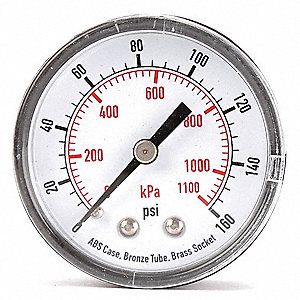

Water pressure gauge

Get Price Quote

100 Piece (MOQ)

Pressure Gauges

Get Price Quote

When selecting a pressure gauge, it is important to consider the following factors to ensure safety and accuracy: 1. Pressure fluid composition 2. Pressure fluid temperature 3. Ambient conditions 4. Pressure range 5. Conditions affecting wear of the system 6. Method of mounting 7. Required accuracy 1. Pressure fluid composition Since the sensing element of a pressure gauge may be exposed directly to the measured medium, consider the characteristics of this medium. It may be corrosive, it may solidify at various temperatures or it may contain solids that will leave deposits inside the sensing element. For pressure fluids that will not solidify under normal conditions or leave deposits, a Bourdon tube gauge is acceptable. Otherwise a Sealgauge or diaphragm seal should be used. A chemical compatibility chart follows this section to aid in the selection of the proper sensing element material. 2. Pressure fluid temperature Steam and other hot media may raise the temperature of the gauge components above safe working limits of the sealed joints. In these cases it is recommended that a siphon, cooling tower or diaphragm seal be used in conjunction with the pressure gauge. 3. Ambient conditions The normal ambient temperature range for WIKA pressure gauges is -40o F to +140o F (-40o C to +60o C) for dry or silicone-filled gauges and -4o F to +140o F (-20o C to +60o C) for glycerine-filled gauges. The error caused by temperature changes is +0.3% or -0.3% per 18o F rise or fall, respectively. The reference temperature is 70o F (20o C). The correction is for the temperature of the gauge, not the temperature of the measured medium. Remote gauge mounting using a diaphragm seal and capillary line is one alternative for applications involving extreme ambient temperature. Moisture and weather effects must also be considered. Liquid-filled gauges prevent condensation build up. For outdoor use, stainless steel, brass or plastic cased gauges are recommended. 4. Pressure range A gauge range of twice the working pressure is generally selected. The working pressure in all cases should be limited to 75% of the gauge range. Where alternating pressure and pulsation are encountered, working pressure should be limited to 2/3 of the gauge range. 5. Conditions affecting wear of the system In applications involving severe pressure fluctuation or pulsation, the use of restrictors and/or snubbers is recommended. In addition, liquid-filled gauges increase the service life of gauges in these conditions. WIKA liquidfilled gauges are generally filled with glycerine. Silicone for larger temperature extremes and Halocarbon® for use with oxidizing agents such as chlorine, oxygen and hydrogen peroxide are also available. 6. Method of mounting Radial (LM) and back (CBM or LBM) connections are available for most WIKA gauges. WIKA stocks gauges with standard NPT threaded connections. Other types such as metric threads, straight threads, hose barbs and special fittings are available as a special order. Pressure gauges should be mounted in the upright position. For applications where the gauge is mounted side ways, horizontally or upside down, contact WIKA Customer Service for gauge type compatibility. 7. Required accuracy WIKA stocks gauges with accuracies from ± 3/2/3% to ±0.1% of span (ASME Grade B to Grade 4A). To ensure safe and accurate gauge selection, you must take all of the above factors into consideration.

Best Deals from Baumer Pressure Gauge

Pressure Gauges

Get Price Quote

Pressure Gauges

Get Price Quote

We are offering pressure gauges. Pressure gauges of 2.5", 4", 6", 10" of different capacities are available with us in ready stock.

Pressure Gauge

1,460 Per Piece

Pressure Gauges

Get Price Quote

Selecting a pressure gauge when selecting a pressure gauge, it is important to consider the following factors to ensure safety and accuracy: 1. Pressure fluid composition 2. Pressure fluid temperature 3. Ambient conditions 4. Pressure range 5. Conditions affecting wear of the system 6. Method of mounting 7. Required accuracy

Analog Pressure Gauge

Get Price Quote

Pressure Gauges

Get Price Quote

Pressure Gauges

Get Price Quote

We have been able to Supply superior-quality Pressure Gauge. This gauge is widely used to measure pressure and vacuum in various industrial sectors. Our offered gauge is reckoned for its accurate measurement, fine finish and longer service life. High quality material is used that is procured from certified vendors in the manufacturing process of this gauge. Post-production, this gauge is thoroughly checked on various parameters to ensure optimum performance. We assure to deliver this Pressure Gauge within the promised time frame that is highly appreciated by patrons We are very well reputed for our quality and our sincere work. These pressure gauges are cased with pressed steel and stainless steel to improve their performance. These gauges are widely used to measure: Air Water Gas pressure (in various hydraulic and pneumatic application Our product is very safely and efficiently designed under the supervision of our highly diligent and hardworking man force such that it is structured to facilitate ensure safe, trouble-free performance. These are known or their brilliant functioning, quality material compatibility, adequate ratings, proper installation, easy operation and maintenance. Our product range includes Vacuum Gauges, Level Gauges and Liquid Level Gauges etc. Our sole aim is to put a smile of contentment on the faces of our customers and do our best in making that possible. Our offered range is manufactured using superior quality raw materials and advanced technology at the vendor’s end. While manufacturing the offered range of products, we lay special emphasis on the overall quality and durability. Additionally, our quality analysts keep an eye on the entire range to avoid any possibility of flaw.

Pressure Gauge

Get Price Quote

Pressure Gauge, compacting factor apparatus, Ultrasonic Pulse Velocity Tester

Pressure Gauges

Get Price Quote

We are offering pressure gauges. analogue differential pressure gauge mounts in industry standard holes • accuracy 2% • die cast aluminum housing (s2000) •diff erent pressure range to suit most of the application digital differential pressure gauge mounts in industry standard holes universal power 16 –265 vac vdc accuracy 1% (better available) large 0.5” led display weatherproof face 5 selectable engineering units opti&link™ optional 4-20 ma output

Pressure Gauge

Get Price Quote

Pressure Gauge, oxygen meter, Thermo Hygrometer, Temperature Transmitter

Pressure Gauges

Get Price Quote

Pressure Meter

Pressure Gauges

Get Price Quote

Pressure Gauges

Get Price Quote

Humidity Meters, Instruments, scada systems, thermo wells, Calibrators

Pressure Gauges

Get Price Quote

Transmitter, Temperature Sensors, indicator