POT PTFE BRIDGE BEARING

160 - 200 Per Ton

10 Pack(s) (MOQ)

A PTFE (polytetrafluoroethylene) pot bearing, also known as a PTFE sliding bearing or PTFE spherical bearing, is a type of structural bearing used in bridge construction and infrastructure projects. It is designed to accommodate movements, rotations, and loads between different structural components, such as bridge superstructures and substructures, while providing low friction and smooth sliding surfaces. The key features and characteristics of PTFE pot bearings include: 1. Material: PTFE, a high-performance fluoropolymer, is the main material used in PTFE pot bearings. PTFE offers excellent chemical resistance, low friction coefficient, high load-bearing capacity, and resistance to deformation and wear. 2. Design: PTFE pot bearings typically consist of a steel pot or housing that encloses a concave spherical PTFE disc or sliding surface. The PTFE disc provides the sliding capability, allowing movement and rotation between the bearing surfaces. 3. Load capacity: PTFE pot bearings are designed to support significant vertical loads while allowing movements in different directions. They can accommodate vertical loads, horizontal displacements, rotations, and even seismic forces, depending on the design and size of the bearing. 4. Friction reduction: PTFE's low friction coefficient helps to reduce friction and shear forces between the bearing surfaces. This allows for smooth and controlled movements, reducing wear and energy loss within the bearing system. 5. Durability and maintenance-free operation: PTFE pot bearings are known for their long-term durability and low maintenance requirements. PTFE's inherent resistance to corrosion, weathering, and aging ensures the longevity of the bearing, even in harsh environmental conditions. 6. Safety and reliability: PTFE pot bearings are engineered to meet stringent safety standards and regulations for structural bearings. They are designed to withstand heavy loads, provide stability, and ensure the structural integrity of bridges and other infrastructure elements. 7. Customization: PTFE pot bearings can be customized to meet specific project requirements, including load capacity, movement ranges, and dimensions. They are available in various sizes and configurations to accommodate different structural designs and loads. Proper installation and periodic inspection of PTFE pot bearings are essential to ensure their optimal performance. Regular maintenance and lubrication may be required, depending on the specific design and usage conditions of the bearings. It is important to consult with qualified engineers or professionals with experience in bridge construction and bearing systems to ensure the proper selection, installation, and maintenance of PTFE pot bearings in accordance with project requirements and industry standards.

Bridge Bearings

Get Price Quote

Best Deals from Bridge Bearings

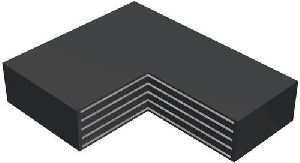

Elastomeric Bridge Bearings

Get Price Quote

Elastomeric Bridge Bearings are designed to transform the movement and rotation of bridge structure into elasticity and minimizes the secondary stress generated in bridge because of the layered rubber sheets reinforced by metal plates. These bearings are designed to accommodate vertical, longitudinal, horizontal and transverse loads movements and rotation of the superstructure caused by thermal effect, traffic loads, structural load, wind load, seismic load. These bearings effectively release the stress on the bridge and have excellent rotation in all the directions and movements. Elastomeric Bridge Bearings with simple reinforcement are made up of multiple elastomer layers separated by reinforcing steel plates moulded on the actual layers, and can be manufactured in a rectangular or circular shape to meet individual engineering requirements.

Elastomeric Bridge Bearing

Get Price Quote

We are offering elastomeric bridge bearing.

Bridge Bearing

Get Price Quote

We are the main supplier of this product.

Elastomeric Bridge Bearings

Get Price Quote

KANTAFLEX TM Elastomeric Bridge Bearings are designed to transform the movement and rotation of bridge structure into elasticity and minimizes the secondary stress generated in bridge because of the layered rubber sheets reinforced by metal plates. These bearings are designed to accommodate vertical, longitudinal, horizontal and transverse loads movements and rotation of the superstructure caused by thermal effect, traffic loads, structural load, wind load, seismic load etc. These bearings effectively release the stress on the bridge and have excellent rotation in all the directions and movements. The inserted metal plates restrict the rubber expansion on the sides and improve the resistance to load on the bridge as the elasticity of rubber absorbs shock well and lengthens the natural period of stress. Another advantage is the robustness and corrosion free nature of these products, ease and convenience of installation, long service life and customized size to suit the bridge design.

Bridge Bearings

Get Price Quote

Elastomeric bridge bearings are designed to transform the movement and rotation of bridge structure into elasticity and minimizes the secondary stress generated in bridge because of the layered rubber sheets reinforced by metal plates. These bearings are designed to accommodate vertical, longitudinal, horizontal and transverse loads movements and rotation of the superstructure caused by thermal effect, traffic loads, structural load, wind load, seismic load etc.

Elastomeric Bridge Bearings

Get Price Quote

Elastomeric Bridge Bearings, Rubber, Kerb Stone Moulds, tile moulds

Elastomeric Bridge Bearing

Get Price Quote

Elastomeric Bridge Bearing, Slab Seal Expansion Joint

Elastomeric Bridge Bearings

Get Price Quote

Elastomeric Bridge Bearings, Slab Seal Expansion Joint

Elastomeric Bridge Bearings

Get Price Quote

Elastomeric Bridge Bearings, Pvc Water Stopper, strip seal expansion joint