller chips and lighter weight chips away by a scraping plate or flushed by back wash arrangement and then remove a by the drag conveyor. the separated coolant exits through the inside of the drum filter to a clean coolant exit. the separated coolant can be now either pumped back to the machine tool, or pumped through another filtration system for secondary cleaning. (mag tool�s hcf filter compliments the aluminum chip conveyor by providing secondary coolant filtration. it filters coolant clean up to 25 microns.)

Finishing : Powder Coated

Machine Weight : 200-300 Kg, 300-40 Kg, 400-500 Kg, 500-600 Kg

Rated Power : 1-3 KW, 3-5 KW

Packaging Type : Wooden Box

Belt Length : 10-20 Feet, 20-30 Feet, 30-40 Feet, 40-50 Feet, 50-60 Feet, 60-70 Feet, 70-80 Feet, 80-90 Feet, 90-100 Feet

Belt Width : 10-20 Inch, 20-30 Inch, 30-40 Inch

Loading Capacity : 5-10 Kg, 10-15 Kg, 15-20 Kg, 20-25 Kg, 25-30 Kg, 30-35 Kg, 35-40 Kg, 45-50 Kg

Usage : Moving Goods, Coal & Fly Ash Handling, Packaging

Specialities : Vibration Free, Long Life, Heat Resistant, Excellent Quality, Corrosion Proof

Type : Horizontal Conveyors

Brand Name : MAG TOOLS

Shape : Square

Color : Green

Voltage : 440V

Condition : New

Automatic Grade : Automatic

Driven Type : Motor

Belt Material : HINGED METAL BELT

Phase : Three Phase

Country of Origin : India

Corrosion Resistance : Yes

Speed Adjustable : No

Machine Material : Mild Steel

...more

Hinged Steel Belt Chip Conveyors

It has been specially designed keeping in mind the hazards that are normally encountered with conventional chips and swarf Conveyors, The Hinged steel belt is pressed in extra heavy duty sheet and perfect guiding of rollers ensures minimum friction and noise free operation. The body compact in size occupies small space but due to extra chip space can handle large volume of chips. The pitch of the hinged steel belt is 2.5 inch and 1.5 inch, width varies from 6 inch to 24 inch depending upon the volume of chip to be handled. Available in various configurations straight or inclined from 15 degree to 75 degree. Variable or fixed speed drives as per requirement can be supplied. A safty clutch arrangement with adjustable torque prevents damage to metal belt and the drive, in case of jamming. Where large volume of chips are produced, such as in multi Spindle Automats, CNC Machining Center, SPM�s CNC Turning center, etc. are to handle components in heat treatment furnaces, the continuous operation ensures least machine down time and minimum labour.

...moreBe first to Rate

Rate ThisOpening Hours