Ribbon Blender

Get Price Quote

1 Piece (MOQ)

We manufacture & Supply Ribbon Blender are efficient in proper mixing of different powders, dry & wet ingredients. These ribbon mixers or ribbon blenders are made of best grade raw material and are suitable for mixing pickles, pre-cooked dal, ready-to-eat mixes and chemicals. Available in capacities ranging 100 lts to 3,000 lts these are in high demand in the market.Features : Efficient in proper mixing of different powders, dry & wet ingredients. Made of best grade raw material. Suitable for mixing pickles, pre-cooked dal ready-to-eat mixes and chemicals. Available in capacities ranging 100 lts to 3,000 lts.

Biomass Pellet Making Machine

Get Price Quote

1 piece (MOQ)

Best Deals from Animal Feed Making Machine

Metering Screw Feeder

25,000 Per Meter

10 Meter (MOQ)

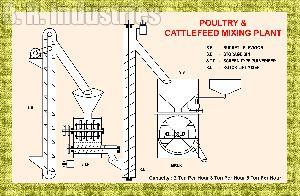

Poultry & Cattle feed Making Plant

Get Price Quote

1 Set(s) (MOQ)

specification of blended spices and coriander grinding plants. consists of 3 nos of screw conveyor (material lifting from one machine to another). to first grinding machine -> through screw conveyor -> second grinding machine-> here you get the final product (fine powder) final product and 2 nos of micro pulverisers(grinder) for 2 stage grinding of mix masala or coriander if mixer is attached to the plant final product store into the mixer and cooling of fine powder also takes place before bagging in the mixer. it is an continuous process of grinding and only 2-3 mens required while running the plant. plant available in capacities :

Hammer Mill

Get Price Quote

Ribbon Mixer

Get Price Quote

ribbon blender comprises of a u-shaped horizontal trough and a specially designed double helical ribbon agitator rotating within. ribbon blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. our qualified technicians specially designed and configure the ribbons and are also carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge.

Biomass Pellet Making Machine

550,000 Per Set

1 Set(s) (MOQ)

We have carved a niche for ourselves as one of the distinguished Manufacturers, Exporters, and Suppliers of Biomass Pellet Making Machine in Hyderabad, Telangana. The machines that we manufacture are highly appreciated by the clients for its high performance. The Biomass Pellet Making Machine is simple to operate and is made under the supervision of skilled professionals. The efficient Pellet Making Machine can be obtained from us at market leading prices. The Pellet Making Machine is meant for making pellets using raw materials such as:Saw Dust, Ground Nut Shell, Coffee Husk, Rice Husk, Wood Waste, Soya Husk, Cotton Stalk, Neem Cake, Turmeric, Charcoal, Tobacco, Bleaching Earth, Carbon Black, Cardboard Waste, Compost, Fly Ash, Household Waste, Paper Waste, Pulp, and Coal Dust for using as fuels.

Impact Hammer Mills

Get Price Quote

Best suited for Limestone, Coal, Gypsum and softer ores Reliable performance & increased output Rugged design and construction Suitable for secondary and tertiary applications Un-effected by foreign particles

ribbon blander

Get Price Quote

We are offering ribbon blander. Here, you can add new products, along with detailed information. Fill in the details accurately and upload a clear image with a close-up of the product.

Hammer Mill

Get Price Quote

1 Piece(s) (MOQ)

Ask Engineering Works is specialised in manufacturing quality hammer mills or better known as industrial shredders. They are widely used in recycling industries among others. We distinguish ourselves by manufacturing and supplying high-quality and affordable shredder installations. We think along with you to create the best solution for your requirements. Our company provides excellent quality machines to complete your entire work brilliantly. We have developed our machines as per your expectations. These machines provide amazing support to you and your company with high performance and efficiency. You will find our machines in differing processing branches of recycling industries such as: • Tires recycling • Cable recycling • Wood recycling • Plastic recycling • Cable recycling Along with that, we provide the best solutions to the following operations. • Processing and reducing industrial waste. • Drying of the granules • Washing of the granules • Separating different raw materials. • Storing bulk material. Do you want a good quality hammer mill? Here we are the best hammer mill suppliers in Hyderabad. The machines that we produce are innovative and can be used for crushing and shredding of the assorted aggregate materials. The resultant products are then worked on using a hammer mill to get smaller pieces. Our machines are suitable for the toughest work in all kinds of environments. It helps in reducing semi-moist and dry materials. Features • Great capacity • Simple installation • High performance • Assured accurate sizing • Low maintenance The machine that you get from our company is quality assured. We test all our machines to make sure that there are no faults in it. Therefore get products for your industry from our company. We follow strict delivery rules and ensure to supply our products on time without any delay. Our company is the best Hammer Mill Supplier In Hyderabad, India. In case of any kind of problems contact us. We provide our clients with 24/7 customer support. Our executives will solve all your problems and doubts.

