Vibro Sifter

Vibro separators are circular gyratory screens used to separate solids from solids and liquid from solid. Vibro Sifter consists of Specially Designed Motor mounted vertically at the center of the base plate of the Screen. The Screen is in between feeding hopper and bowl. The material is fed on to the centre of top screen. The undersize material passes rapidly through the screen during its travel to the periphery. The over size material get continuously discharged through a tangential outlet. This is achieved by specially designed Vibratory Motor along with eccentric Top and Bottom Weights

...more

Vibro Screen

Vibro Screens are designed to perform effective size based separation in coarse as well as fine sizes. Vibro Screens use wire mesh or perforated or slotted sheets for carrying out separation of material on basis of size. Vibro Screens are designed on the principle of Accentric Gyratory Motion and are one of the most versatile and universally adaptable machines working across spectrum of industries.

...more

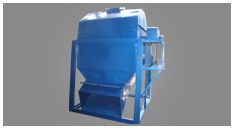

U Shape Blender

U Shape Blender cum Roaster for roasting of Coriander and Masalas raw material . U shape blenders are used to mix many thousands of products, from fertilizers and plastic resins to flavored coffees and cosmetics. The U shape blender is one of the most common mixing devices in service today, because it is one of the most versatile and cost-efficient mixers ever created. Its simple design makes it relatively easy to build. Simplicity also ensures easy maintenance.

...more

Tobacco Dust Cleaning Machines

Storage Bins

Roasters for Garam Masala

Roaster for roasting of Coriander and Masalas raw material . U shape blenders are used to mix many thousands of products, from fertilizers and plastic resins to flavored coffees and cosmetics. The U shape blender is one of the most common mixing devices in service today, because it is one of the most versatile and cost-efficient mixers ever created. Its simple design makes it relatively easy to build. Simplicity also ensures easy maintenance.

...more

Ribbon Blenders

Essaar machineotech Ribbon Blender is primarily designed for use with dry materials, although gas and liquid streams can also be introduced.

...more

Pickle blender

Paddle Blenders consist of a U-shaped shaped horizontal trough and a fabricated paddle agitator. The paddle agitator includes multiple paddles positioned to move materials in opposing lateral directions and radially. The paddle design is normally applied where friable materials are being blended and when batches as small as 15% of the total capacity are going to be mixed in one blender. Paddle designs are available in various capacities from 25 kgs to 1000 kgs per batch. Mostly in.

...more

Multi Mill

We offer multi mill that is a self controlled portable unit useful for high speed granulating, pulverizing, mixing, shredding and chopping, etc., The multi mills we offer are ideal for dry and wet granules and offers higher output with process standardization

...more

Mini Laboratory Pulveriser

mini blender

We offer mini blender that is used in assortment of industries. It is an efficient and versatile machine used for mixing dry powder and granules homogeneously. All the contact parts of the blender are made from SS with grades as required by customers. Our mini blender offers uniform mixing and easy discharge of material. As per customer requirement machine will be provided with left side drive or with right side drive. Maximum care has been taken to ensure safe operation of the unit. Worm reduction gear or chain sprockets will be used for speed reduction.

...more

micro pulveriser

Our Pulverizer consists of a rotor assembly fitted with beaters depend upon the grinding of material (Carbide tip, T type and Hard welding hammers) is generally operated at high speeds ( 2880 RPM). The grinding action in all the pulverizers is due to the impact between rapidly moving beaters & the particle itself. The energy of the moving hammers is dissipated into the particles being ground by virtue of their inertia, thus causing the particle size reduction. The machine is available in different sizes 1 HP to 75 HP - output depends on material and mesh

...more

Material Handling Equipments

Bucket Elevators, Rotor Lifts, Screw Conveyors, Belt conveyors Screw conveyors are volumetric conveying devices. With each revolution of the screw, a fixed volume of material is discharged. The purpose of a screw conveyor is to transfer product from one point to the next. Screw conveyors are always control fed at the inlet by another conveyor or metering device The device consisted of a hollow cylinder with a center shaft and a spiral fixed to the inner wall of the cylinder and center shaft. As the assembly rotated

...more

ipc container

Made in stainless steel 304 and 316 - Available from 50 Ltrs to 200 Ltrs.

...more

Hammer Mill Cutters

Herbal and other fibrous material for coarse products

Dust Proof Polishing Machines

Multipurpose dust proof polishing machine is for polishing of various materials to clear or clean the surface area suitable for Turmeric, Coconut Shell and Roots etc., Waste material and dust will be collected separately. The duration of the process will be approximately 15 to 20 minutes per batch and also differ from material to material. The machine is available in different sizes 50 Kgs to 1000 kgs per batch

...more

Dry and Wet Pulverizer

Ginger, Garlic, Onion coconut paste

Double Cone Blender

We offer double cone blender that is used in assortment of industries. It is an efficient and versatile machine used for mixing dry powder and granules homogeneously. All the contact parts of the blender are made from SS with grades as required by customers. Our double cone blender offers uniform mixing and easy discharge of material. The double cone blender is applicable for Pharmaceutical, Food, Chemical and Cosmetic products.

...more

Cone Pulveriser

The Cone type Pulveriser consists of an encased Rotor carrying swing hammers, whizzer classifier for fineness regulation and pressure gradient creator mounted on a solid shaft. Raw material to be pulverized enters the crushing chamber through the hopper. The impact of the hammers on the feed material against the liner plates reduces it into fine powder. The ground material is carried towards the whizzer classifier for classification and the oversize particles are rejected by the classifier and returned to the crushing chamber for further grinding. The classified material is then conveyed into the Cyclone for collection and bagging. A dust collector and airlock will be provided with additional cost in the system for ensuring dustless operation and for no loss of ground powder.

...more

Air Lock Valve

For all types of powder and Course material which needs air locking on output area or use for Dust priventive

...more

Chillies

Coriander

Spices

raagi powder

Be first to Rate

Rate ThisOpening Hours