Zinc cut wire shot

Zinc Cut Wire is a relatively soft abrasive with a high denisity giving it good kentic energy. It creates less dust then steel or aluminum abrasives, has a long life cycle and causes relatively low wear on machine parts. Zinc Cut Wire is used in applications where a soft material is required for de-flashing and deburring zinc or aluminium die castings and it is also used to strip paint and powder coatings without damaging the substrate.

...more

zinc cut wire

Zinc Cut Wire is a relatively soft abrasive with a high denisity giving it good kentic energy. It creates less dust then steel or aluminum abrasives, has a long life cycle and causes relatively low wear on machine parts. Zinc Cut Wire is used in applications where a soft material is required for de-flashing and deburring zinc or aluminium die castings and it is also used to strip paint and powder coatings without damaging the substrate.

...more

White Fused Alumina

White Fused Alumina is mainly used is as a recyclable abrasive in blast cabinets and blast rooms, where high purity of the abrasive is required. Because of its low iron content, white fused alumina is often used in blasting operations where iron contamination on the non-ferrous metal substrate is not allowed. White Fused Alumina is the purest alumina and it is very hard and sharp with a fast cleaning rate.

...more

Steel Grits

High carbon steel shot is used in the majority of the wheel blast applications and creates a dimpled, peened surface. Only the shot’s skin suffers from the impact and very thin flakes will progressively part from the shot, which itself stays round throughout its life cycle. Our steel shot is very durable with high resistance to impact fatigue, giving it an effective and quick cleaning rate. Our high carbon steel shot is used in various applications like; desanding, descaling, cleaning, shot peening etc.. The centrifugal atomization process and double heat treatment at the Airblast plants, as well as continues quality control measures, ensures the shot to be of the highest quality.

...more

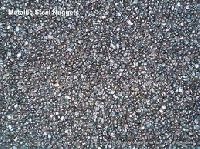

Steel Cut Wire Shot

Stainless Steel Cut Wire is used for cleaning and peening applications where ferrous contamination can’t be tolerated. It produces a very bright surface, maintains its shape longer then cast abrasives and it produces a dust free surface. Stainless Steel Cut Wire is available as cut or conditioned and with various chemical compositions.

...more

stainless steel cut wire

Stainless Steel Cut Wire is used for cleaning and peening applications where ferrous contamination can’t be tolerated. It produces a very bright surface, maintains its shape longer then cast abrasives and it produces a dust free surface. Stainless Steel Cut Wire is available as cut or conditioned and with various chemical compositions.

...more

Shinox - Stainless Steel Shot

Companies which are casting or fabricating stainless, aluminum or light alloy parts can safely use stainless steel abrasives, since they secure the parts from ferrous residue contamination and it achieves effective blasting performances. Stainless steel abrasives are very durable and are being used for deburring, blast cleaning and surface finishing. Less dust is created by using Shinox and it gives the surface a bright appearance.

...more

metallic abrasives

High carbon steel shot is used in the majority of the wheel blast applications and creates a dimpled, peened surface. Only the shot’s skin suffers from the impact and very thin flakes will progressively part from the shot, which itself stays round throughout its life cycle. Our steel shot is very durable with high resistance to impact fatigue, giving it an effective and quick cleaning rate. Our high carbon steel shot is used in various applications like; desanding, descaling, cleaning, shot peening etc.. The centrifugal atomization process and double heat treatment at the Airblast plants, as well as continues quality control measures, ensures the shot to be of the highest quality.

...more

low carbon steel shot

Low carbon steel shot has a lower hardness than high carbon steel shot. Because of its microstructure it resist impact well until the moment it suddenly scatters and turns into dust. It is often used for flash descaling. Since low carbon steel shot is softer it not possible to crush it into grit, which is therefore not available.

