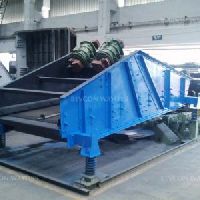

Vibrating Feeder

Bevcon wayors Pvt ltd offers a full line of vibrating feeders serving to the core industry like Thermal power, Steel, mining &cement etc. Vibrating feeder is one of the preliminary types of feeding arrangements. The discharge of material is possible through induced vibrations through electrically driven unbalanced motors. It is possible to generate elliptic, circular or linear vibrations through adjustable fly weights attached to the motors. The centrifugal force generated through theses weights is adjustable and hence variation in vibrations is achieved. Accurate discharge control achieved through the adjustment of centrifugal forces.

...more

Vibrating Conveyor

Vibrating conveyors are used to move materials from one place to another and can be individually tailored for a wide range of process applications with coil spring or contour composite spring components. Standard and custom designs are readily available to suit the application. Common design options include: Dust tight covers with quick release clamps, food grade construction, low profile, dynamic balancing, specialty trough finishes, abrasion resistant liners, magnetic separation, metal detection, air classification, cable suspension, high temperature designs, etc.

...more

Twin Shaft Hammer Crusher

It is typically used to reduce material to fine crushing. Most of the twin shaft hammer mills provide with bottom cage. The bottom cage is provided with suitable opening in order to ensure 100% process of required size. The feed material is processed between the two rotors and against a grinding jib. The crusher is manufactured with a robust fabricated steel body provided with hard liners. Hammers are specially designed with high work hardening steel like Manganese steel with different shapes. The rotor is suitably fabricated, machined and thus well balanced. Hammers are of high grade alloy steel selected according to the material specification and customer needs.

...more

Trommel Screen

A trommel screen, also known as rotary screen, is an essential unit which is used mainly in the mineral and solid-waste processing industries. It consists of a perforated cylindrical drum which is normally elevated at an angle at the feed end. Physical size separation is achieved as the feed material spirals down the rotating drum, where the undersized material smaller than the screen apertures passes through the screen, while the oversized material exits at the other end of the drum. Bevcon Trommel screens can be used in a variety of applications such as classification of solid waste and recovery of valuable minerals from raw materials. Trommels screen come in many designs such as concentric screens, series or parallel arrangement and each component has a few configurations. However depending on the application required, trommels have several advantages and limitations over other screening processes such as vibrating screens, grizzly screens, roller screens, Banana screens and gyratory screen separators.

...more

Stacker Cum Reclaimer

The central function of stockyards in the field of bulk materials handling lies in the buffering, blending and storage between incoming and outgoing materials. The stockyards for mines, power plants, beneficiation plants, ports and terminals are developed in a circular or longitudinal layout incorporating feed conveyors, stackers and reclaimers. Reclaimer is a large machine used in stockyard system applications. A reclaimer's function is to recover bulk material such as coal, ores and etc. from a stockpile. Reclaimers are volumetric machines and are rated in cubic meters per hour (m3h) for capacity, which is often converted to tonnes per hour (tph) based on the average bulk density of the material being reclaimed.

Feature : System Design. Drive Location and Selection. Take-up Performance Requirement. Static and Dynamic Analysis.

...more

Stacker Machine

The central function of stockyards in the field of bulk materials handling lies in the buffering, blending and storage between incoming and outgoing materials. The stockyards for mines, power plants, beneficiation plants, ports and terminals are developed in a circular or longitudinal layout incorporating feed conveyors, stackers and reclaimers. A stacker is a large machine used in stockyard system. Its function is to pile bulk material such as coal, limestone, ores and etc. on to a stockpile. Linear Longitudinal Stacker Stackers are nominally rated for capacity in tones per hour (tph). They normally travel on a rail between stockpiles in the stockyard. A stacker can usually move in at least two directions:

...more

Single Roll Crusher

Bevcon Single Roll Crusher is typically primary crusher. The crushing technique involves the operations like Impact, shear and compression. The material entered in the crushing chamber is struck hard against a rotor consisting of series of teeth mounted on a rotor. Material is crushed between teeth and a breaker plate consisting of hard liners. Providing a crushing ratio of up to 6:1, Bevcon Single Roll Crushers reduce large size particles in the feed to a medium size, while producing a low percentage of fines. The Single Roll Crusher design is very effective in reducing lumpy material because of the interrupted opening between the roll teeth and the corresponding grooves in the crushing plate liners.

