Paper Plate Die

950 Per inch

1 piece (MOQ)

compacting dies

Get Price Quote

We hold expertise in offering a wide range of Compacting Dies. Our products are manufactured from optimum quality components and under the firm direction of expert quality controllers. Owing to its ergonomic design, robust construction and high functional efficiency, these dies are widely used in various industries. Our product Compacting Dies are designed and developed as per international industrial standards and available at reasonable rates.

Best Deals from Casting Dies

taper die

Get Price Quote

Stainless Steel Soap Dies

280,000 Per Piece

5 Piece(s) (MOQ)

In order to ensure zero-defect quality, we conduct several tests on the products prior to final dispatch. As we are recognized as a dependable name in Hyderabad(India), we are capable of reaching any nook and corner with ease.

dehydrated Potato dies

Get Price Quote

Azista Industries is one of Indian’s food Ingredient Manufacturing Company in dehydrated apple. The company offers wide varieties of Dehydrated Fruits and Vegetables product with high-quality and a premium line of specialty ingredients used as a source for Ready to Eat Products Cereals.

Tungsten Carbide Dies

Get Price Quote

plastic mold die

10,000 Per Piece

10 Piece(s) (MOQ)

high pressure die casting die

1,800,000 Per Piece

The above hpdc- die designed and manufactured in house for simson engine (timing case),also we have production and componet suplying fecalities foe aluminium and zinc castings,for zinc castings for small components we have hot chamber die-casting machines for large quantity suply.the tool room is equiped with all high end machines,.

Deep Drawing Dies

Get Price Quote

When it comes to premium quality Deep Drawing Dies, then Amba Bhavani Toolcrafts is known as a one stop destination to obtain the same. Amba Bhavani Toolcrafts is an established Manufacturer and Supplier, offering superior quality Deep Drawing Dies. Made from the finest metal, our Deep Drawing Dies are quite robust and deliver flawless results. Our Deep Drawing Dies are precision engineer and dimensionally accurate. We are committed to offer Deep Drawing Dies at competitive market rates. Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

Plastic Dies

Get Price Quote

We make available Plastic Dies which are manufactured using high grade metals and in customized sizes. With meticulousness, hard work and commitment, our organization has developed in order to become a reputed trader in Hyderabad(India). Quality being the major concern of our organization, we keep a stringent check on the production, packaging and delivery processes.

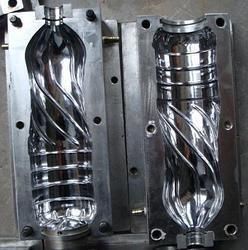

Water Bottle Die

Get Price Quote

Pellet mill Ring Dies

300,000 Per Piece

All kinds of pellet mill dies which suits to all types of pellet mills.we supply ring dies to that company with high quality to competitive price all over the year. We have never compromised on the quality to the customer. We believe in keeping the customers happy and providing them with products at a very competent price.

line dies

Get Price Quote

Line Dies when the budget is limited, production is low or the part needs to be turned over or rotated in any axis. They feature: Hand (human) or Robotic loading Multiple stations can be in a single die set Cast or plate die construction Standard parts from Dayton, Danly, Fibro, Dadco etc. Forming Simulation 3D at every stage - from Design to Machining In-house Tryout & Buyoff Early parts

Paper Plate Machine Dies

Get Price Quote

Our Paper Plate Machine Dies are demanded all across the country for their high performance and hassle-free working. These Paper Plate Machine Dies are widely used by the manufacturer of paper plates and in cottage industry. We also provide customize packaging of Paper Plate Machine Dies but at extra cost as applicable. Can make plates in any Thickness of Paper from : 80 GSM to 500 GSM Makes Plates Using Silver LaminatedITC White BoardAreca LeafBanana Leaf Price : Range starts from Rs. 2000 to Rs. 9000 for sizes from 4 Inches to 16 Inches.

fin dies

Get Price Quote

dvb D+E manufactures state-of-the-art fin dies for air conditioner and refrigerator heat exchangers. Our dies are drop-in replacements for Burr Oak or Tridan fin dies. They feature: Flat and V-Waffle (corrugated) surfaces Louvered or Lanced fin enchancement 1, 2 or 4 hole fin progression Feed Progression changer (optional) Adjustable collar heights Rippled or Straight edges Externally or Internally actuated pull feed systems CPM and / or coated cutting elements (optional)

Valve Forging Dies

Get Price Quote

Extensive market research and survey is conducted by us to ensure that an exclusive range of Draw Dies are offered by us. Production process is carried under the strict quality control of our quality monitoring experts, who have years of experience. Utilization of sophisticated designing patterns enables us to design our range as per set industrial trends. We ensure safe dispatch of our Draw Dies at our customer's premises.

