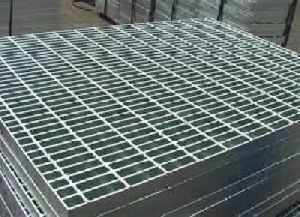

WALKWAY GRATINGS RACK

We are passionately engaged in offering an exclusive range of Floor Gratings for offshore applications and corrosive chemicals, these floor gratings are designed utilizing the supreme quality material and leading techniques in accordance with the market standards. Our team of quality controllers checks all floor gratings before delivering to customers. Additionally, these floor gratings can also be provided by patrons in several specifications as per the varied needs of clients. Features: Durable finish Fire Retardant Easy to assemble Applications: Chemical Plant & Refineries Power Plants Swimming Pools Electroplating Platform Trench Cover Marine Industries Battery Racks Pretreatment The Pre-treatment used before the powder coating is called as 7 tank cleaning. It is done before applying the powder coat to the metal or aluminum. This 7 tank process for powder coating is initially important to perform before the rest of the processes. We provide the better service for hot process cleaning and the product is then coated well after the process. Our tanks are made up of Poly Propylene. The tank treatment includes the following stages. 1. Prior, the metal is first kept inside the Poly Propylene for mere 20 minutes. 2. It is then rinsed in another tank. 3. After taking it in the third tank, the metal is then de-rusted. 4. After 20 minutes of de-rusting, it is then rinsed with water in another tank for a minute. 5. It is then kept ideally in another one for compact crystal structure. 6. The metal is then immersed inside a chemical for 20 minutes, which helps in the formation of compact crystal. 7. The metal is then rinsed in water again. Then it is immersed inside the chemical that helps in preventing the corrosion. 8. Later it is taken out in the air for further process. After this, the metal is taken for the powder coating. When the coating is done the metal is then heated under certain conditions. Later comes the curing part where we do finishing touch on the metal. We will do anything in order to make your product look good. 7 tank cleaning services are our prior most service among the rest. 7 tank cleaning and powder coating are the two superior most processes that would help your products better. The resulting product will be strong enough to be used in anyway.

...more

Slotted Angle Shelving System

We are manufacturer and supplier of Slotted Angle and Slotted Angle Racks. Racks are suitable for storing records and it’s the cheapest way to store items as compared to other storage materials. We also Fabricate Stainless Steel Storage Racks, Two tier Structures, Partitions in racks, Racks With Cladding Sheet, Open All side Racks and All Side closed Racks. Slotted angle helps you build an efficient framing system for a variety of uses from machine guards to hand rails. Slotted Angle is the most versatile, time and cost effective construction material available for building carts, ladders, benches, shelving, cases, racks or any other type of structure. It is made of either 12 or 14 gauge roll-formed steel. A complete space management solution provider, we also offer to our clients a fine range of accessories for slotted angles and slotted racks. Manufactured using quality raw material and customized as per the requirements of the clients, this range has many options and models. Some of these accessories are section panels, steel panels, steel shelves and floor gratings. A complete space management solution provider, we also offer to our clients a fine range of accessories for slotted angles and slotted racks. Manufactured using quality raw material and customized as per the requirements of the clients, this range has many options and models.

...more

Powder Coating Plant

Powder coating is a type of coating that is applied as a free flowing dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured in an oven, typically 200 degrees), to allow it to flow and form a "skin". Powder coating is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as gates, railings, and automobile and bicycle parts. Newer technologies allow other materials, such as MDF to be powder coated using different methods. Advantages: Powder coatings emit zero or near zero volatile organic compounds (VOC) Powder coatings can produce much thicker coatings than conventional liquid coatings without running or sagging. Powder coating over spray can be recycled and thus it is possible to achieve nearly 100% use of the coating Powder coating production lines produce less hazardous waste than conventional liquid coatings. Capital equipment and operating costs for a powder line are generally less than for conventional liquid lines. Powder coated items generally have fewer appearance differences between horizontally coated surfaces and vertically coated surfaces than liquid coated items. A wide range of speciality effects is easily accomplished which would be impossible to achieve with other coating processes.

...more

light duty storage racks

We are the leading manufacturer & supplier of Light Duty Storage Racks. Our racks are ordered in bulk assortments by various departmental stores and shops. These racks are provided at the customers' stipulated place within the set time frame. Features: Light in weight Durable finish standard Breakage resistant Electrical Panel Board Our company is involved in the manufacture of a high quality of Bus Ducts which are made using the best technology available in the market and the best materials are used. Our products are available at very reasonable rates in the market and they are delivered to the customers on the right time as per the customer specifications. Our products are very durable and they offer a high performance to the customers and offer a long lasting service life to the clients.

...more

GALVANIZED DECKING PANELS

Support Bars for Heavy Duty Racking system. We provide all compatible sizes of galvanized decking panels for Heavy Duty Racking systems.

...moreBe first to Rate

Rate ThisOpening Hours