...more

Ring granulator

Pressure granulation most often uses ring granulators. To ensure a proper course of pressure in granulation process, it is important that material is forced through holes which are set in a particular matrix. An adjustable cage consisting of set of holes is arranged in the crushing chamber. Bevcon ring granulators crush the material by the combination of impact and rolling compression. Product size is determined by the openings incorporated in the cage.The cage is so adjusted by changing the clearance between the cage and the path of grinding. Bevcon granulators are also provided with a tramp iron pockets (most of the times provided with magnets) to remove the un crushed foreign materials.

...more

Reversible Hammer Mill

Hammer Mills are very old yet widely used among various types of crushers. It is a type of centrifugal crusher. The crusher hammers are symmetrically designed on rotors and hence can work in both the directions. Reversal of the direction permits the user to use the opposite face of the hammer and thus increases the life. The direction of motor is reversed at regular intervals to have the uniform wear on hammers. Bevcon Hammer mills produce higher crushing ratios up to 25:1. Reversible Hammer Mill is used either as a primary, secondary or territory crusher depending on the capacity and circuit design.

...more

Reciprocating Feeder

Bevcon reciprocating feeder is mainly used for feeding various non-sticky materials. The reciprocating feeder can send massive and granular materials from feed bin to receiving device evenly and continuously. The reciprocating feeder has been widely used in the crushing and screening line of the industries of thermal power plants, beneficiation, sponge iron, cement and chemical industries etc.

...more

Lump Breaker

Bevcon Lump breakers, also known as lump crushers, able to reduce lumps created in the production, storage or transportation of bulk solids and powders in aggregates, chemicals, pharmaceuticals, foods, agricultural feeds and other materials to a consistent size as required without generating excessive dust and fines. Material that is stored becomes compacted and agglomerated. For instance, bagged powders can form lumps or even be solid lump in the lower layers, when stored on a pallet or exposure to humidity in the air. Lump breaker solves many processing problems including preparing of material for conveying, breaking up agglomerates and reducing material for further processing. Reducing lumps will make material easier to handle, improve material’s flow characteristics and make ready for secondary size reduction, by increasing the material’s surface area to improve efficiency for drying or for better mixing and finally ensure success of conveying, either in a pneumatic conveyor, belt conveyor, screw conveyor, or other conveying equipment.

...more

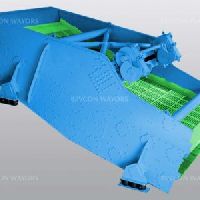

Linear Motion Screen

Linear motion vibrating screens differ from other screening systems.vibrations are caused through linear oscillating motion. The linear motion vibrating screens are very compact in design. Very low mounting heights can be achieved by installing these screens in horizontal and low inclination positions. Linear motion is produced by the action of two unbalanced motors mounted on screen body. Both the motors are mounted on machine cg point at an angle. The contra rotation of these motors provides pattern like straight line throw. Linear motion provides excellent performance even in high moisture applications. Screening media includes woven mesh, rubber and polyurethane modular panels.these vibrating screens are equipped with single and multiple screening decks.

...more

Jaw crusher

Bevcon jaw crushers are used for primary crushing in a mine or ore processing plant. Jaw crushers are developed to reduces large size rocks or any hardest ores and as well as soft rock, recycling, slag etc. by using compressive force for breaking of particle. Product is fed into the top of the jaw crusher by a vibrating grizzly feeder. Mechanical pressure is achieved by eccentric rotating drive shaft causes the two jaws of the crusher of which one jaw is fixed mounted in a “V” alignment stationary breaking surface, while the other reciprocates movable jaw exerts force on the rock by forcing it against the stationary plate. The space at the bottom of the “V” aligned jaw plates is the crusher product size gap or the size of the crushed product from the jaw crusher. The material remains in the jaws until it is small enough to pass through the gap at the bottom of the jaws.

...more

Impact Crusher

The word impact makes sense that in this particular type of crusher creates impact action while crushing the materials. Bevcon Impact crushers are non-reversible.Unlike hammer mills, the impact crusher rotors are provided with blow bars of single or segmented type depending on the size of the crusher. Bevcon Impact crushers are of horizontal type and produce fewer fines and thus emit no dust. Impact crusher offers high crushing ratios upto 30:1.Bevcon impact crushers effectively handle feed sizes beyond the range of conventional secondary crushers. The crusher is manufactured with a robust fabricated steel body provided with hard liners.

