Conveyor Idlers

Get Price Quote

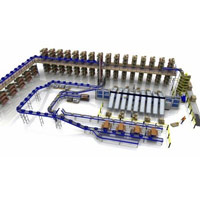

Idlers are the heart of a conveyor, since reliability and longer life can reduce down time for the conveyors, effect reduction in power consumption and increase belt life. Steel infratech idlers operate with very low coefficient of friction and are designed for reliable and guaranteed performance of upto 60,000 hours. Troughing Flat Carrying Idlers Troughing Flat Impact Idlers Self Aligning CarryingReturn Idlers Flat V Roll Return Idlers Self Cleaning Return Idlers

Rubber Conveyor Belts

800 - 1,800 Per Meter

50 Meter (MOQ)

Sandhya Enterprises supplier of Rubber Conveyor Belts. size: 1.6mm Thickness 2Ply to 3ply 2.8.0mm Thickness 2ply to 3ply 3.10.mm Thickness 3 to 4ply 4.12.0mm Thickness 3 to 4ply Width 100mm to 1500mm. Use for RMC Plant , Cement Plant and Crusher Plant.Conveyor belts are mechanical devices used to transport materials or objects from one point to another in a continuous manner. They are widely used in various industries, including manufacturing, mining, agriculture, logistics, and more. Conveyor belts consist of a continuous loop of flexible material that is driven by pulleys or rollers, allowing for efficient movement of goods or materials. Here are some key features and components of conveyor belts: 1. Belt material: Conveyor belts are typically made from various materials depending on the specific application requirements. Common belt materials include rubber, PVC (polyvinyl chloride), polyester, nylon, metal, or a combination of these materials. The choice of material depends on factors such as the type of material being conveyed, its weight, abrasion resistance, temperature resistance, and environmental conditions. 2. Belt structure: Conveyor belts are constructed with layers of material that provide strength, flexibility, and durability. The most common belt structure consists of a carcass, which is the core layer that provides tensile strength, and one or more cover layers that protect the carcass from wear, abrasion, and external elements. 3. Drive system: Conveyor belts are driven by a motorized pulley, drum, or a set of rollers. The drive system applies power to the belt, causing it to move. The drive can be located at either end of the conveyor or at intermediate points, depending on the length and configuration of the conveyor system. 4. Rollers and idlers: Conveyor belts run on rollers or idlers, which support and guide the belt along the conveyor path. These rollers can be made of steel, rubber, or other materials, and are designed to minimize friction and facilitate smooth movement of the belt. 5. Belt tracking system: To ensure proper alignment and tracking of the belt, conveyor systems may include a tracking mechanism. This can be in the form of adjustable idlers or automated systems that help keep the belt centered and aligned on the conveyor. 6. Accessories: Various accessories can be added to conveyor belts to enhance their functionality and safety. These may include belt cleaners to remove debris and material buildup, belt fasteners for joining belt ends, skirt boards to contain material on the belt, and safety devices such as emergency stop switches and belt misalignment sensors. 7. Specialized belts: There are specialized conveyor belts designed for specific applications, such as heat-resistant belts for high-temperature environments, food-grade belts for the food industry, oil-resistant belts for the mining industry, and more. These belts are formulated with specific materials and features to meet the unique requirements of their respective industries. Proper maintenance and regular inspection of conveyor belts are crucial to ensure their efficient and safe operation. This includes monitoring belt tension, checking for wear or damage, and performing routine cleaning and lubrication. When selecting a conveyor belt, it is important to consider factors such as the type and weight of the material being conveyed, the operating conditions (including temperature, humidity, and presence of chemicals), the required speed and capacity, and any specific industry regulations or standards. Consulting with experienced conveyor belt suppliers or manufacturers can help in choosing the appropriate belt type and configuration for your specific application needs.