Single Dies

Get Price Quote

We are listed at the apex in the list of the most preeminent Single Dies manufacturers in india. The unmatched quality and inexplicable performance of the single tool dies in respective application has attracted various customers to place bulk orders. Moreover, the single head dies offered by us are designed to get fitted either electric or pneumatic oscillating knife chuck. Further notable features like high durability and huge tensile strength have played a vital role in the enhancement of the demand of single dies. Customers are also eased with the availability of single tool cutting head dies that can process materials up to the thickness of 100mm.

PDC Dies

Get Price Quote

Win Tools uses the raw materials from world leaders like ASSAB and BUDEROUS and PDC dies are either vacuum hardened or regular hardened, in tune with customers' requirement. During design of feed system for PDC Dies, we involve all senior members of design, tool manufacturing, die casting and product design, apart from the customers themselves, And based on the outcome, we design the sprue, runner, gating and overflow, venting by using 3D modeling with international standards. Obviously, our PDC dies have proven longer tool life and high productivity.

Injection Moulding Dies

Get Price Quote

The company is a prominent Manufacturer, Exporter & Supplier of Injection Moulding Dies. The Injection Moulding Dies, offered by the company, are known for their flawless operations and long life. The company is offering a quality range of the Injection Moulding Dies at the market leading prices across the global markets. Working Plastic Granules are poured into the hopper and are heated up in the plasticing cylinder. The hydraulic or pneumatic ram forces the molten plastic out through the injection nozzle. (The exit to the hopper is closed off so that the molten plastic cannot escape back up into the hopper). The Molten plastic enters the injection molding die under great pressure so that it fills every part of the die cavity. (It is important that the die is preheated so that the plastic does not solidify on contact with the cold steel and block the sprue hole)The die is clamped together under considerable pressure so that the molten plastic cannot seep out through the joins. Guide pins ensure that the die parts line up accurately to give a good quality product. If the die pins wear and become loose the two halves of the product will be misaligned. The internal surface of the mould is finished to a high standard � either polished or textured. Advantages of Injection Molding Injection molded products are usually of high qualityFinish of the mould can be polished or texturedInjection molding can produce product very quickly especially if the machines are automatedA wide range of thermoplastics can be injected successfullyGenerates lots of cheap/disposable plastic products

Press Tool Dies

Get Price Quote

We are offering forming of atomic reactor bottom dish from 25mm thk copper plate by designing of press tool and loaned into a 400ton power press to form the job.

Tungsten Carbide Block

Get Price Quote

electro spark coating is a pulsed-micro welding process for depositing a hard wear resistant electrode material on a wide range of metallic substrates. The material to be coated serves as the anode while the cathode is the work piece itself. Striking an arc between the consumable anode and the job causes some of the electrode material to melt instantaneously at the point of contact and deposits on the surface of the work piece. The consumable electrode can be fixed in a vibrating holder for repetitive arcing to build-up coating thickness. Depending on the area to be treated electrode must be moved in a fashion similar to the welding process. The unit consists of a transformer, capacitor bank and a mosfet to impart necessary voltage, spark energy and pulse frequency. A rotating tool electrode holder is an important accessory for applying the coating using metallic electrodes on larger surfaces and for mechanisation of the process. The process, which necessarily requires the substrate material to be conducting, is particularly well suited for localized area coatings, rebuilding the worn areas and can also be conveniently employed on components having complicated geometries.

Rotary Cutting Dies

Get Price Quote

Paper Plate Making Die

Get Price Quote

We are one of the well-known manufacturer and supplier of Paper Plate Making Die. The offered paper plate-making die is widely used for making paper plates, paper bowl and paper dona. Our supplied paper plate-making die is dimensionally accurate; to produce optimally sized paper plates. The offered paper plate-making die is made from high-grade raw material, which is sourced from very reliable vendors in the market. Features:Long DurabilitySturdy constructionHigh Performance Die Sizes:Mould -Item Name Paper Size (Inches)Bowl / Dona 5 numberBowl / Dona 6 numberBowl / Dona 7 numberBowl / Dona 8 numberPaper Plate / Kangura Die 6 numberPaper Plate / Kangura Die 7 numberPaper Plate / Kangura Die 8 numberPaper Plate / Kangura Die 9 numberPaper Plate / Kangura Die 10 numberPaper Plate / Kangura Die 11 numberPaper Plate / Kangura Die 12 numberPaper Plate / Kangura Die 13 numberPaper Plate / Kangura Die 14 numberThali Dec mould 12 numberThali Dec mould 13 numberBuffet Thali Mould 12 number

Circular Thread Rolling Die

16,000 - 25,000 Per Unit

Split dies

Get Price Quote

Thread Rolling Dies

15,000 Per

Thread Rolling Dies, Circular Thread Rolls, serration rolls

Forging Dies

Get Price Quote

Forging Dies, CNC Machined Component, Forged Components, Die Casting

Avr Paper Plate Machine Double die

Get Price Quote

Paper Plate Die

Get Price Quote

Paper Plate Die, Paper Bowl Making Machine, Paper Glasses, Paper Bowls

pressure diecasting dies

Get Price Quote

pressure diecasting dies