...more

Grizzly Feeder

Bevcon Vibrating grizzly feeder is a kind of linear direction feeding equipment. Grizzly Feeder is used to transfer the large size materials and granular materials from hopper to receiving device uniformly, periodically and continuously in the production flow and to feed materials into the crusher continuously and uniformly. The vibrating grizzly feeder is widely used to match the crushing and sieving equipments in many industries including metallurgy, coal mine, mineral dressing, building material, chemical, grinding, etc They are driven by highly reliable Direct Force Exciters, through drive motor and cardan shaft coupling. Bevcon Wayors Vibratory Grizzly feeders can offer capacities up to 2500 tons per hour and can typically handle single particle lumps up to 2.5 meter edge length. They can withstand high impact loads. Feeders which can handle single particle lumps of sizes up to 8.5 meters are custom made on request.

...more

Flip Flow Screen

Flip Flow Vibrating Screens are used to screen the material having high moisture and sticky in nature where the circular motion or any conventional mechanical vibrating screen becomes inadequate to cater the requirement. Bevcon flip flow screen motion is versatile compared to other flip flow screen technologies. The particle motion of Bevcon flip flow screen takes an elliptical path. This versatile motion extends a trampoline effect of screening media. Very high G forces up to 50G are achieved through this action. Flip flow screen consists of two baskets (Inner & outer) mounted on a common shaft. However the centre axis of both the baskets is not same but inner basket is having a slight eccentricity.

...more

feeder breaker

Feeder breaker is a conveying system which incorporates combination of scrapper chain conveyor and a pick type breaker to reduce the size of the material. Thus a feeder breaker forms a single piece of equipment with the above mentioned combination and installed at the location. Feeder breakers are a type of surface mine crushers and used to crush Run of mine ore. It is also used as in pit crusher at mine areas. Material is fed into a feed hopper directly from Mine dumpers. The chain conveyor conveys the lumps of material through the breaker which sizes the material by the force of sharp pointed picks striking down to the material. Thus the reduced material through the pick breaker is accurately sized and conveyed further.

...more

Double Roll Crusher

Bevcon toothed double roll crushers are equipped with two identical crushing rolls rotates towards each other. These crushers are ideal at different stages of crushing primarily envisaged to generate very less fines. Hence the crushing ratios are limited to 4 :1. Since both rolls rotate in same speed, there is no relative motion between roll surfaces. Material entered in crushing chamber is crushed between two crushing rolls. Crushing is accomplished purely by compressive action. In both the rolls one will be stationary and one is self adjustable

...more

Distribution Feeder

Distribution feeders are an integral part of large width screening machines | They uniformly distribute the material across the width of the screen at low velocity which enhances the screening accuracy | The distribution feeders are fitted with two unbalanced motors which control the federate by amplitude control | The feeders are self supported on Bevcon multi-deck Sizer frame: hence no other support in structure is required | They accept feed from relatively narrow and high speed feeding equipment like bucket elevator or belt conveyor and regulates flow uniformly to the Bevcon multi-deck Sizer

...more

Circular Motion Screen

When it comes to difficult material separation and demanding work atmosphere Bevcon Wayors is having more than 20 years of experience in many types of screening solutions. A circle-throw vibrating machine is a traditional (basic) type screening machine employed in processes involving particle separation. In screening processes the operation refers to separation of larger and smaller particles in a given feed material. As the name replicates, in Circular Motion vibrating screens, particle flow on screen will be in a circular path while performing separation process.

...more

apron chain belt conveyor

Bevcon Bulk Feeder is an above ground apron chain belt conveyor to convey varied bulk materials. This equipment provides a user friendly, cost effective and alternative to conventional below ground feeding & conveying system by eliminating huge civil works. Bevcon Bulk Feeder is capable of receiving varied bulk materials from all types of heavy duty vehicles like tipper trucks, truck tipplers and dumpers etc. Trucks trailers can rapidly discharge with minimum vehicle turnaround. Can convey volumetric capacities up to 300CumHr with maximum bulk density of 2.0 TonsCum. Can be used for conveying varied bulk materials like Coal, Pet coke, Iron Ore, Clinker, Limestone, Bauxite, Gypsum, Sand etc.

...more

Banana Screen

Banana screens are widely used in mineral processing industries and other industries because of its high efficiency and large capacities. The basic working principle is that the screen surface is partitioned according to the requirement of separation. At the feed end zone, the screening media is deep in slope due to which larger throw and high rate of material flow are achieved due to which the material layers thin and segregate quickly. At the middle section, the slope is reduced further to maintain normal throw and high material flow rate are applied to prompt segregated materials to penetrate through the screen aperture and segregate instantly.

...more

Shell Dome Stacker & Reclaimer

Wet Scrapper Conveyor

Be first to Rate

Rate This