Best Deals from Conveyor Components

Air Slides with Blowers

Get Price Quote

Air Slide without the use of moving parts, these gravity conveyor transport fine, dry bulk materials, with a minimum of abrasive wear on the conveyor. Dry materials flows down inclined conveyor, fluidized by low-pressure air entering beneath porous medium. The Air Slide conveyor is easily installed , with simple floor or overhead support which released valuable floor space for other used. Operation is dustless and noiseless with extremely low power consumption. Conveyor line needs no lubrication ,and is self-cleaning ,so there is almost no maintenance

Belt Scale Conveyor Belt

Get Price Quote

Electronic conveyor belt scale system enables the weighing of bulk materials carried by conveyor belts during the conveying process. The flow amount (capacity) is proportional to the speed and the material on the belt. Conveyor Belt Unit With Idler(s); They are designed to fit every kind of conveyor belts used in the industry and located in place of one or a group of idlers where the belt moves on. The unit is a steel construction which realizes the weight of the bulk material on the belt by means of load cells. Depending on the single-idler group construction (SIB) with two load cells or multi-idler group construction (MIB) with 4 load cells are used. The protection is IP68 class. Both, MIB construction and SIB construction offer the same high level of accuracy which is approved by tests in ESIT Laboratories. The load cells have an IP68 class protection while the indicator has IP66 grade protection. Control Terminal; The measured value is displayed digitally by the microprocessor based model LCA control device. Daily, statistical data can be prepared and printed if LCA terminal is connected to DLMS software.

Guide Wear Strip

1,650 Per Kilogram

Grid Magnet Separator

Get Price Quote

We are offering grid magnet separator. Applications attracts tramp iron pieces from inflow of materials in hopper. Used particularly in plastic, chemicals, grains, cosmetics processing for powder separation. Concentrated magnetic field in the magnetic rod provides high grade attraction. Optional: with 100% stainless steel construction. Grid with rate earth ndfeb magnets can be made at extra cost. Features high power, low cost magnetic plates for inflow separation in hopper. Made with strontium ferrite or rare earth ndfeb magnets. Circular or rectangular shape with ss body. Single or double unit for better separation. High temperature grids made with alnico magnets. Magnet can be easily removed for cleaning.

Idler Stand

Get Price Quote

Conveyor Roller

Get Price Quote

Conveyor Parts

Get Price Quote

A prominent supplier of huge range of Conveyor Parts.

cleated belt conveyors

Get Price Quote

cleated belt conveyors, Industrial Dust Collector 1, Centrifugal Blower

Rubber Conveyor Belts

Get Price Quote

Rubber Conveyor Belts, Cast Iron Bearing Housings, Conveyor Idlers, Bearings

Magnetic Separators

Get Price Quote

Magnetic Separators, chucks

Conveyor Belt

Get Price Quote

Sand Screening Machine, Industrial Conveyor

Kiln Support Roller

Get Price Quote

Kiln Support Roller, Lime Calcination Plant, Automatic BURNT LIME PLANT

Roller Conveyor Belt

Get Price Quote

Roller Conveyor Belt

Idler Rollers

Get Price Quote

Carrying Idler Frame

mild steel roller

Get Price Quote

mild steel roller, stainless steel trusses, Water Pipeline Work

Belt Conveyor Head Pulleys

Get Price Quote

Belt Conveyor Head Pulleys, Crowned Tail Pulleys

Conveyor belts

Get Price Quote

Fabrication Works, Structural, Industrial Belts

Industrial Rollers

Get Price Quote

Brackets, cast iron, Gear Wheels, wire rope drums

Conveyor Belt

Get Price Quote

Air Blower, Ducting, Chimney, Tanks

Conveyor screws

Get Price Quote

Conveyor screws, Hanger Bearings, Cement Bag Feeding Systems

Conveyor belts

Get Price Quote

double crimped mesh, single crimped mesh, rubber beading, steel crimped mesh

Excavator Idler

Get Price Quote

Excavator Rock Breaker Chisel, Excavator Sprocket Wheel