Ribbon Blender Mixer

Get Price Quote

By following a strict selection process, we source the entire range of raw materials from the certified vendors. Thus, we make sure that our finished goods will be flawless. Backed by a team of proficient quality inspectors, we provide only quality assured products to the customers. Our ribbon blender mixer is available with a working speed of 300rpm.

Screw Feeders

Get Price Quote

Material is extracted in batches from a silo and then fed into a weigh hopper. Feed rates of smaller screws are more accurate than those achieved with larger diameters. Consistently, larger Screw Feeders require micro-feed aids in order to improve their poor feeding accuracy.

Hammer Mill

Get Price Quote

Impact pulveriser is a high speed swing type pulveriser the fine Powder is taken out from the grinding chamber by the blower suction through rotating whizzer which rotates in the whizzer cone. The particles size is regulate by the adjusting the gap of the whizzer in the whizzer cone and the oversize particle is stop form coming out and feed back in to the grinding chamber for further grinding until the desire mesh size is achieved

AUTOMATIC POULTRY AND CATTLE FEED GRINDING PLANT

Get Price Quote

Simple Design- Study Structure Easy to Operate, Supervise and Maintenance are the basic Principles on which we have designed our Automatic Feed Grinding Plants. Our Plants therefore, can conveniently be installed even at remote places where technical aid is not easily available. Our Automatic feed Plants are placed on Single floor without any super structure. We have avoided complicated and unnecessary sophistication and automisation, where failure of one part in any machine results in complete Breakdown of Production. We have developed Plants tailored to suit enterprising farmers (8 Tons Shift), Commercial farmers and Small Town Feed Producers (16-20 Tons Shift), Government Feed Distribution Programmes(20-24 Tons Shift), and a commercially operated Feed Plant (50 - 75 Tons shift). We are Pioneers in this field, being the first to manufacture Automatic Feed Grinding Plants of 30 Tons Shift in the Country in the year 1970. We are the Leading suppliers of Feed Plants in the country with more than 200 Big and Small Plants working throughout the Nation.

Molasses

Get Price Quote

We are engaged in the importing, exporting and supplying high quality Molasses for the domestic and international clients. Molasses are commonly used in the preparation of liquors during their fermentation process. These Molasses are strictly inspected and certified by the experts to ensure their purity. Our company is making Molasses available to the clients at reasonable rates.

Ribbon Blenders

Get Price Quote

Essaar machineotech Ribbon Blender is primarily designed for use with dry materials, although gas and liquid streams can also be introduced.

Reversible Hammer Mill

Get Price Quote

Hammer Mills are very old yet widely used among various types of crushers. It is a type of centrifugal crusher. The crusher hammers are symmetrically designed on rotors and hence can work in both the directions. Reversal of the direction permits the user to use the opposite face of the hammer and thus increases the life. The direction of motor is reversed at regular intervals to have the uniform wear on hammers. Bevcon Hammer mills produce higher crushing ratios up to 25:1. Reversible Hammer Mill is used either as a primary, secondary or territory crusher depending on the capacity and circuit design.

Ribbon Blender

Get Price Quote

Ribbon Blender is designed for rapid and thorough blending, to eliminate product stagnation and rapid action the opposite ribbons rolls, tumbles and pushes the product in opposite direction longitudinally from both ends. The flow of material in opposite direction results in uniform and fast mixing. Seals: A Teflon bush, Oil seal and gland packing is provided to avoid leakage. (Silicon seal optional) Drives: The blender is provided with a suitable reduction gear box and motor to achieve required RPM Features Ribbon blender shell made of stainless steel The lid has 3 piece segment with fixed center piece and hinged cover at either sides for charging of products The lid has 3 piece segment with fixed center piece and hinged cover at either sides for charging of products The main shaft made of stainless steel on which the ribbons are welded The ribbon are made of stainless steel flats with suitable size and thickness depending up on the capacity

Hammer Mill

Get Price Quote

HM-I (without cyclone) Product Introduction: Our hammer mill is the special milling equipment for materials of < 50 mm (diameter), < 300 mm (length), such as tree trimmings, wood pieces, crop stalks, rice husk, cotton stalk, cottonseed skins and so on. The working principle This hammer mill contains some rotors which are mounted by many hammers. The hammers swing following with the rotor at a high speed. And then the materials fed into a feed hopper are shared by the hammers. At last the materials are expelled out and sieved by the exhaust fan and screen. After milled, the output size can reach diameter 3-5mm, which is suitable for further palletizing or Briquetting.

Screw Feeders

Get Price Quote

Material is extracted in batches from a silo and then fed into a weigh hopper. Feed rates of smaller screws are more accurate than those achieved with larger diameters. Consistently, larger Screw Feeders require micro-feed aids in order to improve their poor feeding accuracy.