...more

High Carbon Steel Grit

High carbon steel shot is used in the majority of the wheel blast applications and creates a dimpled, peened surface. Only the shot’s skin suffers from the impact and very thin flakes will progressively part from the shot, which itself stays round throughout its life cycle. Our steel shot is very durable with high resistance to impact fatigue, giving it an effective and quick cleaning rate.Our high carbon steel shot is used in various applications like; desanding, descaling, cleaning, shot peening etc.. The centrifugal atomization process and double heat treatment at the Airblast plants, as well as continues quality control measures, ensures the shot to be of the highest quality. High Carbon Steel GritHigh carbon steel grit produces an etched or angular surface profile and is well suited for cleaning, descaling, etching and desanding applications. Our high quality steel grit has a long service life and is used in both wheel blast machines and blast rooms. High Carbon Steel Grit GP has the lowest hardness in the range of 42 to 52 HRC and is also revered to as angular shot, because the grit will get a round shape during its lifetime. It Is mainly used in wheel blast machines and it has good results in the foundry industry because it cleans faster with little increase in maintenance costs and machine parts wear. GP is used for cleaning, descaling and desanding. High Carbon Steel Grit GL has a medium hardness in the range 53 to 60 HRC. It is used in wheel blast machines and blast rooms and is particularly suited to heavy descaling and surface preparation requirements. Although GL is of medium hardness, it also loses its angular shape during shot blasting. High Carbon Steel Grit GH. The maximum hardness ranging from 60 to 64 HRC. It stays angular in the operating mix and is therefore ideally suited for surface etching requirements. GH is often used in blast rooms for quick cleaning and to achieve an anchor profile prior to coating. PRODUCTION Airblast Abrasives has two purpose built production facilities for the production of High Carbon Steel Abrasives covering an area of 4.000 m2. To produce a uniform spherical grain, the plant is using state of the art technology to fabricate the high quality product :• Centrifugalizing process instead of high water jet streams to atomize the liquid steel into more spherical and uniform particles.• A second heat quenching gives the abrasive a more uniform chemical and internal structure, making the abrasive less brittle.• Air quenching instead of water quenching results in fewer micro cracks and thus a better durability of the abrasive. High Carbon Steel grit and shot are produced by atomization of molten steel followed by a series of thermal and mechanical treatments in order to give the product the desired characteristics.1. Careful selection of the scrap.2. Melting the scrap in the electric induction furnace, adding the necessary alloys.3. Atomisation through centrifugalizing to get a uniformly shaped grain.4. Screening to get the right grain sizes5. Spiralling to remove the irregular shaped shot6. Quenching for superior particle integrity with minimal stress cracks7. Tempering8. Second screening9. Packaging. (photo) Before, during and after the process, our in-house quality control department continuously verifies the consistency and the quality of our abrasives. Our Research and Development laboratory constantly strive to improve the key performance factors of the abrasive and optimise the production process. Packaging The product is delivered according to the customer’s choice of packaging:• Bags 40 x 25 kgs. on a EURO pallet• Bags 50 x 20 kgs. on a EURO pallet• Big bags of 1000 kgs.• Other packaging upon request.To ensure quick delivery Airblast-Abrasives B.V. has all grades of high carbon steel grit and shot available from stock, in 25 kgs. bags on a EURO pallet.Production

...more

Glass Beads

Glass beads are a reusable abrasive and are mainly used in blast rooms and blast cabinets. Glass beads contain no free iron to cause corrosion on non-ferrous surfaces, therefor glass beads are very suitable to use on all types of metals. Since it doesn’t create an anchor profile, it is mainly used to clean a substrate without roughening it or to polish the surface.

...more

Garnet

Garnet is a natural mineral abrasive which is irregularly shaped with polished edges, it contains no heavy materials and has a low level of free silica. Because garnet is very heavy and hard for a mineral abrasive it accomplishes a fast cleaning rate. It is being used to remove rust, mill scale, old coatings and to clean buildings. Some of the advantages of garnet are; fast cleaning, relatively low dust generation (as compared to copper- or coal slag), environmental friendly and reusability.

...more

Chilled Iron Grit

Chilled iron is a hard abrasive making it suitable for etching purposes, but less resistant to impact. During the blasting process chilled iron breaks at an angle producing a permanent mixture of sharp grit with the ability to roughen up the hardest surface and clean quickly. It is suitable to be used in blast rooms for fast cleaning and edging but shouldn’t be used in wheel blast machines, since it quickly wears down the machines parts.

...more

Carbon steel shot

Low carbon steel shot has a lower hardness than high carbon steel shot. Because of its microstructure it resist impact well until the moment it suddenly scatters and turns into dust. It is often used for flash descaling. Since low carbon steel shot is softer it not possible to crush it into grit, which is therefore not available.

...more

Carbon steel cut wire

Carbon steel cut wire are made of from steel wire cut in pieces. The cylindrical cut wire is mainly used in the foundry and construction industries for heavy duty applications like de-sanding, descaling and cleaning. The cylindrical cut wire achieves a high cleaning efficiency and has a long service life

...more

Brown Fused Alumina

Brown fused Alumina is mainly used as a recyclable abrasive in blast cabinets and blast rooms. Because of its low iron content, alumina is often used in blasting operations where iron contamination on the non-ferrous metal substrate is not allowed. Aluminium oxide is a very hard and sharp abrasive that cleans rapidly. It leaves an anchor profile prior to coating and is suitable for removal of scale, rust and old coatings. Furthermore it is used for ceramic grinding wheels, refractory applications and polishing and grinding.

...more

Aluminium Cut Wire Shot

Aluminium Cut Wire shot is used for the blast cleaning, surface finishing and deburring of mainly aluminium castings and forgings. It is very durable and leaves no ferrous residue on the substrate.

...more

aluminium cut wire

Aluminium Cut Wire shot is used for the blast cleaning, surface finishing and deburring of mainly aluminium castings and forgings. It is very durable and leaves no ferrous residue on the substrate.

...more

abrasive blasting equipment

Be first to Rate

Rate ThisOpening Hours